.A complete Parts List is available at www.MillerWelds.com

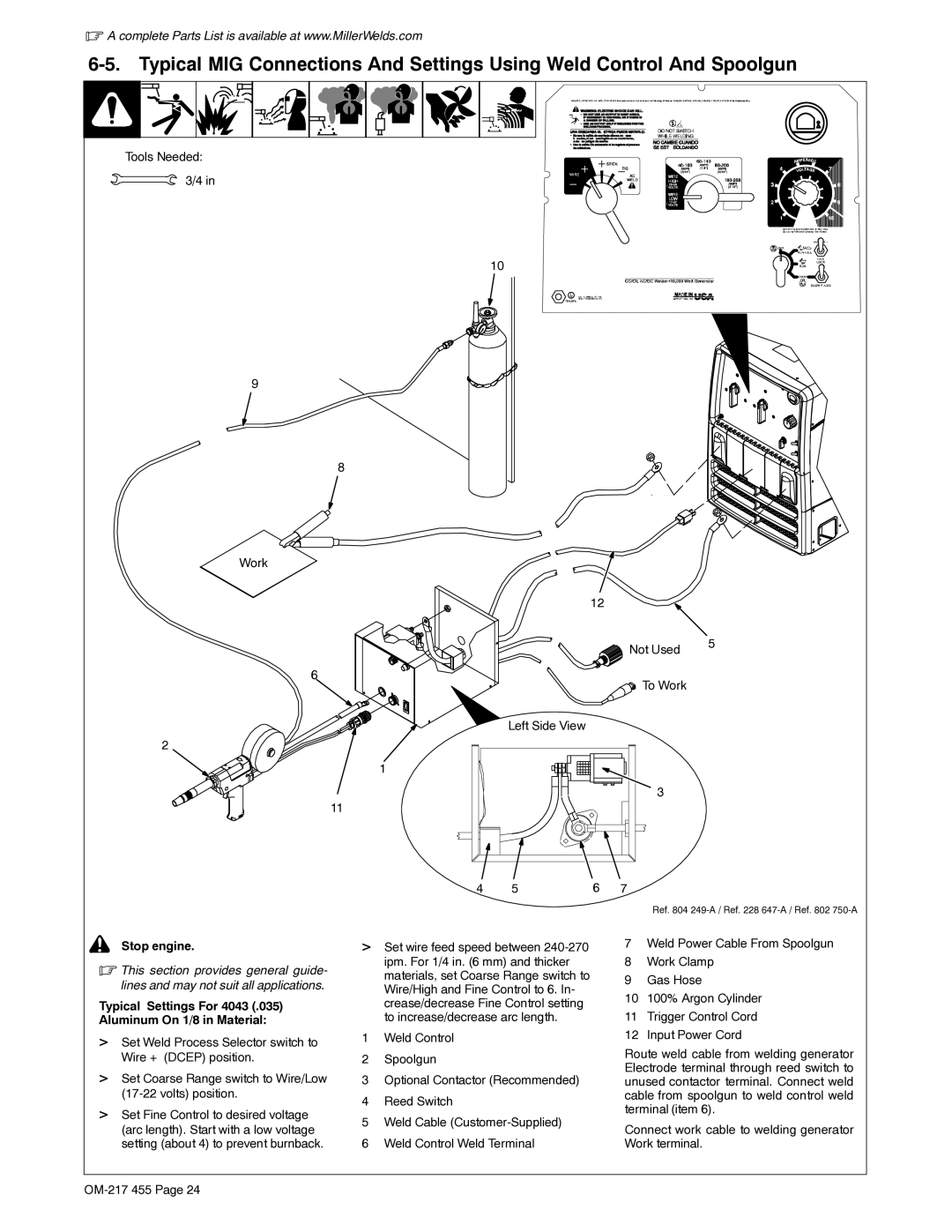

Tools Needed: 3/4 in

9

8

Work

6

2

10

12

Not Used | 5 |

| |

To Work |

|

Left Side View

11

! Stop engine.

! Stop engine.

.This section provides general guide- lines and may not suit all applications.

Typical Settings For 4043 (.035) Aluminum On 1/8 in Material:

>Set Weld Process Selector switch to Wire + (DCEP) position.

>Set Coarse Range switch to Wire/Low

>Set Fine Control to desired voltage (arc length). Start with a low voltage setting (about 4) to prevent burnback.

1

4 | 5 | 6 |

>Set wire feed speed between

1Weld Control

2Spoolgun

3Optional Contactor (Recommended)

4Reed Switch

5Weld Cable

6Weld Control Weld Terminal

3

7

Ref. 804

7Weld Power Cable From Spoolgun

8Work Clamp

9Gas Hose

10100% Argon Cylinder

11Trigger Control Cord

12Input Power Cord

Route weld cable from welding generator Electrode terminal through reed switch to unused contactor terminal. Connect weld cable from spoolgun to weld control weld terminal (item 6).

Connect work cable to welding generator Work terminal.