Irmount R

Table of Contents

Introduction

Advantages of Firestone Airstroke Actuators

Advantages of Firestone Airmount Isolators

AIR Spring

Bellows Construction

Convoluted AIR Springs

END Closure Options

Reversible Sleeve AIR Springs

16 UNC To Air Supply Blind Nut Deep

Tightening Torque On the blind nut 15 to 20 ft.-lbs

UNC Thread Firestone

Attach the air spring, a Stud Adapter is available from

Steel Bead Rings

Nuts and Lockwashers are included with

Large Parts with Aluminum Bead Rings

Installation

Material

Standard Bolt Length

16-24 UNF

Large Convoluted AIR Springs

9mm

HOW to USE Static Data Chart

Airstroke Actuation

752 180

349

Airmount Isolation

Internal Rubber Bumpers

Temperature

Media

Pressure

Contaminates

Airstroke Actuation

Selection

Down and UP Stops

Return

Horizontal Misalignment

Design Envelope

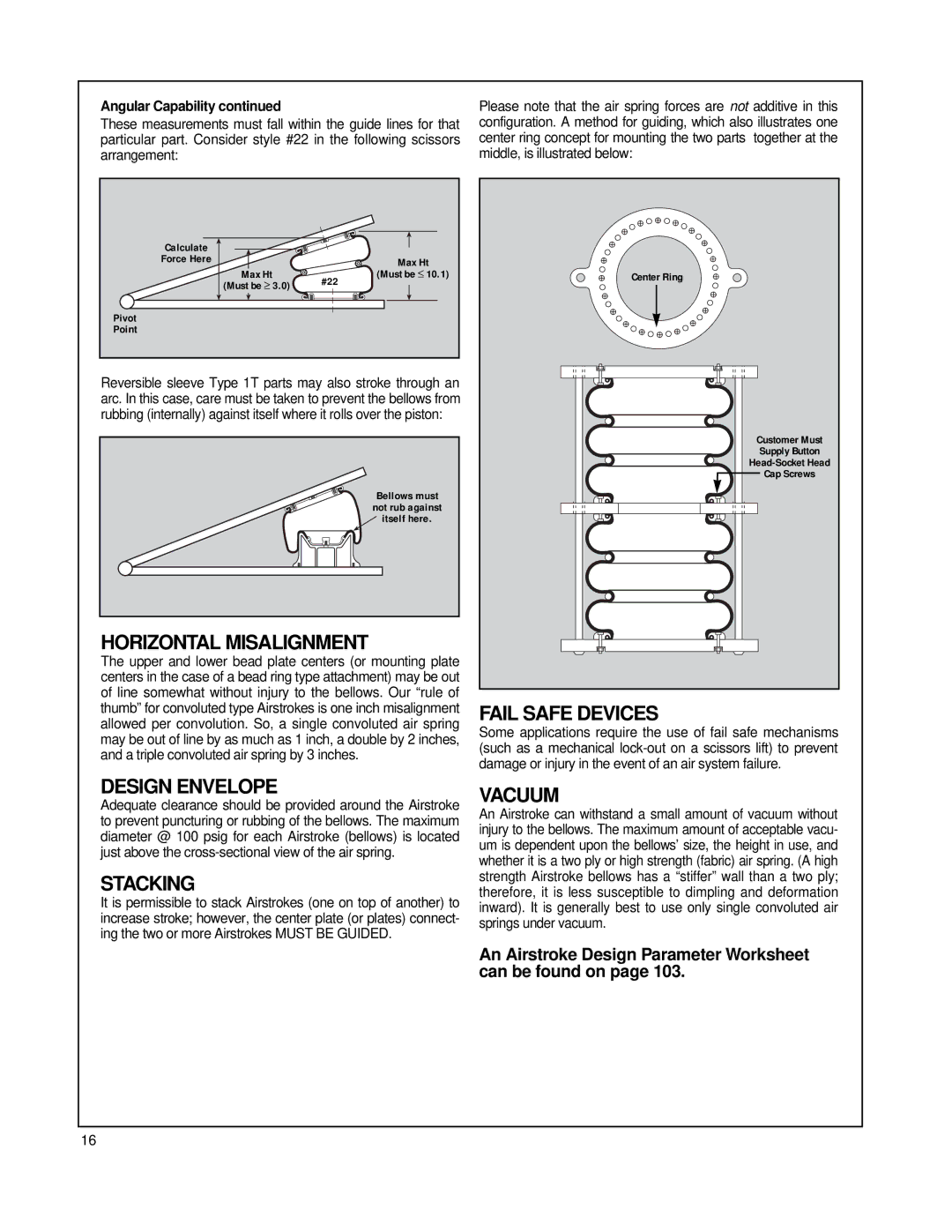

Stacking

Fail Safe Devices

Style

TE Style

Airstroke Actuator Problem Solvers

Forming Press

Vertical Actuated Drive Table Scissor Lift

Airmount Vibration Isolation

Selection and Isolation Formula

Dynamic Spring Rate Formula

Natural Frequency Formula

Lateral Rates and Stability

Center of Gravity

Height Lateral Rate Vertical Rate

Safety Stops

Initial Installation

Isolating AN Unbalanced Mass

LOW Pressure Operation

Plumbing Systems

Damping

Description Order No

Resonance

Isolation Chart Hertz CPM

Percent

Airmount Isolation Problem Solvers

Airmount Isolation Problem Solvers

Miscellaneous Applications

Miscellaneous Problem Solvers

Miscellaneous Problem Solvers

450 400

600 500

470 410 360

10.8

Type 1 bead plate

Type 2 bead plate

Type 3 bead plate

Type 4 bead ring Type 5 rolled plate

Dynamic Characteristics at 2.5 in. Design Height

1M1A

Shaded area without

Consulting Firestone

Description

1M1A-1

Static Data

2M1A

Style NPT, each end 2M1A Plastic studs WO2-358-3002

Ply Brass studs WO2-358-3004

Throughout the stroke

Style Blind nut,1/8 NPT 2M2A Plastic studs WO2-358-3008

2M2A

Psig

Style Blind nuts, 1/4 NPT Blind nuts, 3/4 NPT

