. A complete Parts List is available at www.MillerWelds.com

SECTION 8 − OPERATING OPTIONAL BATTERY CHARGER

8-1. Battery Charge Controls

|

|

| ! | Have only qualified persons charge | |

|

|

|

| batteries. |

|

|

|

| ! | Do not use battery charger for jump | |

2 | 1 |

|

| starting. |

|

| NOTICE − D o not use generator power ac re- | ||||

| 4 | 5 | |||

| ceptacles while using optional battery charger. | ||||

|

| ||||

|

|

| Low voltage at receptacles may damage tools | ||

|

|

| and other equipment. |

| |

|

|

| 1 | Charge Voltage Switch |

|

|

|

| Place switch in position matching voltage of | ||

|

|

| battery being charged. |

| |

|

|

| . Before connecting charging cables, place | ||

|

|

|

| Charge Voltage switch in position match- | |

|

|

|

| ing voltage of battery being charged. | |

|

|

| 2 | Battery Charging Switch |

|

|

|

| Place switch in On position to turn on charging | ||

|

|

| current. Place switch in Off position to turn off | ||

|

|

| charging current. |

| |

|

|

| 3 | Weld Process Switch |

|

|

|

| ! | Place switch in Charge position before | |

|

|

|

| connecting charging cables and start- | |

|

|

|

| ing engine. |

|

|

|

| Use switch to select weld or battery charge | ||

|

|

| output (see table in Section |

| |

|

|

| 4 | Coarse Range Switch |

|

|

|

| 5 | Fine Control |

|

|

|

| Use Coarse Range switch and Fine Control to | ||

|

|

| set charge current. |

| |

|

|

| ! | Do not change Coarse Range or Weld | |

| 3 |

|

| Process switch position while welding | |

|

|

| or battery charging. |

| |

|

|

|

|

| |

|

|

| . Charging current automatically stops | ||

|

|

|

| when terminal voltage is 15 to 25 percent | |

|

|

|

| above required battery voltage. | 228 |

|

|

|

|

| |

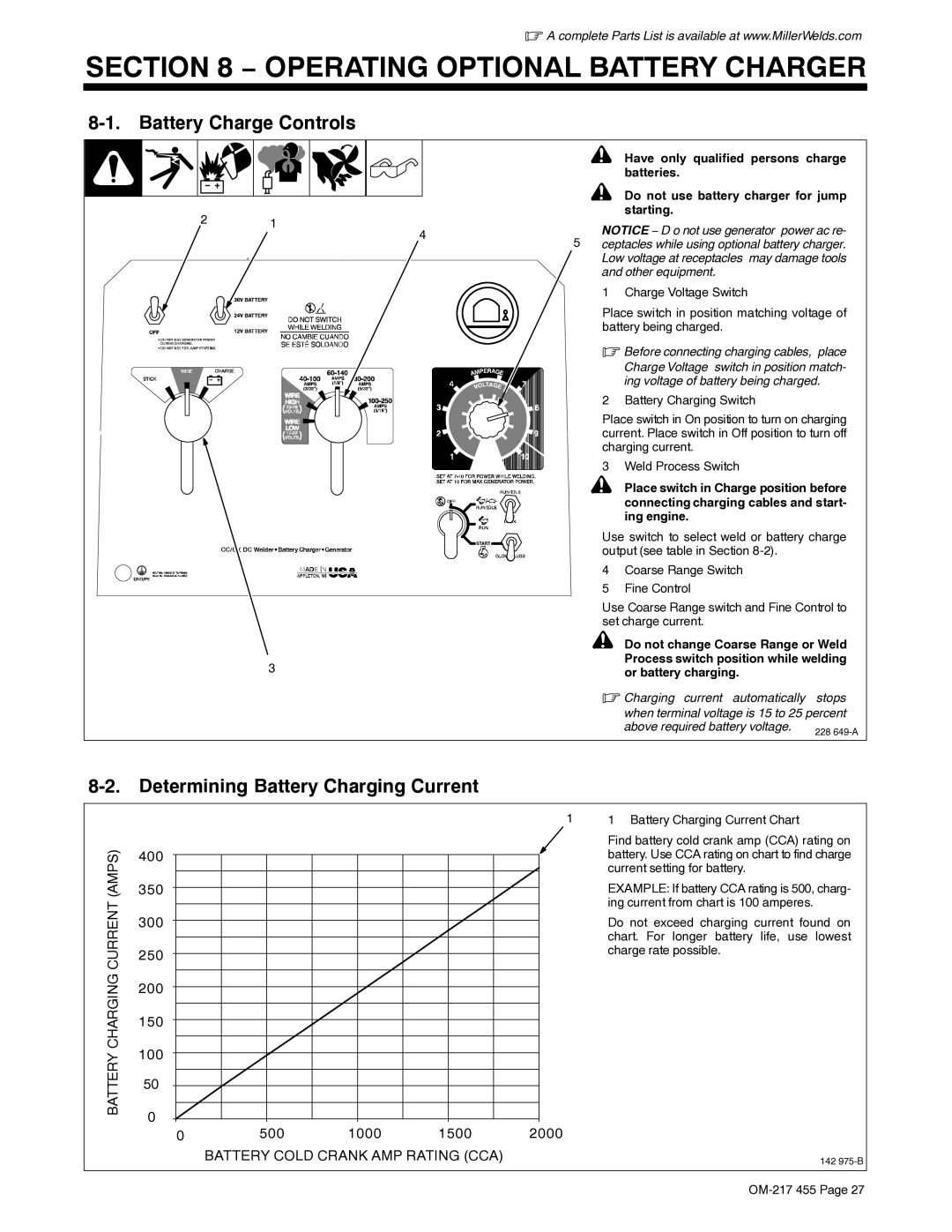

8-2. Determining Battery Charging Current

1

(AMPS) | 400 |

|

|

|

|

350 |

|

|

|

| |

CURRENT | 300 |

|

|

|

|

250 |

|

|

|

| |

|

|

|

|

| |

CHARGING | 200 |

|

|

|

|

150 |

|

|

|

| |

100 |

|

|

|

| |

BATTERY |

|

|

|

| |

50 |

|

|

|

| |

0 |

|

|

|

| |

| 500 | 1000 | 1500 | 2000 | |

| 0 |

BATTERY COLD CRANK AMP RATING (CCA)

1 Battery Charging Current Chart

Find battery cold crank amp (CCA) rating on battery. Use CCA rating on chart to find charge current setting for battery.

EXAMPLE: If battery CCA rating is 500, charg- ing current from chart is 100 amperes.

Do not exceed charging current found on chart. For longer battery life, use lowest charge rate possible.

142