Maintenance

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Lubricate fittings with one to two pumps of NGLI grade #2

Refer to the following chart for fitting locations and lubrication schedule.

Lubrication Chart

Fitting | Initial | Number of | Service |

Locations | Pumps | Places | Interval |

1. Pivot | 2 | 2 | 50 Hours |

Arms |

|

|

|

2. Gear | 1 | 1 | 100 Hours |

Case |

|

|

|

Lubricate the Gear Case (Self-Propelled Units Only)

Service Interval: Yearly

1.Stop engine, wait for all moving parts to stop.

2.Remove the grass bag.

3.Install a grease gun onto the fitting through the belt cover opening

Figure 28

1. Grease fitting | 2. Belt cover |

4.Gently apply one to two pumps of #2

5.Install the grass bag.

Check Spark Plugs

Service Interval: Every 100 hours

1.Stop the engine and wait for all moving parts to stop.

2.Disconnect the wire from the spark plug (Figure 9 and Figure 10).

3.Clean around the spark plug.

4.Remove the spark plug from the cylinder head.

Note: Replace a cracked, fouled, or dirty spark plug. Do Not clean the electrodes because grit entering the cylinder can damage the engine.

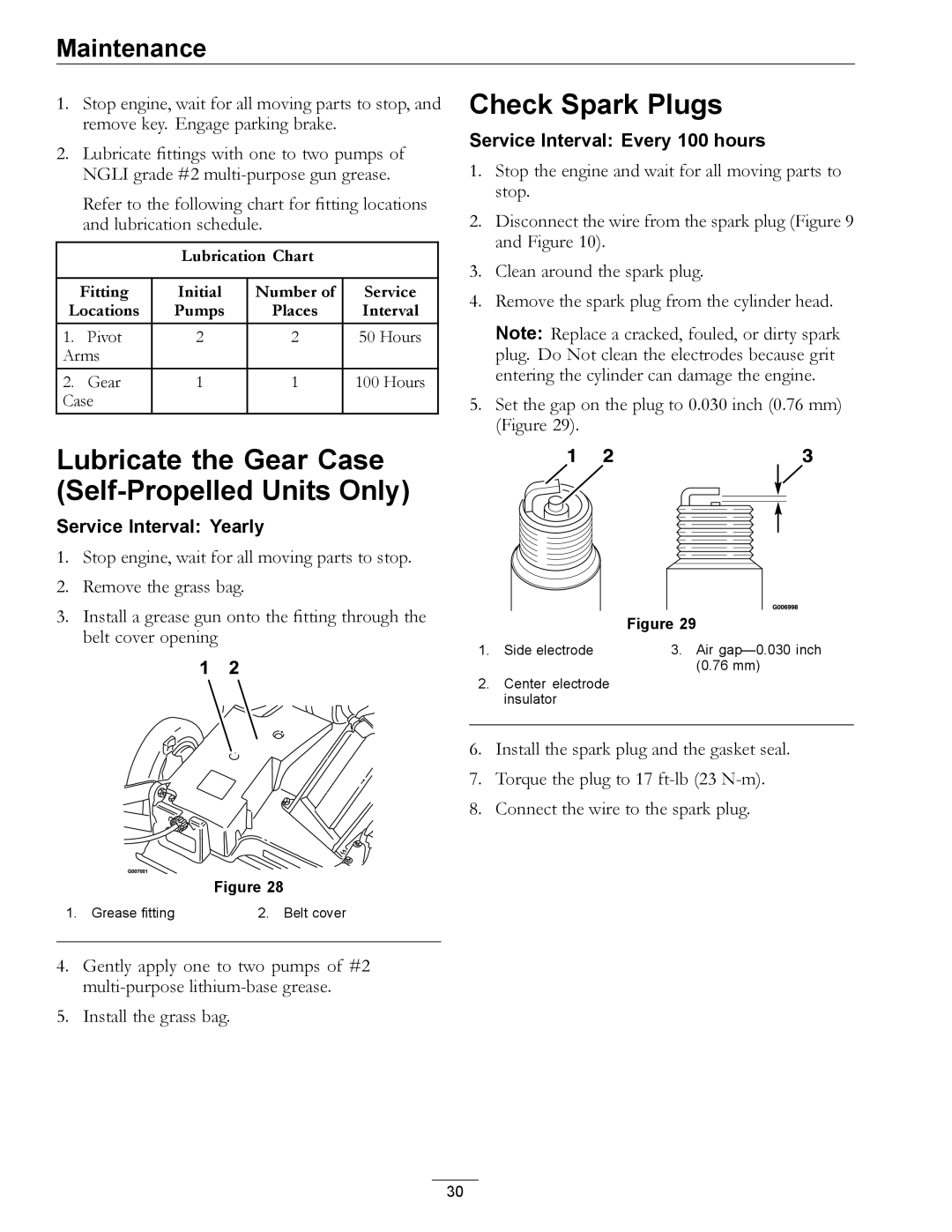

5.Set the gap on the plug to 0.030 inch (0.76 mm) (Figure 29).

| Figure 29 |

1. Side electrode | 3. Air |

| (0.76 mm) |

2.Center electrode insulator

6.Install the spark plug and the gasket seal.

7.Torque the plug to 17

8.Connect the wire to the spark plug.

30