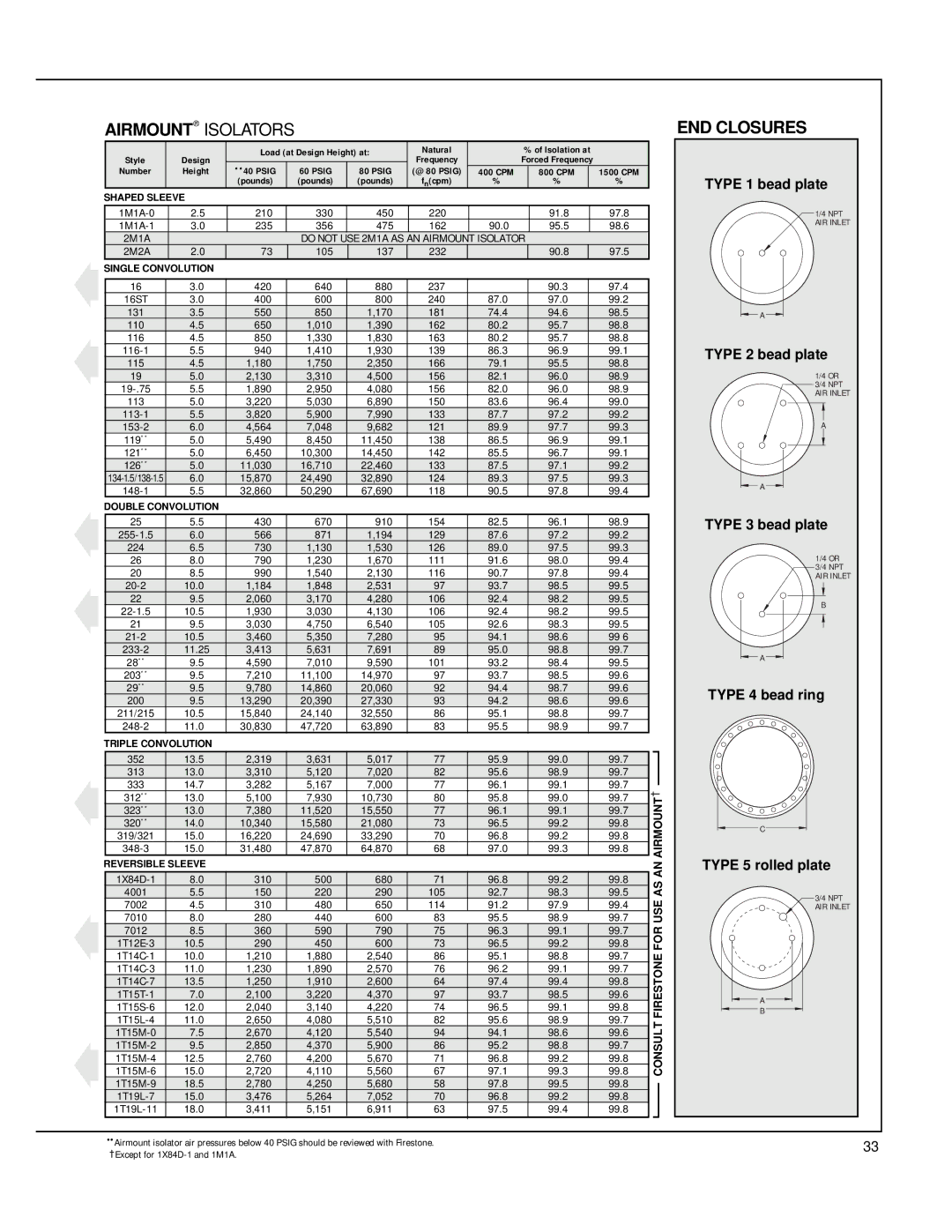

AIRMOUNT® ISOLATORS

|

|

| Load (at Design Height) at: | Natural |

| % of Isolation at |

|

|

|

| |||||

| Style | Design |

|

|

| Frequency |

| Forced Frequency |

|

|

|

| |||

| Number | Height | ••40 PSIG | 60 PSIG | 80 PSIG | (@ 80 PSIG) | 400 CPM |

|

| 800 CPM |

| 1500 CPM |

|

| |

|

|

| (pounds) | (pounds) | (pounds) | fn(cpm) | % |

| % |

| % |

|

|

| |

| SHAPED SLEEVE |

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 2.5 | 210 | 330 | 450 | 220 |

|

| 91.8 |

| 97.8 |

|

|

| ||

| 3.0 | 235 | 356 | 475 | 162 | 90.0 |

|

| 95.5 |

| 98.6 |

|

|

| |

| 2M1A |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| DO NOT USE 2M1A AS AN AIRMOUNT ISOLATOR |

