Operation

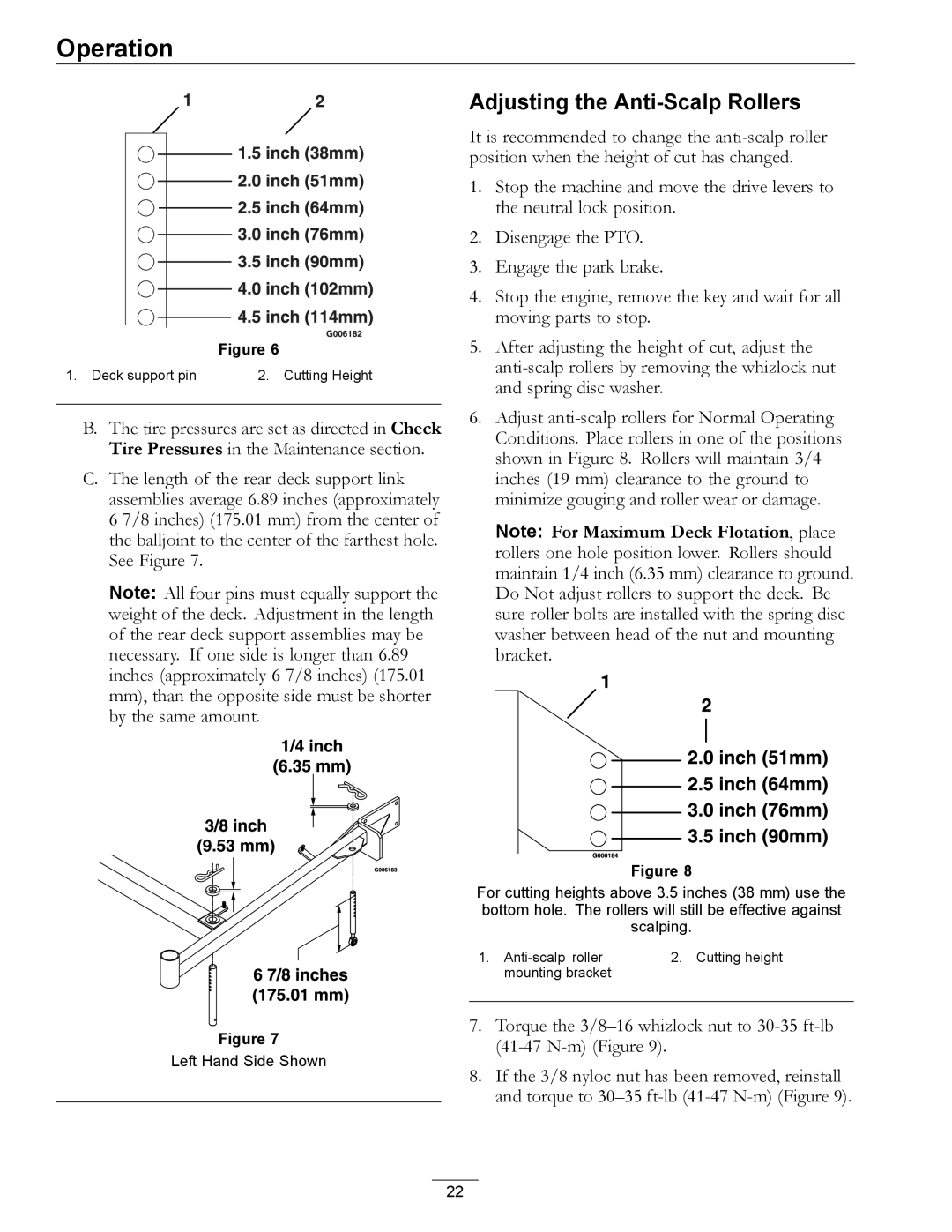

Figure 6

1. Deck support pin | 2. Cutting Height |

B.The tire pressures are set as directed in Check Tire Pressures in the Maintenance section.

C.The length of the rear deck support link assemblies average 6.89 inches (approximately 6 7/8 inches) (175.01 mm) from the center of the balljoint to the center of the farthest hole. See Figure 7.

Note: All four pins must equally support the weight of the deck. Adjustment in the length of the rear deck support assemblies may be necessary. If one side is longer than 6.89 inches (approximately 6 7/8 inches) (175.01 mm), than the opposite side must be shorter by the same amount.

Adjusting the Anti-Scalp Rollers

It is recommended to change the

1.Stop the machine and move the drive levers to the neutral lock position.

2.Disengage the PTO.

3.Engage the park brake.

4.Stop the engine, remove the key and wait for all moving parts to stop.

5.After adjusting the height of cut, adjust the

6.Adjust

Note: For Maximum Deck Flotation, place rollers one hole position lower. Rollers should maintain 1/4 inch (6.35 mm) clearance to ground. Do Not adjust rollers to support the deck. Be sure roller bolts are installed with the spring disc washer between head of the nut and mounting bracket.

Figure 7

Left Hand Side Shown

Figure 8

For cutting heights above 3.5 inches (38 mm) use the bottom hole. The rollers will still be effective against scalping.

1. | 2. Cutting height |

mounting bracket |

|

7.Torque the

8.If the 3/8 nyloc nut has been removed, reinstall and torque to

22