70

3 | 4 |

5 | 6 |

7 | 8 |

|

| 10 | |

| assemblies, bandsaw the waste from the | |

| underside of the feet and sand all the | |

| parts (Fig. 4) to | |

| sandpaper to the 22.5° wedge offcuts to | |

| prevent slippage when the clamps are | |

| tightened. | |

9 | The glueup is done in several stages, | |

using a | ||

| ||

| consistency and a hardener that will | |

grain of the back rails, seat rails, and | allow plenty of time for assembly. It’s | |

stretcher are all centered in their end | easy to clean up after using epoxy if | |

faces. | you spread carnauba wax in the areas | |

Gluing the side assemblies | that you expect | |

The epoxy won’t stick to it and the wax | ||

Before you start to glue up the side | can be removed with mineral spirits |

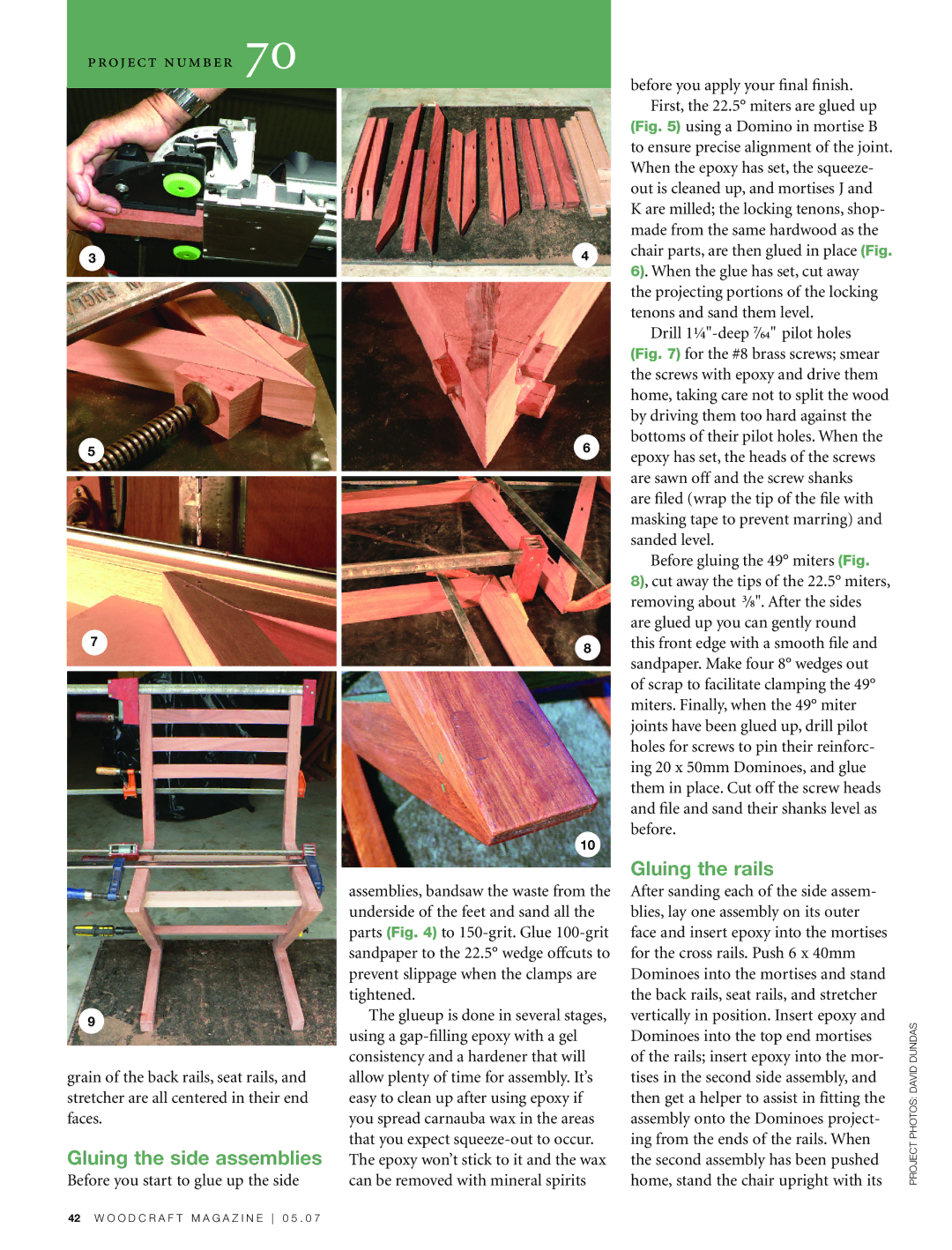

before you apply your final finish. First, the 22.5° miters are glued up

(Fig. 5) using a Domino in mortise B to ensure precise alignment of the joint. When the epoxy has set, the squeeze- out is cleaned up, and mortises J and K are milled; the locking tenons, shop- made from the same hardwood as the chair parts, are then glued in place (Fig. 6). When the glue has set, cut away the projecting portions of the locking tenons and sand them level.

Drill 1¼"-deep 7/64" pilot holes (Fig. 7) for the #8 brass screws; smear the screws with epoxy and drive them home, taking care not to split the wood by driving them too hard against the bottoms of their pilot holes. When the epoxy has set, the heads of the screws are sawn off and the screw shanks

are filed (wrap the tip of the file with masking tape to prevent marring) and sanded level.

Before gluing the 49° miters (Fig.

8), cut away the tips of the 22.5° miters, removing about 3/8". After the sides are glued up you can gently round this front edge with a smooth file and sandpaper. Make four 8° wedges out of scrap to facilitate clamping the 49° miters. Finally, when the 49° miter joints have been glued up, drill pilot holes for screws to pin their reinforc- ing 20 x 50mm Dominoes, and glue them in place. Cut off the screw heads and file and sand their shanks level as before.

Gluing the rails

After sanding each of the side assem- blies, lay one assembly on its outer face and insert epoxy into the mortises for the cross rails. Push 6 x 40mm Dominoes into the mortises and stand the back rails, seat rails, and stretcher vertically in position. Insert epoxy and Dominoes into the top end mortises of the rails; insert epoxy into the mor- tises in the second side assembly, and then get a helper to assist in fitting the assembly onto the Dominoes project- ing from the ends of the rails. When the second assembly has been pushed home, stand the chair upright with its

project photos: david dundas

42 w o o d c r a f t m a g a z i n e 0 5 . 0 7