.A complete Parts List is available at www.MillerWelds.com

SECTION 6 − OPERATING THE WELDING GENERATOR

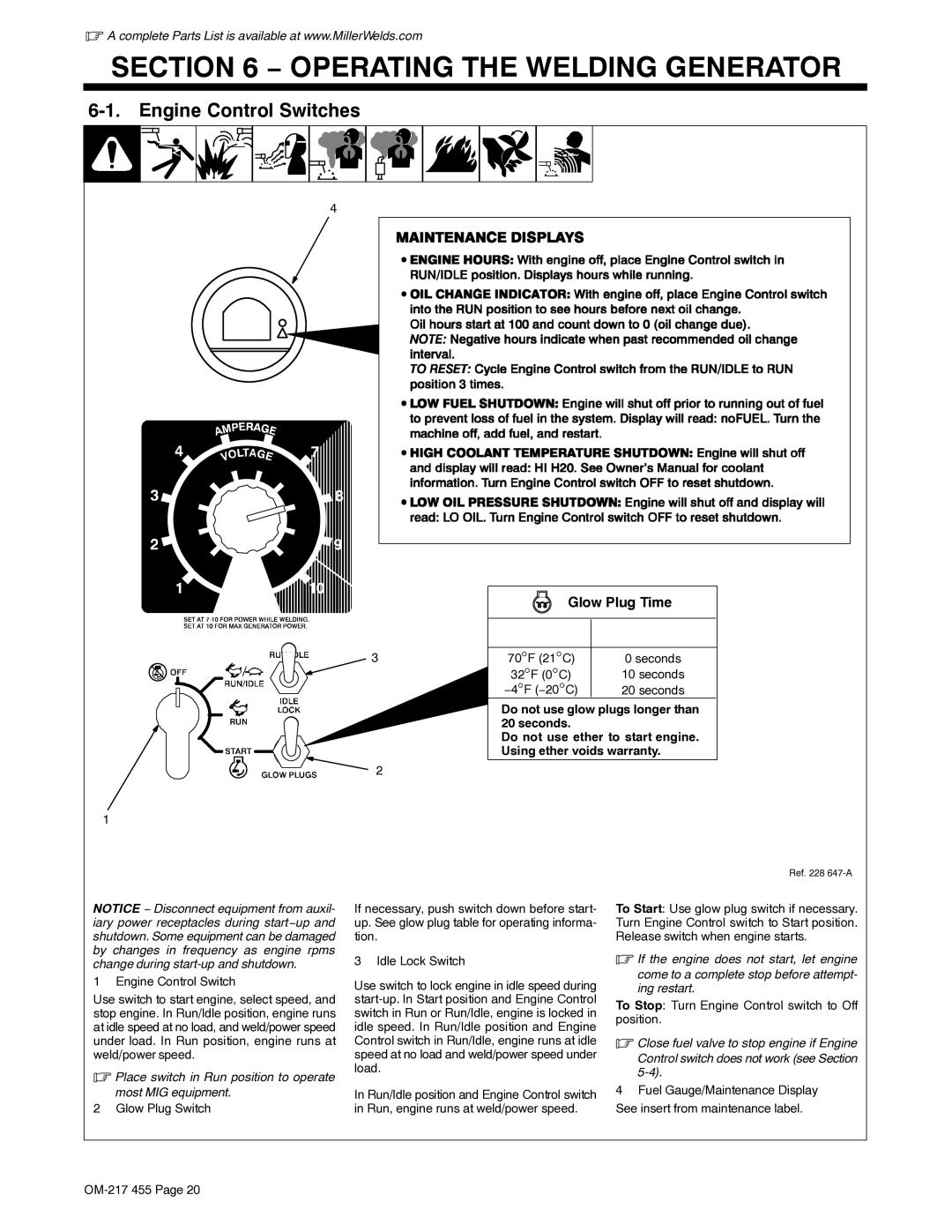

6-1. Engine Control Switches

4

3

2

Glow Plug Time

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| t | |

|

|

|

|

|

| |||

|

|

| 70°F (21°C) | 0 seconds | ||||

|

|

| 32°F (0°C) |

|

| 10 seconds | ||

|

| −4°F (−20°C) |

|

|

| 20 seconds | ||

Do not use glow plugs longer than 20 seconds.

Do not use ether to start engine. Using ether voids warranty.

1

Ref. 228

NOTICE − Disconnect equipment from auxil- iary power receptacles during start−up and shutdown. Some equipment can be damaged by changes in frequency as engine rpms change during

1 Engine Control Switch

Use switch to start engine, select speed, and stop engine. In Run/Idle position, engine runs at idle speed at no load, and weld/power speed under load. In Run position, engine runs at weld/power speed.

.Place switch in Run position to operate most MIG equipment.

2 Glow Plug Switch

If necessary, push switch down before start- up. See glow plug table for operating informa- tion.

3 Idle Lock Switch

Use switch to lock engine in idle speed during

In Run/Idle position and Engine Control switch in Run, engine runs at weld/power speed.

To Start: Use glow plug switch if necessary. Turn Engine Control switch to Start position. Release switch when engine starts.

.If the engine does not start, let engine

come to a complete stop before attempt- ing restart.

To Stop: Turn Engine Control switch to Off position.

.Close fuel valve to stop engine if Engine

Control switch does not work (see Section

4Fuel Gauge/Maintenance Display See insert from maintenance label.