NPT only upper plate

Blind nuts lower plate

Rubber bellows only

Shaded area

25 lbs

Style Blind nuts, 1/4 NPT 131 Blind nuts, 3/4 NPT

131

32 lbs

WO1-358-0112

110

Rubber bellows only WO1-358-0100

Strength

116

WO1-358-7606

Dynamic Characteristics at 5.5 in. Design Height

116-1

Area without Consulting Firestone

37 lbs

Volume

115

WO1-358-7023

Dynamic Characteristics at 5.0 in. Design Height

Rubber bellows only WO1-358-0134

Style Blind nuts, 1/4 NPT WO1-358-7040 19-.75

19-.75

10.0 lbs

113

14.5 lbs

Style Blind nuts, 3/4 NPT WO1-358-8160 128-1 High Strength

113-1

15.2 lbs

17.1 lbs

Dynamic Characteristics at 6.0 in. Design Height

Frequency

Do not use Airstroke

119

13.2 lbs

Static Data Description

Able with rolled plates. See page 11 for explanation

126

Rolled Plate Assembly Ply

Bellows Blind nuts, 3/4 NPT WO1-358-7726

WO1-358-0147

Rubber bellows only High Strength

24.5 lbs

148-1

This bead ring

No blind nuts

Ply NPT both ends

No girdle hoop

255-1.5

50 lbs

Dynamic Characteristics at 6.5 in. Design Height

224

Able with bead rings. See pages 8-10 for explanation

14 lbs

Style Blind nuts, 1/4 NPT WO1-358-7325

Blind nuts, 3/4 NPT WO1-358-7327

Rubber bellows only WO1-358-0142

Shaded area without Consulting Firestone

Dynamic Characteristics at 8.5 in. Design Height

X100

20-2

Use

Dynamic Characteristics at 9.5 in. Design Height

Dynamic Characteristics at 10.5 in. Design Height

22-1.5

Style Blind nuts, 1/4 NPT WO1-358-7444 22-1.5

12.9 lbs

100x

21-2

Minimum height

Dynamic Characteristics at 11.25 in. Design Height

233-2

Style Blind nuts, 1/4 NPT

233-2 Blind nuts, 1/4 NPT Two Rubber bumper

Style Two Ply Bellows

19.0 lbs

203

Style Ribbed neck aluminum bead 203 Rings equal spacing

8 bolts, nuts, washers WO1-358-7227

Ribbed neck aluminum bead Ply

Rubber bellows only WO1-139-0207

WO1-358-7239

28.8 lbs

200

Style

200 Rings equal spacing

WO1-358-7775

215

Style Ribbed neck aluminum bead

215 Rings equal spacing

WO1-358-7301 Ribbed neck aluminum bead Bellows

