ZMT Owner’s Manual

7MACHINE MAINTENANCE

All maintenance, cleaning and repair operations must be carried out with the shredder firmly lowered to the ground and detached from the tractor, or with disconnected PTO, engine off and ignition key out.

After the first 2 hours of operation from new (or after fitting new belts), check belt tension.

Check regularly after every 8 hours’ operation:

•Tighten bolts and nuts.

•Check wear and condition of flails.

•Check that the protection flaps may be blocked or damaged by the presence of mud and stones or residuals of mown material. Should this be the case stop the tractor immediately, clean and repair the protection flaps as necessary. Adjustmets or maintenance work should only be carried out when the machine is stopped and the tractor engine is switched off.

•Check belt stretch and condition.

•Visually check the frame and arms to detect possible damage caused by earlier work.

•Check gearbox and extension lubricating levels.

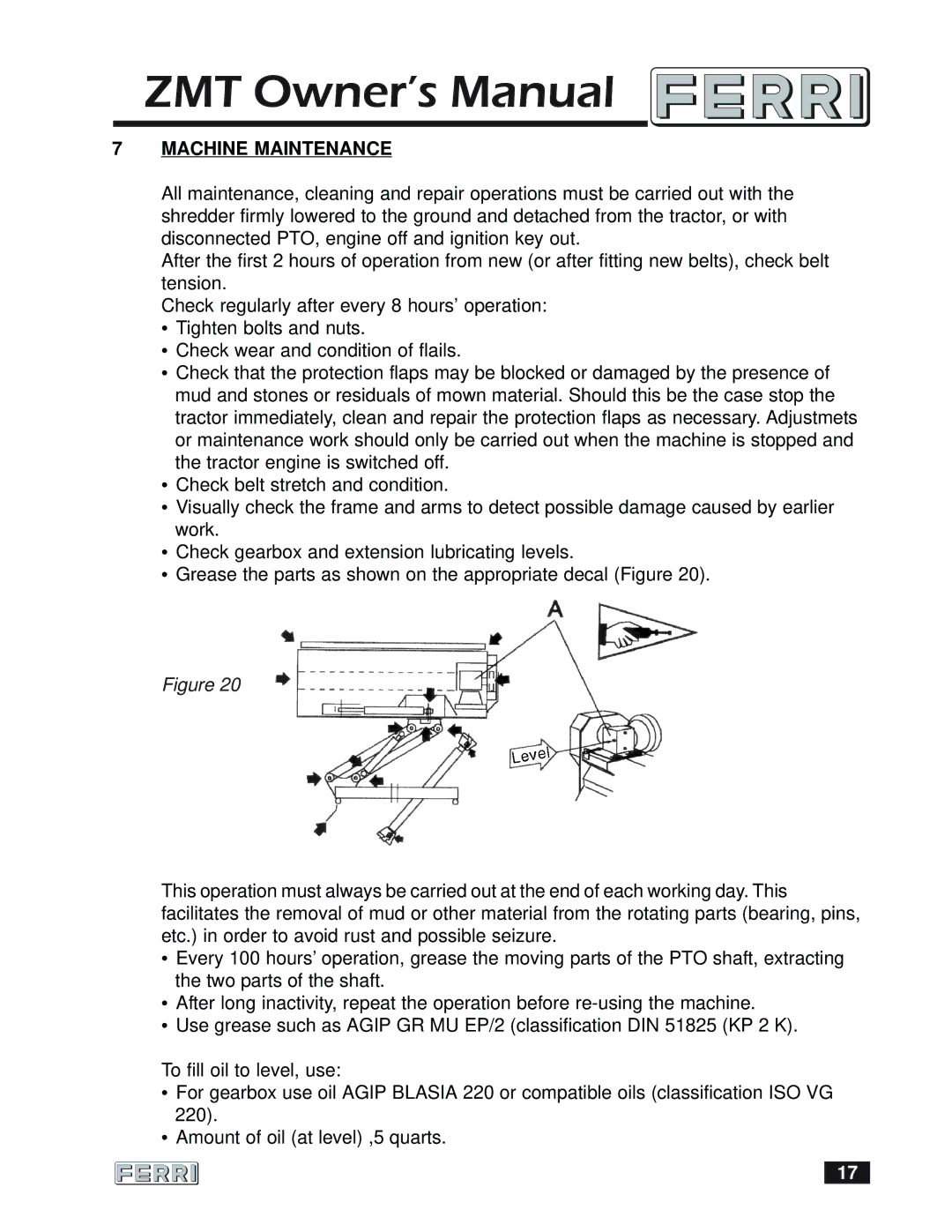

•Grease the parts as shown on the appropriate decal (Figure 20).

Figure 20

This operation must always be carried out at the end of each working day. This facilitates the removal of mud or other material from the rotating parts (bearing, pins, etc.) in order to avoid rust and possible seizure.

•Every 100 hours’ operation, grease the moving parts of the PTO shaft, extracting the two parts of the shaft.

•After long inactivity, repeat the operation before

•Use grease such as AGIP GR MU EP/2 (classification DIN 51825 (KP 2 K).

To fill oil to level, use:

•For gearbox use oil AGIP BLASIA 220 or compatible oils (classification ISO VG 220).

•Amount of oil (at level) ,5 quarts.

17