|

|

|

| ||||||||

| 2M2A | 2.0 | 73 | 105 | 137 | 232 |

|

| 90.8 |

| 97.5 |

|

|

| |

➧ | SINGLE CONVOLUTION |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

16 | 3.0 | 420 | 640 | 880 | 237 |

|

| 90.3 |

| 97.4 |

|

|

| ||

|

|

|

|

|

|

| |||||||||

| 16ST | 3.0 | 400 | 600 | 800 | 240 | 87.0 |

| 97.0 |

| 99.2 |

|

|

| |

| 131 | 3.5 | 550 | 850 | 1,170 | 181 | 74.4 |

| 94.6 |

| 98.5 |

|

|

| |

| 110 | 4.5 | 650 | 1,010 | 1,390 | 162 | 80.2 |

| 95.7 |

| 98.8 |

|

|

| |

| 116 | 4.5 | 850 | 1,330 | 1,830 | 163 | 80.2 |

| 95.7 |

| 98.8 |

|

|

| |

➧ | 5.5 | 940 | 1,410 | 1,930 | 139 | 86.3 |

| 96.9 |

| 99.1 |

|

|

| ||

|

|

|

|

|

| ||||||||||

| 115 | 4.5 | 1,180 | 1,750 | 2,350 | 166 | 79.1 |

| 95.5 |

| 98.8 |

|

|

| |

| 19 | 5.0 | 2,130 | 3,310 | 4,500 | 156 | 82.1 |

| 96.0 |

| 98.9 |

|

|

| |

| 5.5 | 1,890 | 2,950 | 4,080 | 156 | 82.0 |

| 96.0 |

| 98.9 |

|

|

| ||

| 113 | 5.0 | 3,220 | 5,030 | 6,890 | 150 | 83.6 |

| 96.4 |

| 99.0 |

|

|

| |

| 5.5 | 3,820 | 5,900 | 7,990 | 133 | 87.7 |

| 97.2 |

| 99.2 |

|

|

| ||

| 6.0 | 4,564 | 7,048 | 9,682 | 121 | 89.9 |

| 97.7 |

| 99.3 |

|

|

| ||

| 119** | 5.0 | 5,490 | 8,450 | 11,450 | 138 | 86.5 |

| 96.9 |

| 99.1 |

|

|

| |

| 121** | 5.0 | 6,450 | 10,300 | 14,450 | 142 | 85.5 |

| 96.7 |

| 99.1 |

|

|

| |

| 126** | 5.0 | 11,030 | 16,710 | 22,460 | 133 | 87.5 |

| 97.1 |

| 99.2 |

|

|

| |

| 6.0 | 15,870 | 24,490 | 32,890 | 124 | 89.3 |

| 97.5 |

| 99.3 |

|

|

| ||

| 5.5 | 32,860 | 50,290 | 67,690 | 118 | 90.5 |

| 97.8 |

| 99.4 |

|

|

| ||

| DOUBLE CONVOLUTION |

|

|

|

|

|

|

|

|

|

|

|

|

| |

➧ | 25 | 5.5 | 430 | 670 | 910 | 154 | 82.5 |

| 96.1 |

| 98.9 |

|

|

| |

6.0 | 566 | 871 | 1,194 | 129 | 87.6 |

| 97.2 |

| 99.2 |

|

|

| |||

| 224 | 6.5 | 730 | 1,130 | 1,530 | 126 | 89.0 |

| 97.5 |

| 99.3 |

|

|

| |

| 26 | 8.0 | 790 | 1,230 | 1,670 | 111 | 91.6 |

| 98.0 |

| 99.4 |

|

|

| |

| 20 | 8.5 | 990 | 1,540 | 2,130 | 116 | 90.7 |

| 97.8 |

| 99.4 |

|

|

| |

| 10.0 | 1,184 | 1,848 | 2,531 | 97 | 93.7 |

| 98.5 |

| 99.5 |

|

|

| ||

➧ | 22 | 9.5 | 2,060 | 3,170 | 4,280 | 106 | 92.4 |

| 98.2 |

| 99.5 |

|

|

| |

10.5 | 1,930 | 3,030 | 4,130 | 106 | 92.4 |

| 98.2 |

| 99.5 |

|

|

| |||

|

|

|

|

|

| ||||||||||

| 21 | 9.5 | 3,030 | 4,750 | 6,540 | 105 | 92.6 |

| 98.3 |

| 99.5 |

|

|

| |

| 10.5 | 3,460 | 5,350 | 7,280 | 95 | 94.1 |

| 98.6 |

| 99 6 |

|

|

| ||

| 11.25 | 3,413 | 5,631 | 7,691 | 89 | 95.0 |

| 98.8 |

| 99.7 |

|

|

| ||

| 28** | 9.5 | 4,590 | 7,010 | 9,590 | 101 | 93.2 |

| 98.4 |

| 99.5 |

|

|

| |

| 203** | 9.5 | 7,210 | 11,100 | 14,970 | 97 | 93.7 |

| 98.5 |

| 99.6 |

|

|

| |

| 29** | 9.5 | 9,780 | 14,860 | 20,060 | 92 | 94.4 |

| 98.7 |

| 99.6 |

|

|

| |

| 200 | 9.5 | 13,290 | 20,390 | 27,330 | 93 | 94.2 |

| 98.6 |

| 99.6 |

|

|

| |

| 211/215 | 10.5 | 15,840 | 24,140 | 32,550 | 86 | 95.1 |

| 98.8 |

| 99.7 |

|

|

| |

| 11.0 | 30,830 | 47,720 | 63,890 | 83 | 95.5 |

| 98.9 |

| 99.7 |

|

|

| ||

| TRIPLE CONVOLUTION |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 352 | 13.5 | 2,319 | 3,631 | 5,017 | 77 | 95.9 |