Bead ring Dynamic Characteristics at 11.0 in. Design Height

248-2

72.5 lbs

Force to collapse to minimum height @ 0 PSIG.... lbs

352

Dynamic Characteristics at 13.5 in. Design Height

20.3 lbs

Dynamic Characteristics at 13.0 in. Design Height

313

Style Blind nuts, 1/4 NPT 313

46 lbs

Dynamic Characteristics at 14.70 in. Design Height

333

WO1-358-7760

312

WO1-358-8004

Rubber bellows only WO1-358-7921

323

Do not

Dynamic Characteristics at 14.0 in. Design Height

320

Rubber bellows only WO1-358-0987

Without

Dynamic Characteristics at 15.0 in. Design Height

321

WO1-358-7306

Rubber bellows only WO1-358-7919

348-3

Style Thin wall assembly 1X84D-1 Without cap WO1-358-9188

Dynamic Characteristics at 8.0 in. Design Height

1X84D

With cap dotted line WO1-358-9190

4001

Style Blind nut, 1/8 NPT WO2-358-4001

7002

Style Blind nut, 1/8 NPT WO2-358-7002

7010

Style Blind nut, 1/8 NPT WO2-358-7010

7012

Style Blind nut, 1/8 NPT WO2-358-7012

Ring bolts, nuts, washers not

1T12E-3

Ply Included, use cap screws WO1-358-8118

1T14C-1

Style Blind nuts, 1/4 NPT WO1-358-5405 1T14C-3

1T14C-3

Than 10 Psig internal pressure

1T14C-7

Style Blind nuts, 1/4 NPT WO1-358-5743 1T28C-7 High Strength

Dynamic Characteristics at 7.0 in. Design Height

10.4 lbs

1T15S

13.7 lbs

Style Blind nuts, 1/4 NPT WO1-358-9414 1T15L-4

15.5 lbs

Dynamic Characteristics at 7.5 in. Design Height

Static Data

Available with a bead ring. Bolts are not included

140

WO1-358-9053 Two Blind nuts, 3/4 NPT WO1-358-9054

1T15M-2

WO1-358-9099

1T15M

Dynamic Characteristics at 12.5 in. Design Height

14.3 lbs

Assembly weight bead plate version, no bumper .... .7 lbs

Blind nuts, 3/4 NPT piston Not included WO1-358-0730

18.0 lbs

Style Blind nuts, 1/4 NPT WO1-358-9148

1T19L-7 Blind nuts, 1/4 NPT, bumper WO1-358-9149

Blind nuts, 3/4 NPT WO1-358-9172

Ply Blind nuts, 3/4 NPT, bumper WO1-358-9160

1T19L

22.6 lbs

Index

Airstroke Actuator Design Parameter Worksheet

Airmount Isolator Design Parameter Worksheet

For Vibration Isolation

Airstroke