Maintenance

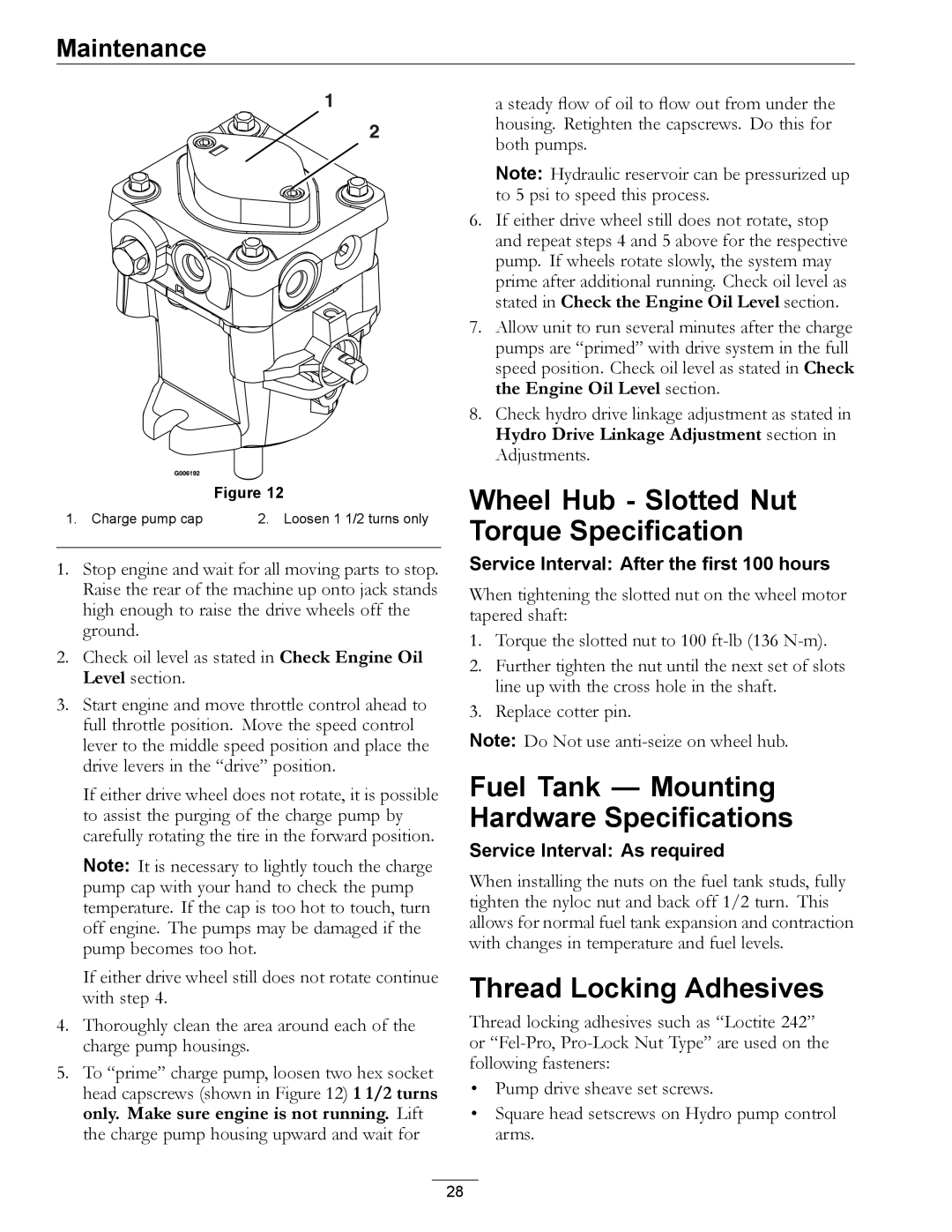

Figure 12

1. Charge pump cap | 2. Loosen 1 1/2 turns only |

1.Stop engine and wait for all moving parts to stop. Raise the rear of the machine up onto jack stands high enough to raise the drive wheels off the ground.

2.Check oil level as stated in Check Engine Oil Level section.

3.Start engine and move throttle control ahead to full throttle position. Move the speed control lever to the middle speed position and place the drive levers in the “drive” position.

If either drive wheel does not rotate, it is possible to assist the purging of the charge pump by carefully rotating the tire in the forward position.

Note: It is necessary to lightly touch the charge pump cap with your hand to check the pump temperature. If the cap is too hot to touch, turn off engine. The pumps may be damaged if the pump becomes too hot.

If either drive wheel still does not rotate continue with step 4.

4.Thoroughly clean the area around each of the charge pump housings.

5.To “prime” charge pump, loosen two hex socket head capscrews (shown in Figure 12) 1 1/2 turns only. Make sure engine is not running. Lift the charge pump housing upward and wait for

a steady flow of oil to flow out from under the housing. Retighten the capscrews. Do this for both pumps.

Note: Hydraulic reservoir can be pressurized up to 5 psi to speed this process.

6.If either drive wheel still does not rotate, stop and repeat steps 4 and 5 above for the respective pump. If wheels rotate slowly, the system may prime after additional running. Check oil level as stated in Check the Engine Oil Level section.

7.Allow unit to run several minutes after the charge pumps are “primed” with drive system in the full speed position. Check oil level as stated in Check the Engine Oil Level section.

8.Check hydro drive linkage adjustment as stated in Hydro Drive Linkage Adjustment section in Adjustments.

Wheel Hub - Slotted Nut Torque Specification

Service Interval: After the first 100 hours

When tightening the slotted nut on the wheel motor tapered shaft:

1.Torque the slotted nut to 100

2.Further tighten the nut until the next set of slots line up with the cross hole in the shaft.

3.Replace cotter pin.

Note: Do Not use

Fuel Tank — Mounting Hardware Specifications

Service Interval: As required

When installing the nuts on the fuel tank studs, fully tighten the nyloc nut and back off 1/2 turn. This allows for normal fuel tank expansion and contraction with changes in temperature and fuel levels.

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242” or

•Pump drive sheave set screws.

•Square head setscrews on Hydro pump control arms.

28