| 99.0 |

| 99.7 |

|

|

| |

| 313 | 13.0 | 3,310 | 5,120 | 7,020 | 82 | 95.6 |

| 98.9 |

| 99.7 |

|

|

| |

➧ | 333 | 14.7 | 3,282 | 5,167 | 7,000 | 77 | 96.1 |

| 99.1 |

| 99.7 |

|

|

| |

|

|

| † | ||||||||||||

312** | 13.0 | 5,100 | 7,930 | 10,730 | 80 | 95.8 |

| 99.0 |

| 99.7 |

| ||||

|

|

| AIRMOUNT | ||||||||||||

323** | 13.0 | 7,380 | 11,520 | 15,550 | 77 | 96.1 |

| 99.1 |

| 99.7 |

| ||||

320** | 14.0 | 10,340 | 15,580 | 21,080 | 73 | 96.5 |

| 99.2 |

| 99.8 |

|

|

| ||

| 319/321 | 15.0 | 16,220 | 24,690 | 33,290 | 70 | 96.8 |

| 99.2 |

| 99.8 |

|

|

| |

| 15.0 | 31,480 | 47,870 | 64,870 | 68 | 97.0 |

| 99.3 |

| 99.8 |

|

|

| ||

| REVERSIBLE SLEEVE |

|

|

|

|

|

|

|

|

|

|

| AN | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| 8.0 | 310 | 500 | 680 | 71 | 96.8 |

| 99.2 |

| 99.8 |

| ||||

|

|

|

| AS | |||||||||||

| 4001 | 5.5 | 150 | 220 | 290 | 105 | 92.7 |

| 98.3 |

| 99.5 |

| |||

| 7002 | 4.5 | 310 | 480 | 650 | 114 | 91.2 |

| 97.9 |

| 99.4 |

| USE | ||

➧ | 7010 | 8.0 | 280 | 440 | 600 | 83 | 95.5 | 98.9 |

| 99.7 |

| ||||

7012 | 8.5 | 360 | 590 | 790 | 75 | 96.3 |

| 99.1 |

| 99.7 |

| FOR | |||

10.5 | 290 | 450 | 600 | 73 | 96.5 |

| 99.2 |

| 99.8 |

| |||||

10.0 | 1,210 | 1,880 | 2,540 | 86 | 95.1 |

| 98.8 |

| 99.7 |

| FIRESTONE | ||||

| 11.0 | 1,230 | 1,890 | 2,570 | 76 | 96.2 |

| 99.1 |

| 99.7 |

| ||||

|

|

|

|

|

| ||||||||||

| 13.5 | 1,250 | 1,910 | 2,600 | 64 | 97.4 |

| 99.4 |

| 99.8 |

|

|

| ||

| 7.0 | 2,100 | 3,220 | 4,370 | 97 | 93.7 |

| 98.5 |

| 99.6 |

|

|

| ||

| 12.0 | 2,040 | 3,140 | 4,220 | 74 | 96.5 |

| 99.1 |

| 99.8 |

|

|

| ||

| 11.0 | 2,650 | 4,080 | 5,510 | 82 | 95.6 |

| 98.9 |

| 99.7 |

| CONSULT | |||

| 15.0 | 2,720 | 4,110 | 5,560 | 67 | 97.1 |

| 99.3 |

| 99.8 |

| ||||

| 7.5 | 2,670 | 4,120 | 5,540 | 94 | 94.1 |

| 98.6 |

| 99.6 |

|

|

| ||

➧ | 9.5 | 2,850 | 4,370 | 5,900 | 86 | 95.2 |

| 98.8 |

| 99.7 |

|

|

| ||

12.5 | 2,760 | 4,200 | 5,670 | 71 | 96.8 |

| 99.2 |

| 99.8 |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

18.5 | 2,780 | 4,250 | 5,680 | 58 | 97.8 |

| 99.5 |

| 99.8 |

|

|

| |||

|

|

|

|

| |||||||||||

| 15.0 | 3,476 | 5,264 | 7,052 | 70 | 96.8 |

| 99.2 |

| 99.8 |

|

|

| ||

| 18.0 | 3,411 | 5,151 | 6,911 | 63 | 97.5 |

| 99.4 |

| 99.8 |

|

|

| ||

END CLOSURES

TYPE 1 bead plate

1/4 NPT AIR INLET

A

TYPE 2 bead plate

1/4 OR

3/4 NPT AIR INLET

A

A

TYPE 3 bead plate

1/4 OR

3/4 NPT AIR INLET

B

A

TYPE 4 bead ring

C

TYPE 5 rolled plate

3/4 NPT AIR INLET

A

B

•• Airmount isolator air pressures below 40 PSIG should be reviewed with Firestone. | 33 | |

† Except for | ||

|