. A complete Parts List is available at www.MillerWelds.com

SECTION 9 − MAINTENANCE AND TROUBLESHOOTING

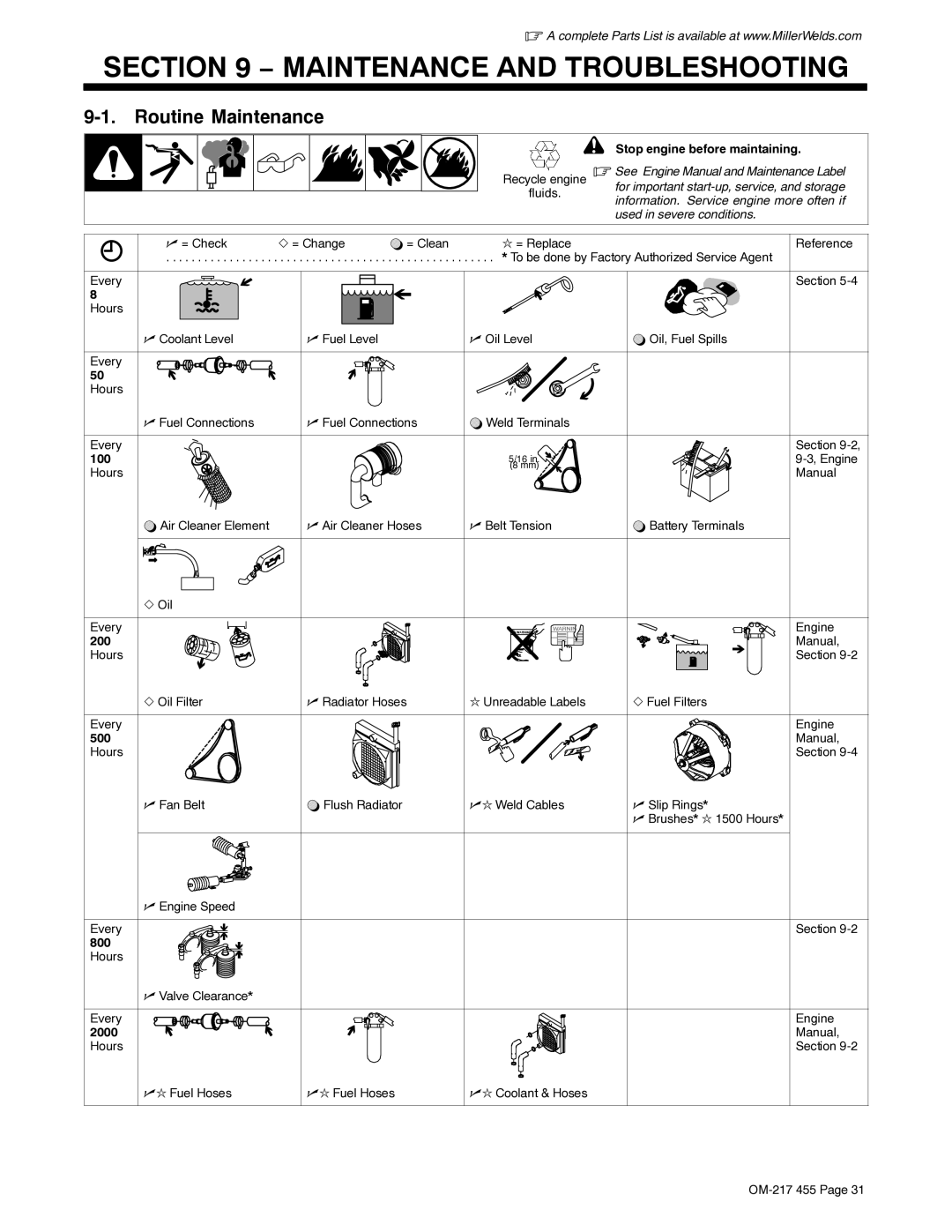

9-1. Routine Maintenance

Recycle engine

fluids.

! Stop engine before maintaining.

! Stop engine before maintaining.

.See Engine Manual and Maintenance Label

for important

n = Check | Z = Change | ~ = Clean | l = Replace | Reference |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * To be done by Factory Authorized Service Agent | ||||

Every |

|

|

| Section |

8 |

|

|

|

|

Hours |

|

|

|

|

n Coolant Level | n Fuel Level |

| n Oil Level | ~ Oil, Fuel Spills |

Every |

|

|

|

|

50 |

|

|

|

|

Hours |

|

|

|

|

n Fuel Connections | n Fuel Connections | ~ Weld Terminals |

| |

Every |

|

|

| Section |

100 |

|

| 5/16 in. | |

Hours |

|

| (8 mm) | Manual |

|

|

| ||

~ Air Cleaner Element | n Air Cleaner Hoses | n Belt Tension | ~ Battery Terminals | |

Z Oil |

|

|

|

|

Every |

|

|

| Engine |

200 |

|

|

| Manual, |

Hours |

|

|

| Section |

Z Oil Filter | n Radiator Hoses | l Unreadable Labels | Z Fuel Filters | |

Every |

|

|

| Engine |

500 |

|

|

| Manual, |

Hours |

|

|

| Section |

n Fan Belt | ~ Flush Radiator | nl Weld Cables | n Slip Rings* | |

|

|

|

| n Brushes* l 1500 Hours* |

n Engine Speed |

|

|

|

|

Every |

|

|

| Section |

800 |

|

|

|

|

Hours |

|

|

|

|

n Valve Clearance* |

|

|

|

|

Every |

|

|

| Engine |

2000 |

|

|

| Manual, |

Hours |

|

|

| Section |

nl Fuel Hoses | nl Fuel Hoses | nl Coolant & Hoses |

| |

|

|

|

| |