.A complete Parts List is available at www.MillerWelds.com

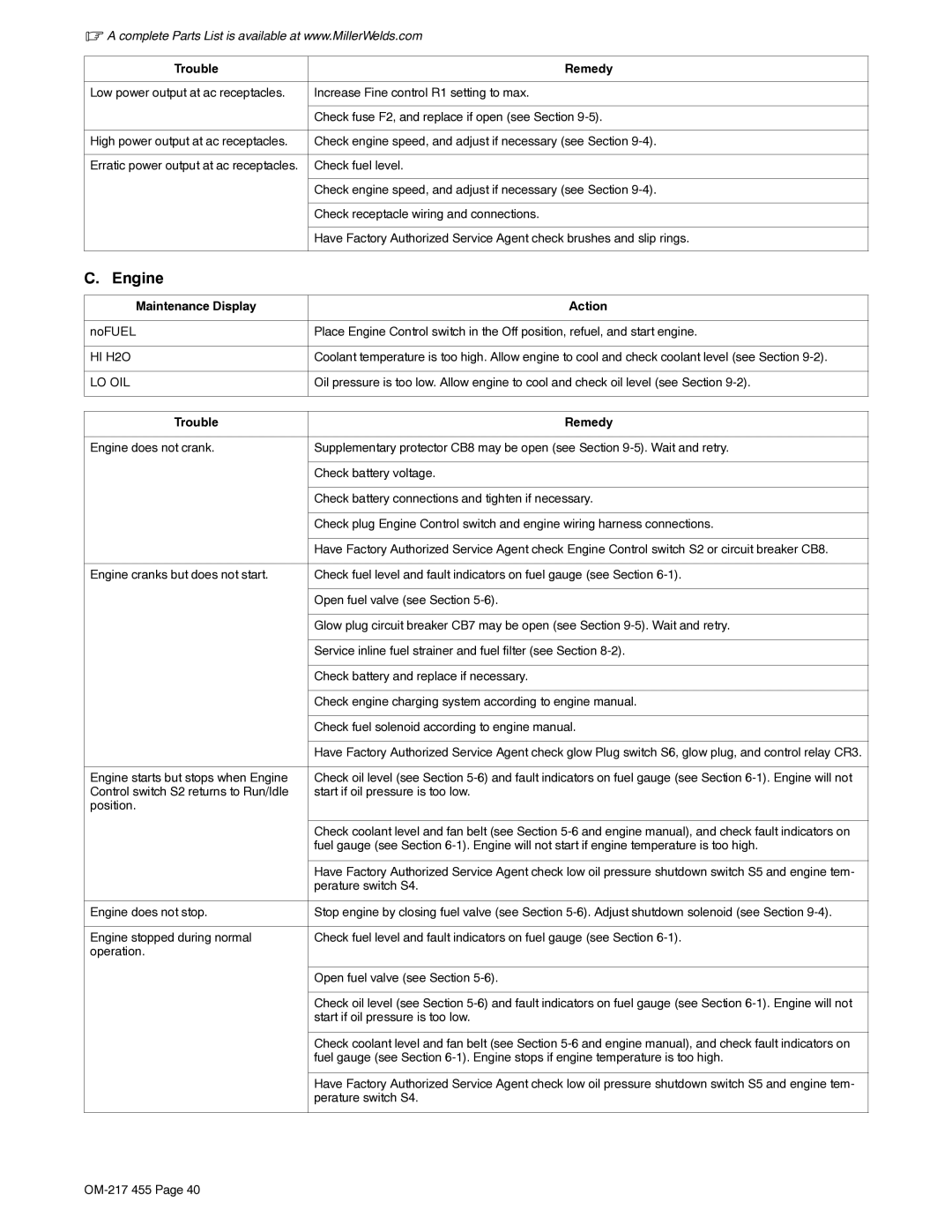

Trouble | Remedy |

|

|

Low power output at ac receptacles. | Increase Fine control R1 setting to max. |

|

|

| Check fuse F2, and replace if open (see Section |

|

|

High power output at ac receptacles. | Check engine speed, and adjust if necessary (see Section |

|

|

Erratic power output at ac receptacles. | Check fuel level. |

|

|

| Check engine speed, and adjust if necessary (see Section |

|

|

| Check receptacle wiring and connections. |

|

|

| Have Factory Authorized Service Agent check brushes and slip rings. |

|

|

C. Engine

Maintenance Display | Action |

|

|

noFUEL | Place Engine Control switch in the Off position, refuel, and start engine. |

|

|

HI H2O | Coolant temperature is too high. Allow engine to cool and check coolant level (see Section |

|

|

LO OIL | Oil pressure is too low. Allow engine to cool and check oil level (see Section |

|

|

Trouble | Remedy |

|

|

Engine does not crank. | Supplementary protector CB8 may be open (see Section |

|

|

| Check battery voltage. |

|

|

| Check battery connections and tighten if necessary. |

|

|

| Check plug Engine Control switch and engine wiring harness connections. |

|

|

| Have Factory Authorized Service Agent check Engine Control switch S2 or circuit breaker CB8. |

|

|

Engine cranks but does not start. | Check fuel level and fault indicators on fuel gauge (see Section |

|

|

| Open fuel valve (see Section |

|

|

| Glow plug circuit breaker CB7 may be open (see Section |

|

|

| Service inline fuel strainer and fuel filter (see Section |

|

|

| Check battery and replace if necessary. |

|

|

| Check engine charging system according to engine manual. |

|

|

| Check fuel solenoid according to engine manual. |

|

|

| Have Factory Authorized Service Agent check glow Plug switch S6, glow plug, and control relay CR3. |

|

|

Engine starts but stops when Engine | Check oil level (see Section |

Control switch S2 returns to Run/Idle | start if oil pressure is too low. |

position. |

|

|

|

| Check coolant level and fan belt (see Section |

| fuel gauge (see Section |

|

|

| Have Factory Authorized Service Agent check low oil pressure shutdown switch S5 and engine tem- |

| perature switch S4. |

|

|

Engine does not stop. | Stop engine by closing fuel valve (see Section |

|

|

Engine stopped during normal | Check fuel level and fault indicators on fuel gauge (see Section |

operation. |

|

|

|

| Open fuel valve (see Section |

|

|

| Check oil level (see Section |

| start if oil pressure is too low. |

|

|

| Check coolant level and fan belt (see Section |

| fuel gauge (see Section |

|

|

| Have Factory Authorized Service Agent check low oil pressure shutdown switch S5 and engine tem- |

| perature switch S4. |

|

|