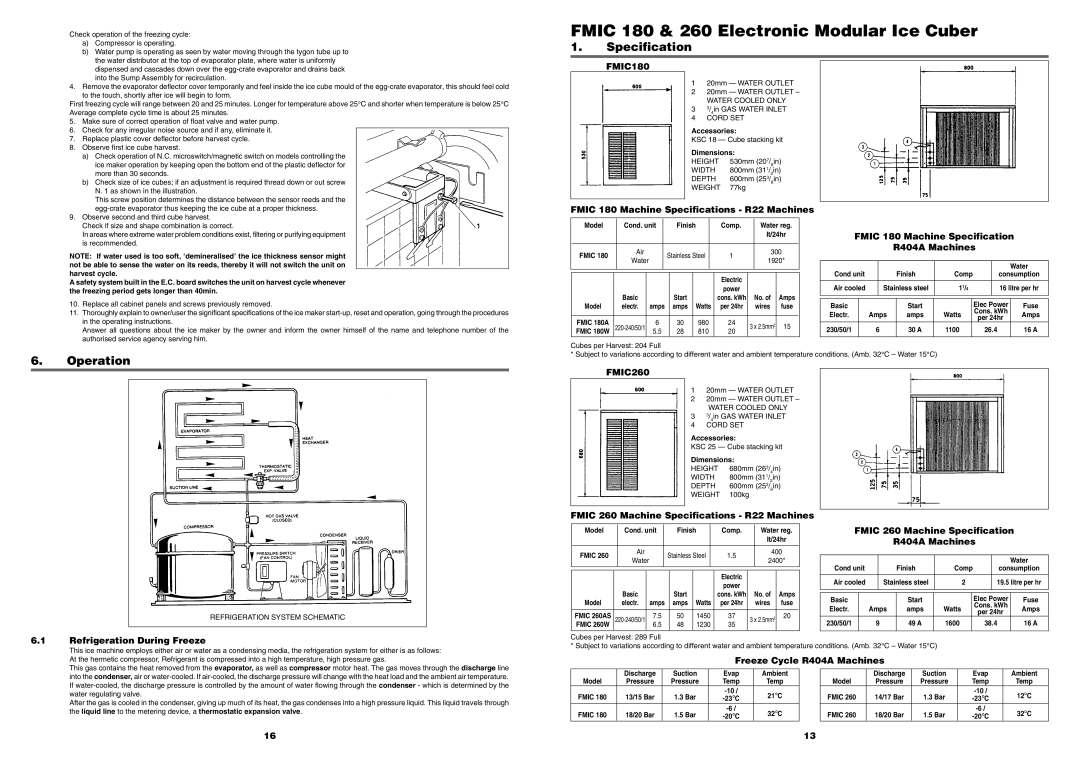

FMIC180 specifications

The Foster FMIC180 is a cutting-edge industrial fan designed for optimal airflow and efficient cooling in various environments. This powerful fan is ideal for use in production facilities, workshops, and large commercial spaces, where maintaining a stable temperature is crucial for both equipment and personnel comfort. With its impressive features and robust design, the FMIC180 stands out in the competitive market of industrial fans.One of the standout characteristics of the FMIC180 is its high-performance motor, which delivers substantial airflow while ensuring energy efficiency. The motor is built with durable materials, providing longevity and reliable operation even in demanding conditions. Additionally, the FMIC180 is equipped with a variable speed control system, allowing users to adjust the airflow according to their specific needs. This versatility makes it suitable for a variety of applications, from gentle air circulation to powerful cooling.

The design of the FMIC180 emphasizes user-friendliness and ease of maintenance. Its lightweight structure allows for effortless relocation within the workspace, while integrated handles enhance maneuverability. The fan’s easy-access components simplify routine maintenance tasks, ensuring that it remains in peak operating condition with minimal effort.

An essential feature of the Foster FMIC180 is its robust build quality. Constructed with high-grade materials, the fan is designed to withstand the rigors of industrial environments. Its protective housing guards against dust and debris, ensuring reliable performance even in challenging conditions. The fan’s blades are aerodynamically designed to maximize airflow efficiency, reducing the energy consumption typically associated with high-volume fans.

In terms of safety, the FMIC180 includes built-in thermal protection that prevents overheating and potential damage to the motor during extended use. Its stable base design minimizes vibrations, providing a secure operation without the risk of tipping over.

The Foster FMIC180 prioritizes compatibility and integration within existing industrial setups. Its standard power requirements allow for seamless connection to existing electrical systems, making installation straightforward. With these advanced features and technologies, the Foster FMIC180 emerges as an essential component in industrial cooling solutions, promoting enhanced airflow and operational efficiency across various applications. Its combination of performance, durability, and user-centric design makes it a reliable choice for businesses looking to improve their environmental conditions while ensuring energy efficiency.