SB-125Ci, SB-125i specifications

The Fellowes SB-125i and SB-125Ci shredder models are designed to offer comprehensive document security and convenience for both personal and office use. These shredders combine advanced technology with user-friendly features, making them suitable for a variety of shredding needs.One of the standout features of both models is their ability to shred various types of materials efficiently. The SB-125i and SB-125Ci can handle not only paper but also credit cards, staples, and small paper clips, enabling users to dispose of sensitive documents without the hassle of removing these materials beforehand. This efficiency saves time and promotes a streamlined shredding process.

In terms of security, the SB-125i and SB-125Ci provide high-security shredding capabilities. They offer cross-cut shredding, which converts documents into small, unreadable particles. This feature ensures that sensitive information is safely destroyed, making these machines ideal for businesses and individuals handling confidential data. The security level of these shredders meets P-4 standards, which is sufficient for most office environments and personal use.

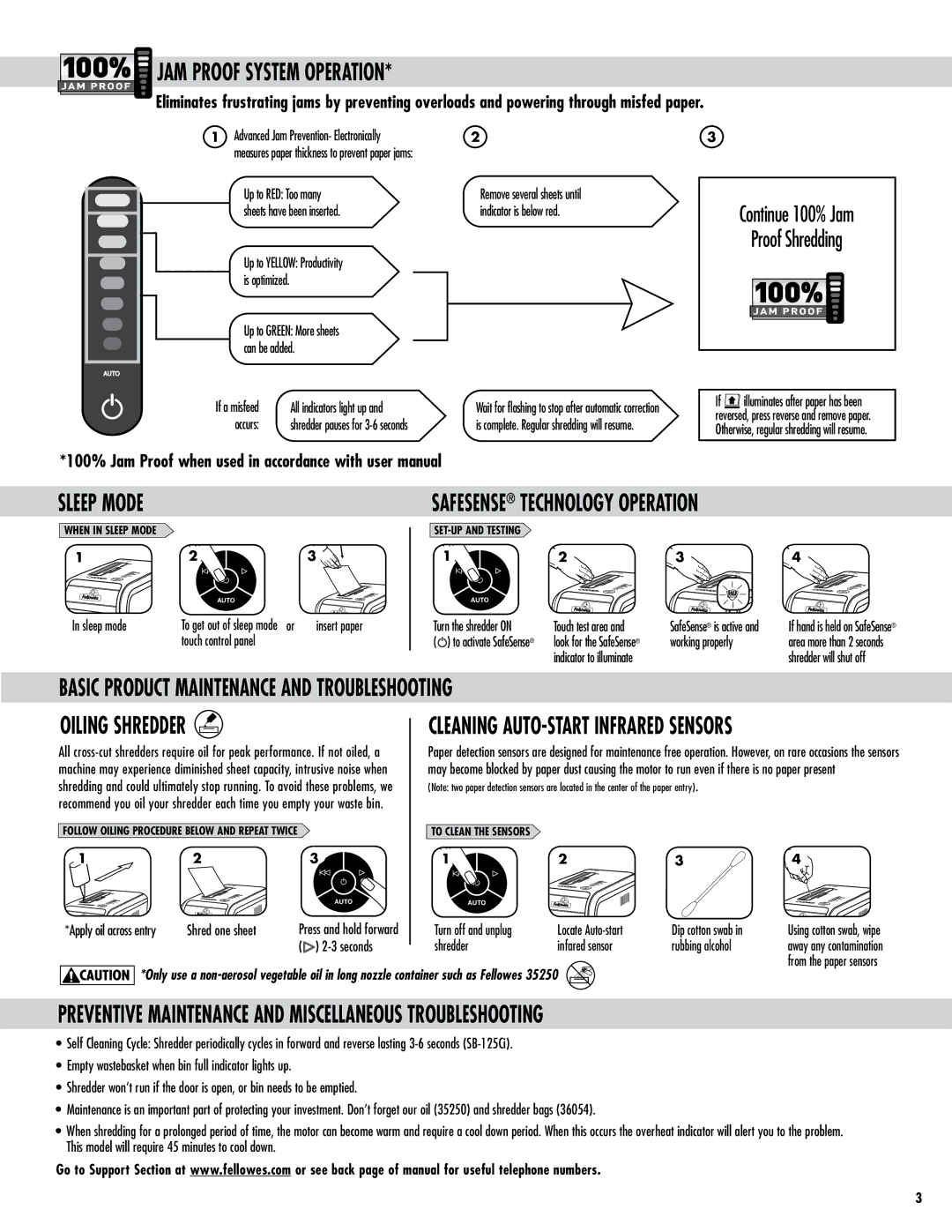

Both models are equipped with Fellowes' SafeSense technology, enhancing user safety dramatically. This feature automatically shuts down the shredder if hands come too close to the feed opening. This thoughtful design helps prevent accidents, particularly in environments where children or pets may be present.

Another notable characteristic is the large capacity of the waste bin. The SB-125i and SB-125Ci come with a substantial waste bin that minimizes the frequency of emptying. The easy lift-off head design allows for quick and hassle-free waste disposal, further enhancing the user experience.

The quiet operation of these shredders makes them perfect for shared workspaces. Users can shred documents without causing excessive noise disturbances, promoting a more comfortable working environment.

Furthermore, both models feature a user-friendly control panel, allowing for convenient operation. The forward and reverse functions help clear paper jams efficiently, while the energy-saving mode ensures that the shredder conserves power during periods of inactivity.

In summary, the Fellowes SB-125i and SB-125Ci shredders stand out with their robust shredding capabilities, security features, and user-friendly design. Their advanced technologies provide a reliable solution for managing sensitive information while maintaining safety and convenience. Whether for home or office use, these shredders present a worthy investment in document protection.