.A complete Parts List is available at www.MillerWelds.com

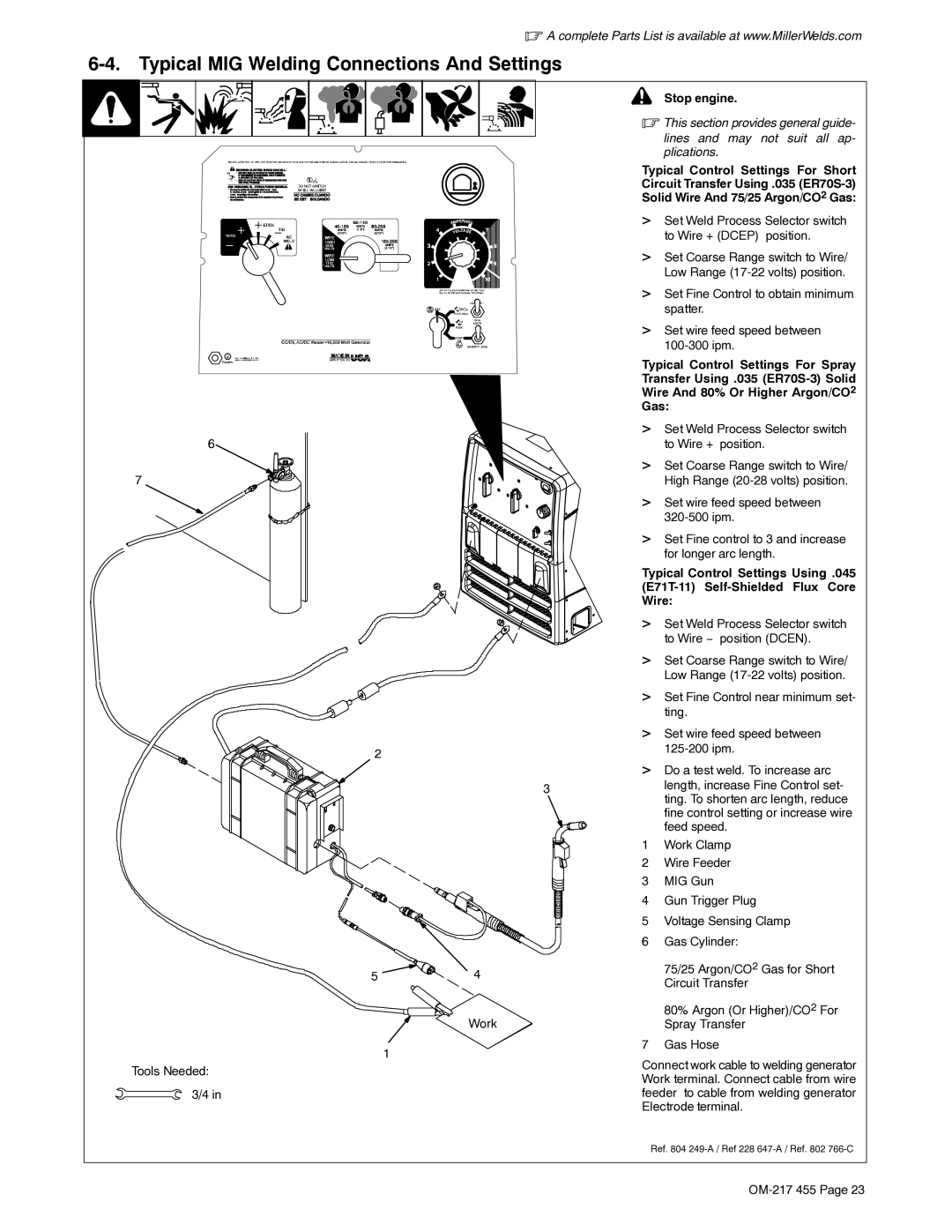

6-4. Typical MIG Welding Connections And Settings

6

7

2

3

5 ![]()

![]() 4

4

Work

1

Tools Needed: 3/4 in

! Stop engine.

! Stop engine.

.This section provides general guide-

lines and may not suit all ap- plications.

Typical Control Settings For Short Circuit Transfer Using .035

>Set Weld Process Selector switch to Wire + (DCEP) position.

>Set Coarse Range switch to Wire/ Low Range

>Set Fine Control to obtain minimum spatter.

>Set wire feed speed between

Typical Control Settings For Spray

Transfer Using .035

Wire And 80% Or Higher Argon/CO2

Gas:

>Set Weld Process Selector switch to Wire + position.

>Set Coarse Range switch to Wire/ High Range

>Set wire feed speed between

>Set Fine control to 3 and increase for longer arc length.

Typical Control Settings Using .045

Wire:

>Set Weld Process Selector switch to Wire − position (DCEN).

>Set Coarse Range switch to Wire/ Low Range

>Set Fine Control near minimum set- ting.

>Set wire feed speed between

>Do a test weld. To increase arc length, increase Fine Control set- ting. To shorten arc length, reduce fine control setting or increase wire feed speed.

1Work Clamp

2Wire Feeder

3MIG Gun

4Gun Trigger Plug

5Voltage Sensing Clamp

6Gas Cylinder:

75/25 Argon/CO2 Gas for Short Circuit Transfer

80% Argon (Or Higher)/CO2 For Spray Transfer

7Gas Hose

Connect work cable to welding generator Work terminal. Connect cable from wire feeder to cable from welding generator Electrode terminal.

Ref. 804