Maintenance

Inspect PTO Clutching Belt Tension

Service Interval: After the first 2 hours Check every 2 hours for the first 8 hours of operation.

Every 40 hours thereafter.

1.Stop engine and wait for all moving parts to stop.

2.Engage PTO lever.

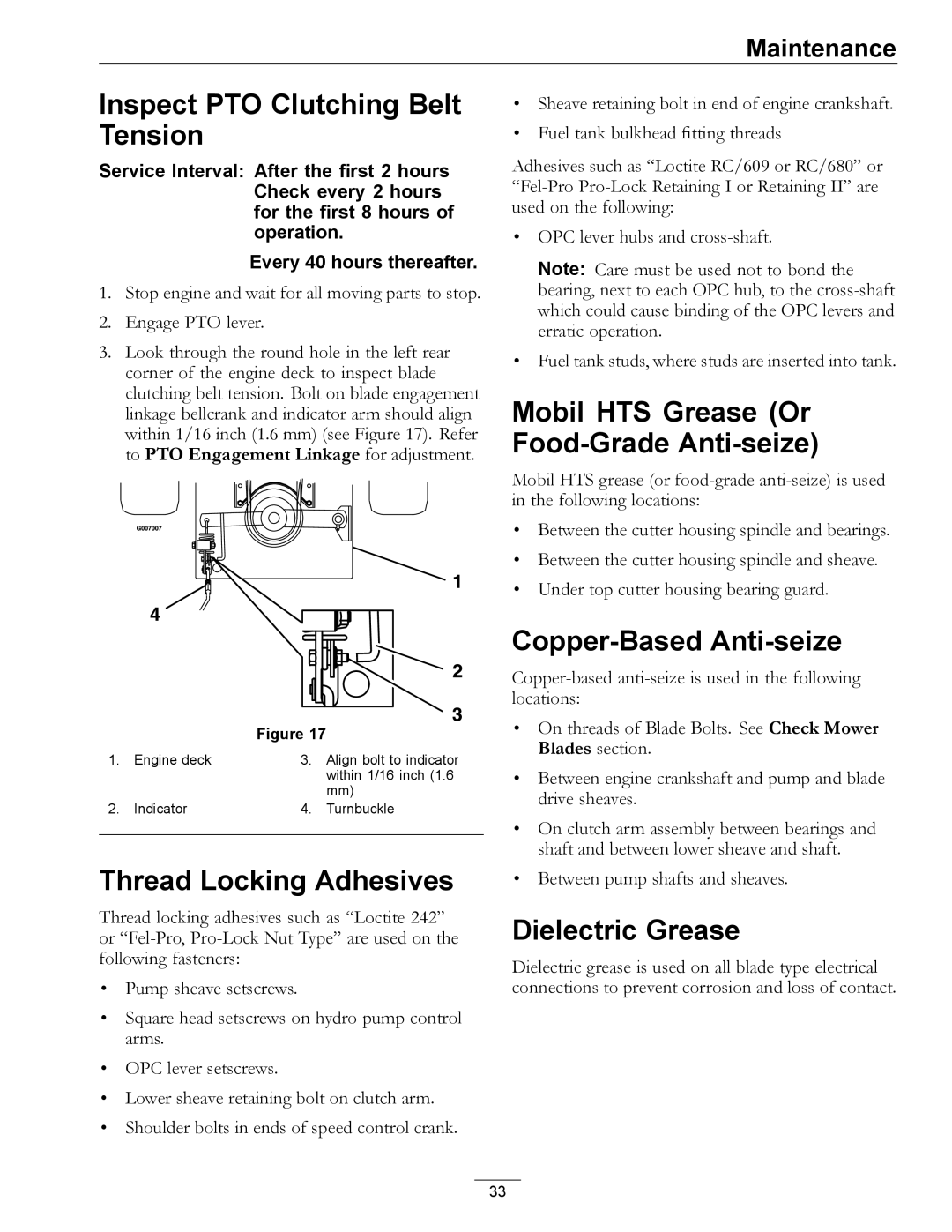

3.Look through the round hole in the left rear corner of the engine deck to inspect blade clutching belt tension. Bolt on blade engagement linkage bellcrank and indicator arm should align within 1/16 inch (1.6 mm) (see Figure 17). Refer to PTO Engagement Linkage for adjustment.

Figure 17

1. | Engine deck | 3. | Align bolt to indicator |

|

|

| within 1/16 inch (1.6 |

|

|

| mm) |

2. | Indicator | 4. | Turnbuckle |

|

|

|

|

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242” or

•Pump sheave setscrews.

•Square head setscrews on hydro pump control arms.

•OPC lever setscrews.

•Lower sheave retaining bolt on clutch arm.

•Shoulder bolts in ends of speed control crank.

•Sheave retaining bolt in end of engine crankshaft.

•Fuel tank bulkhead fitting threads

Adhesives such as “Loctite RC/609 or RC/680” or

•OPC lever hubs and

Note: Care must be used not to bond the bearing, next to each OPC hub, to the

•Fuel tank studs, where studs are inserted into tank.

Mobil HTS Grease (Or Food-Grade Anti-seize)

Mobil HTS grease (or

•Between the cutter housing spindle and bearings.

•Between the cutter housing spindle and sheave.

•Under top cutter housing bearing guard.

Copper-Based Anti-seize

•On threads of Blade Bolts. See Check Mower Blades section.

•Between engine crankshaft and pump and blade drive sheaves.

•On clutch arm assembly between bearings and shaft and between lower sheave and shaft.

•Between pump shafts and sheaves.

Dielectric Grease

Dielectric grease is used on all blade type electrical connections to prevent corrosion and loss of contact.

33