PREPARING THE RANGE HOOD

1.Unpack hood and check contents. You should receive:

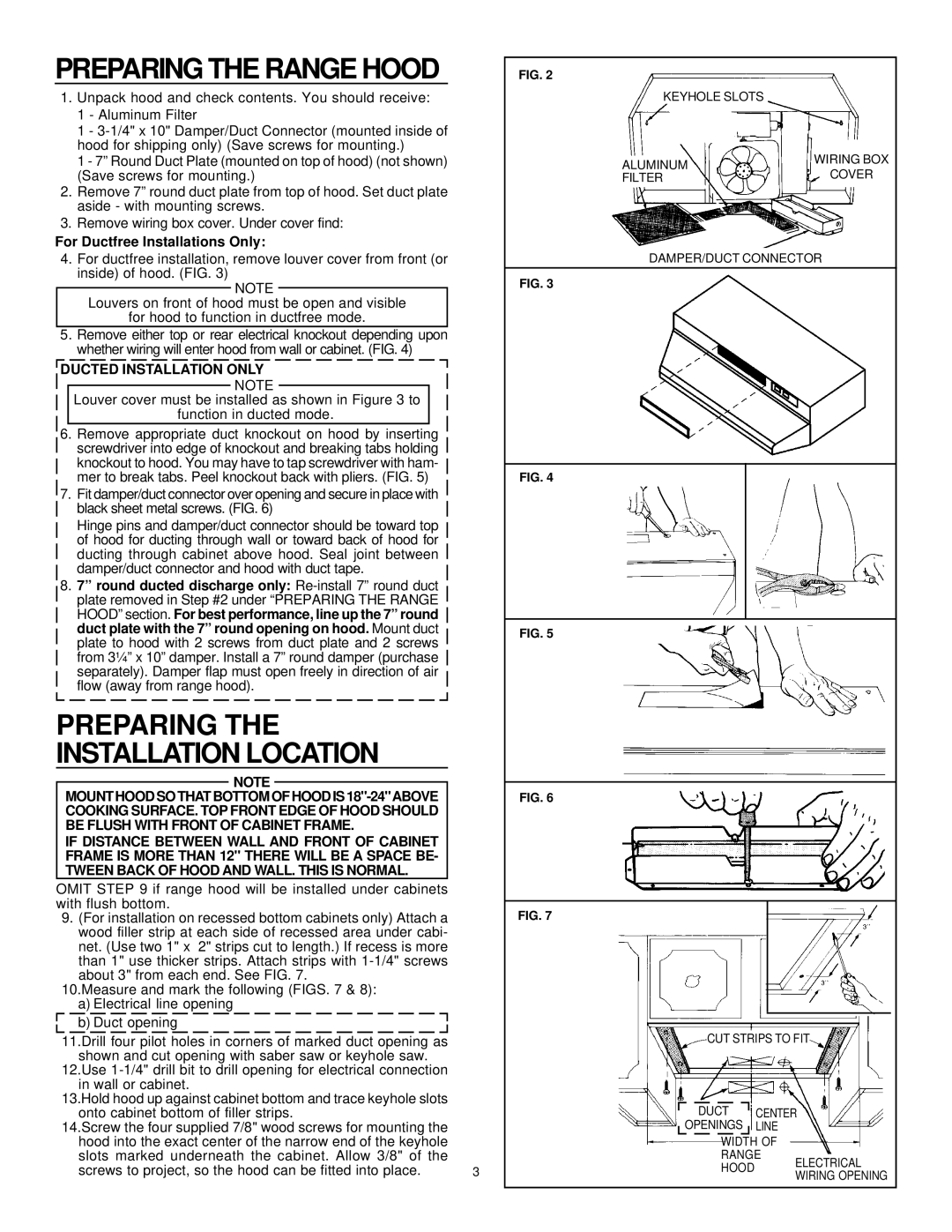

1 - Aluminum Filter

1 -

1 - 7” Round Duct Plate (mounted on top of hood) (not shown) (Save screws for mounting.)

2.Remove 7” round duct plate from top of hood. Set duct plate aside - with mounting screws.

3.Remove wiring box cover. Under cover find:

For Ductfree Installations Only:

4.For ductfree installation, remove louver cover from front (or inside) of hood. (FIG. 3)

NOTE

Louvers on front of hood must be open and visible

for hood to function in ductfree mode.

5.Remove either top or rear electrical knockout depending upon whether wiring will enter hood from wall or cabinet. (FIG. 4)

DUCTED INSTALLATION ONLY

NOTE

Louver cover must be installed as shown in Figure 3 to function in ducted mode.

6.Remove appropriate duct knockout on hood by inserting screwdriver into edge of knockout and breaking tabs holding knockout to hood. You may have to tap screwdriver with ham- mer to break tabs. Peel knockout back with pliers. (FIG. 5)

7.Fit damper/duct connector over opening and secure in place with black sheet metal screws. (FIG. 6)

Hinge pins and damper/duct connector should be toward top of hood for ducting through wall or toward back of hood for ducting through cabinet above hood. Seal joint between damper/duct connector and hood with duct tape.

8.7” round ducted discharge only:

PREPARING THE INSTALLATION LOCATION

NOTE

IF DISTANCE BETWEEN WALL AND FRONT OF CABINET FRAME IS MORE THAN 12" THERE WILL BE A SPACE BE- TWEEN BACK OF HOOD AND WALL. THIS IS NORMAL.

OMIT STEP 9 if range hood will be installed under cabinets with flush bottom.

9.(For installation on recessed bottom cabinets only) Attach a wood filler strip at each side of recessed area under cabi- net. (Use two 1" x 2" strips cut to length.) If recess is more than 1" use thicker strips. Attach strips with

about 3" from each end. See FIG. 7. 10.Measure and mark the following (FIGS. 7 & 8):

a) Electrical line opening |

|

b) Duct opening |

|

11.Drill four pilot holes in corners of marked duct opening as |

|

shown and cut opening with saber saw or keyhole saw. |

|

12.Use |

|

in wall or cabinet. |

|

13.Hold hood up against cabinet bottom and trace keyhole slots |

|

onto cabinet bottom of filler strips. |

|

14.Screw the four supplied 7/8" wood screws for mounting the |

|

hood into the exact center of the narrow end of the keyhole |

|

slots marked underneath the cabinet. Allow 3/8" of the |

|

screws to project, so the hood can be fitted into place. | 3 |

FIG. 2

KEYHOLE SLOTS |

|

|

| |||||||

|

|

|

|

|

|

|

|

| WIRING | BOX |

|

|

|

|

|

|

|

|

| ||

ALUMINUM |

| |||||||||

| COVER | |||||||||

FILTER |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DAMPER/DUCT CONNECTOR

FIG. 3

FIG. 4

FIG. 5

FIG. 6

FIG. 7

CUT STRIPS TO FIT

DUCT CENTER

OPENINGS LINE

WIDTH OF

RANGE

HOOD ELECTRICAL

WIRING OPENING