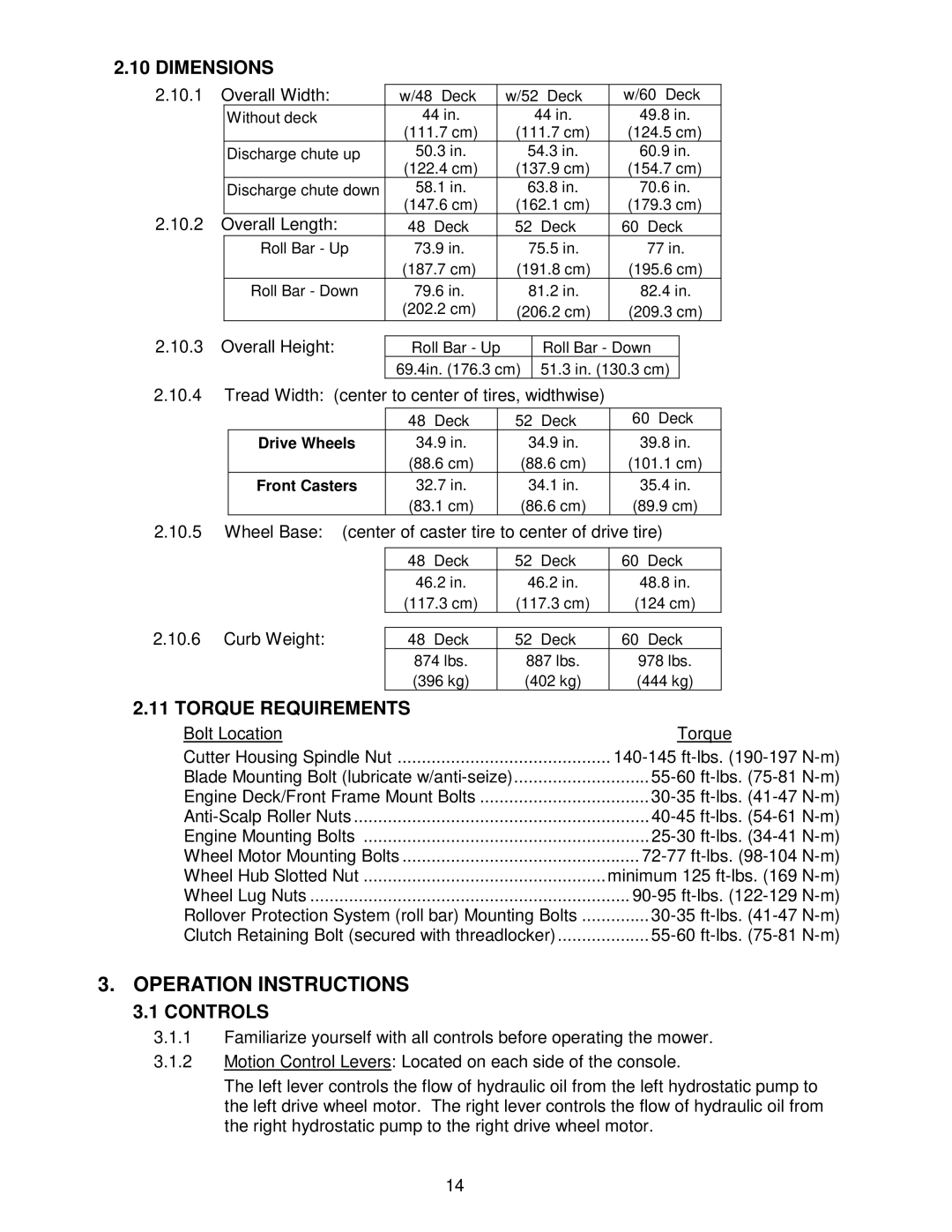

Lazer Z CT specifications

The Exmark Lazer Z CT is a standout zero-turn mower designed for both residential and commercial landscaping professionals who demand efficiency, durability, and cutting precision. This powerful mower has redefined the standards for productivity in the turf care industry, making it a popular choice among operators who handle regular and extensive mowing tasks.One of the main features of the Lazer Z CT is its robust cutting system, which is built to deliver an exceptional quality of cut. The mower is equipped with Exmark's patented Optimized Cutting System, which includes advanced engine and deck designs that work together to deliver superior performance. With deck options ranging from 48 to 60 inches, the Lazer Z CT caters to a variety of mowing needs, allowing operators to choose the right size for their landscape.

The Lazer Z CT is powered by a range of high-performance engines, including the reliable Kohler and Kawasaki offerings. These engines are engineered for maximum torque and power, ensuring that the mower can handle tough mowing conditions with ease. The advanced cooling systems also help to prolong engine life and reduce downtime, making this mower a dependable workhorse.

In terms of technology, the Lazer Z CT features a user-friendly control system that enhances maneuverability and comfort. The intuitive control levers allow for precise handling, especially in tight spaces and around obstacles. Additionally, the padded seat and ergonomic design ensure that operators can work for extended periods without discomfort.

Another notable characteristic of the Lazer Z CT is its exceptional build quality. Constructed with heavy-duty materials, the mower is engineered to withstand the rigors of daily use. Features such as the durable steel frame and commercial-grade transmission add to its longevity, making it a sound investment for lawn care professionals.

Furthermore, the mower's maintenance-friendly design simplifies routine upkeep tasks. Features like the accessible oil filter and easy-to-reach greasing points make it convenient for operators to perform regular maintenance, ensuring the mower remains in peak condition.

In conclusion, the Exmark Lazer Z CT combines power, precision, and comfort in a zero-turn mower that meets the demands of both residential and commercial applications. With its innovative technologies and robust features, it is an excellent choice for anyone looking to enhance their mowing efficiency and quality.