Ti30 specifications

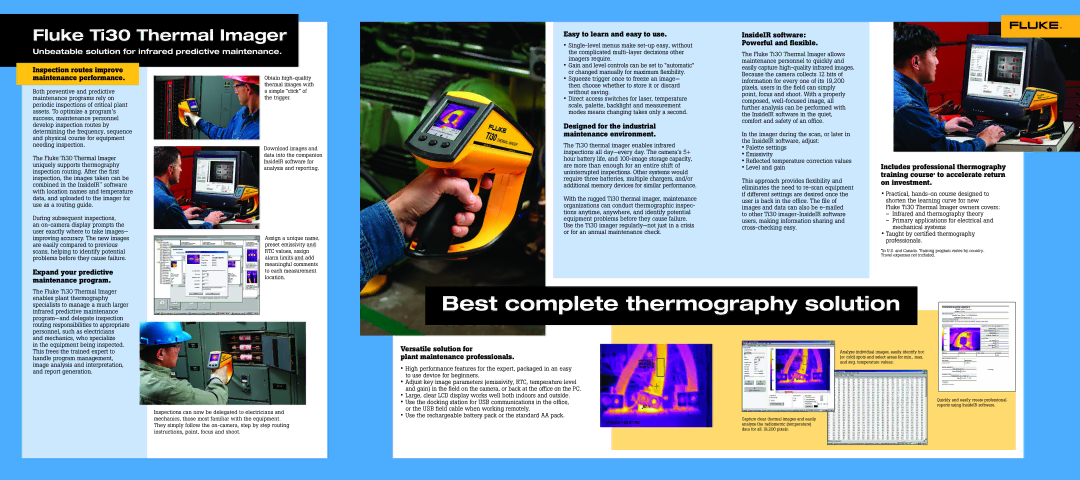

The Fluke Ti30 is a powerful thermal imaging camera designed for professionals who require accurate temperature measurements and efficient diagnostics. It combines advanced technologies with user-friendly features to deliver an exceptional tool for maintenance, electrical, mechanical, and building inspection applications.One of the standout features of the Ti30 is its impressive thermal sensitivity, which enables it to detect minute temperature differences. With a sensitivity of less than 0.05°C, this camera allows users to identify potential issues before they escalate into more significant problems. This capability is particularly important in electrical inspections and mechanical troubleshooting, where overheating components could indicate failure.

The Ti30 is equipped with a high-resolution 240 x 180 pixel Focal Plane Array (FPA) detector, which provides clear and detailed thermal imagery. This resolution allows users to discern temperature variations across surfaces and identify hotspots with precision. The camera's ability to provide accurate thermal images translates into more reliable assessments and quicker decision-making.

In addition to its impressive imaging capabilities, the Fluke Ti30 features Fluke’s innovative IR-Fusion technology. This technology allows users to overlay visible images with thermal images, creating a composite view that enhances the understanding of temperature anomalies. This feature is particularly useful in building diagnostics, as it helps pinpoint the exact locations of insulation issues or moisture ingress.

Another important characteristic of the Ti30 is its rugged design. Built to withstand harsh conditions, the camera is IP54 rated for dust and moisture resistance, making it suitable for outdoor use and industrial environments. Moreover, it has been drop-tested from a height of 2 meters, ensuring reliability and durability on the job site.

The Fluke Ti30 also includes various user-friendly functionalities such as on-screen temperature measurements, adjustable emissivity settings, and an intuitive interface. These features enable users to operate the camera with ease, even in challenging situations. The built-in Wi-Fi capability allows for seamless sharing of images and reports, facilitating better collaboration among team members.

Overall, the Fluke Ti30 thermal imaging camera stands out in the market due to its advanced technology, robust features, and user-friendly design. It is an essential tool for professionals in various industries, helping them improve efficiency, enhance safety, and reduce costs through early detection of potential problems.