Troubleshooting

Troubleshooting

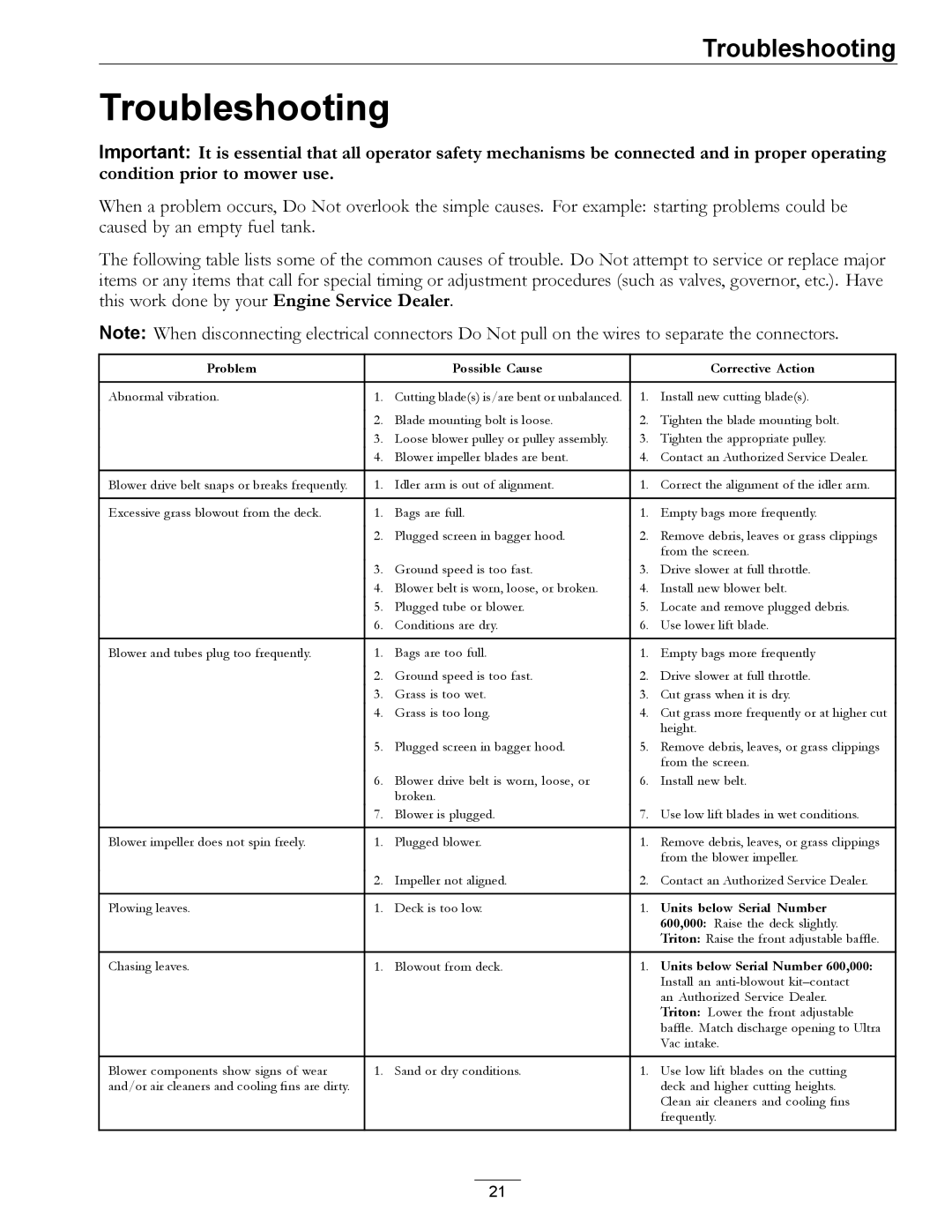

Important: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use.

When a problem occurs, Do Not overlook the simple causes. For example: starting problems could be caused by an empty fuel tank.

The following table lists some of the common causes of trouble. Do Not attempt to service or replace major items or any items that call for special timing or adjustment procedures (such as valves, governor, etc.). Have this work done by your Engine Service Dealer.

Note: When disconnecting electrical connectors Do Not pull on the wires to separate the connectors.

Problem |

| Possible Cause |

| Corrective Action |

|

|

|

|

|

Abnormal vibration. | 1. | Cutting blade(s) is/are bent or unbalanced. | 1. | Install new cutting blade(s). |

| 2. | Blade mounting bolt is loose. | 2. | Tighten the blade mounting bolt. |

| 3. | Loose blower pulley or pulley assembly. | 3. | Tighten the appropriate pulley. |

| 4. | Blower impeller blades are bent. | 4. | Contact an Authorized Service Dealer. |

|

|

|

|

|

Blower drive belt snaps or breaks frequently. | 1. | Idler arm is out of alignment. | 1. | Correct the alignment of the idler arm. |

|

|

|

|

|

Excessive grass blowout from the deck. | 1. | Bags are full. | 1. | Empty bags more frequently. |

| 2. | Plugged screen in bagger hood. | 2. | Remove debris, leaves or grass clippings |

|

|

|

| from the screen. |

| 3. | Ground speed is too fast. | 3. | Drive slower at full throttle. |

| 4. | Blower belt is worn, loose, or broken. | 4. | Install new blower belt. |

| 5. | Plugged tube or blower. | 5. | Locate and remove plugged debris. |

| 6. | Conditions are dry. | 6. | Use lower lift blade. |

|

|

|

|

|

Blower and tubes plug too frequently. | 1. | Bags are too full. | 1. | Empty bags more frequently |

| 2. | Ground speed is too fast. | 2. | Drive slower at full throttle. |

| 3. | Grass is too wet. | 3. | Cut grass when it is dry. |

| 4. | Grass is too long. | 4. | Cut grass more frequently or at higher cut |

|

|

|

| height. |

| 5. | Plugged screen in bagger hood. | 5. | Remove debris, leaves, or grass clippings |

|

|

|

| from the screen. |

| 6. | Blower drive belt is worn, loose, or | 6. | Install new belt. |

|

| broken. |

|

|

| 7. | Blower is plugged. | 7. | Use low lift blades in wet conditions. |

|

|

|

|

|

Blower impeller does not spin freely. | 1. | Plugged blower. | 1. | Remove debris, leaves, or grass clippings |

|

|

|

| from the blower impeller. |

| 2. | Impeller not aligned. | 2. | Contact an Authorized Service Dealer. |

|

|

|

|

|

Plowing leaves. | 1. | Deck is too low. | 1. | Units below Serial Number |

|

|

|

| 600,000: Raise the deck slightly. |

|

|

|

| Triton: Raise the front adjustable baffle. |

Chasing leaves. | 1. | Blowout from deck. | 1. | Units below Serial Number 600,000: |

|

|

|

| Install an |

|

|

|

| an Authorized Service Dealer. |

|

|

|

| Triton: Lower the front adjustable |

|

|

|

| baffle. Match discharge opening to Ultra |

|

|

|

| Vac intake. |

|

|

|

|

|

Blower components show signs of wear | 1. | Sand or dry conditions. | 1. | Use low lift blades on the cutting |

and/or air cleaners and cooling fins are dirty. |

|

|

| deck and higher cutting heights. |

|

|

|

| Clean air cleaners and cooling fins |

|

|

|

| frequently. |

|

|

|

|

|

21