CAUTION: TO SERVICE MACHINE, POWER MUST BE DISCONNECTED!

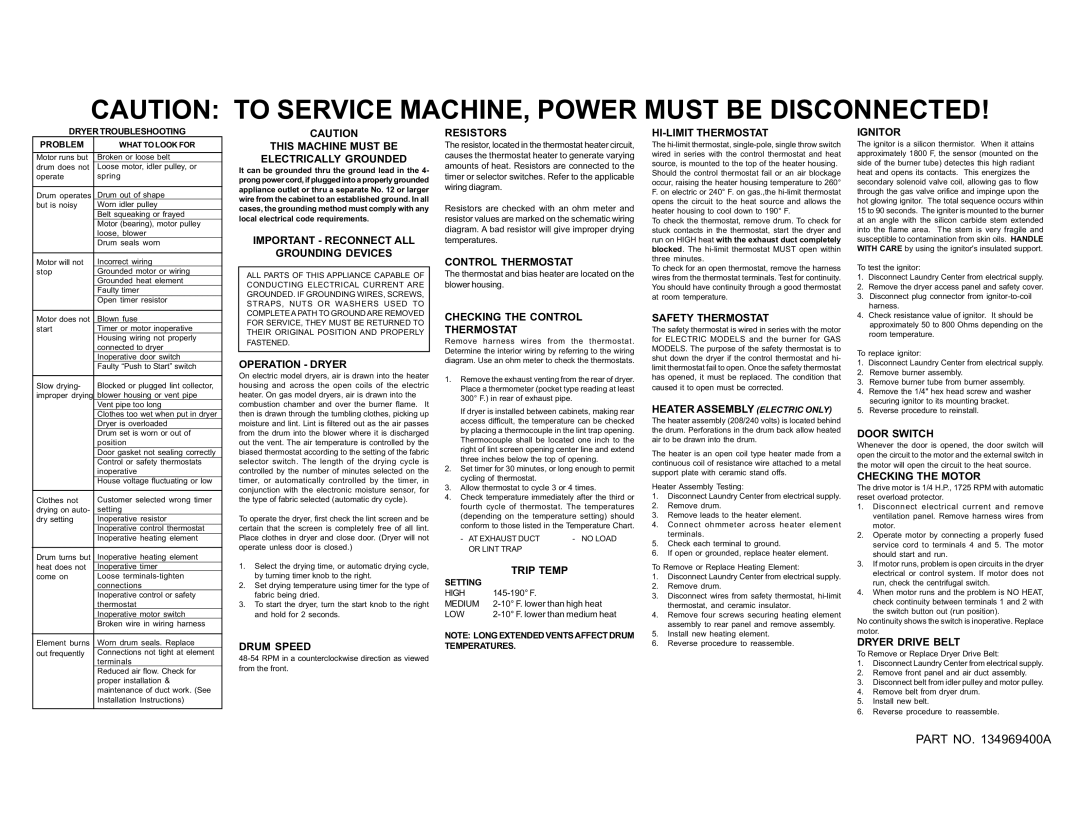

DRYER TROUBLESHOOTING

PROBLEM | WHAT TO LOOK FOR |

Motor runs but | Broken or loose belt |

drum does not | Loose motor, idler pulley, or |

operate | spring |

|

|

Drum operates | Drum out of shape |

but is noisy | Worn idler pulley |

| Belt squeaking or frayed |

| Motor (bearing), motor pulley |

| loose, blower |

| Drum seals worn |

|

|

Motor will not | Incorrect wiring |

stop | Grounded motor or wiring |

| Grounded heat element |

| Faulty timer |

| Open timer resistor |

|

|

Motor does not | Blown fuse |

start | Timer or motor inoperative |

| Housing wiring not properly |

| connected to dryer |

| Inoperative door switch |

| Faulty “Push to Start” switch |

|

|

Slow drying- | Blocked or plugged lint collector, |

improper drying | blower housing or vent pipe |

| Vent pipe too long |

| Clothes too wet when put in dryer |

| Dryer is overloaded |

| Drum set is worn or out of |

| position |

| Door gasket not sealing correctly |

| Control or safety thermostats |

| inoperative |

| House voltage fluctuating or low |

|

|

Clothes not | Customer selected wrong timer |

drying on auto- | setting |

dry setting | Inoperative resistor |

| Inoperative control thermostat |

| Inoperative heating element |

|

|

Drum turns but | Inoperative heating element |

heat does not | Inoperative timer |

come on | Loose |

| connections |

| Inoperative control or safety |

| thermostat |

| Inoperative motor switch |

| Broken wire in wiring harness |

|

|

Element burns | Worn drum seals. Replace |

out frequently | Connections not tight at element |

| terminals |

| Reduced air flow. Check for |

| proper installation & |

| maintenance of duct work. (See |

| Installation Instructions) |

|

|

CAUTION

THIS MACHINE MUST BE

ELECTRICALLY GROUNDED

It can be grounded thru the ground lead in the 4- prong power cord, if plugged into a properly grounded appliance outlet or thru a separate No. 12 or larger wire from the cabinet to an established ground. In all cases, the grounding method must comply with any local electrical code requirements.

IMPORTANT - RECONNECT ALL

GROUNDING DEVICES

ALL PARTS OF THIS APPLIANCE CAPABLE OF CONDUCTING ELECTRICAL CURRENT ARE GROUNDED. IF GROUNDING WIRES, SCREWS, STRAPS, NUTS OR WASHERS USED TO COMPLETE A PATH TO GROUND ARE REMOVED FOR SERVICE, THEY MUST BE RETURNED TO THEIR ORIGINAL POSITION AND PROPERLY FASTENED.

OPERATION - DRYER

On electric model dryers, air is drawn into the heater housing and across the open coils of the electric heater. On gas model dryers, air is drawn into the combustion chamber and over the burner flame. It then is drawn through the tumbling clothes, picking up moisture and lint. Lint is filtered out as the air passes from the drum into the blower where it is discharged out the vent. The air temperature is controlled by the biased thermostat according to the setting of the fabric selector switch. The length of the drying cycle is controlled by the number of minutes selected on the timer, or automatically controlled by the timer, in conjunction with the electronic moisture sensor, for the type of fabric selected (automatic dry cycle).

To operate the dryer, first check the lint screen and be certain that the screen is completely free of all lint. Place clothes in dryer and close door. (Dryer will not operate unless door is closed.)

1.Select the drying time, or automatic drying cycle, by turning timer knob to the right.

2.Set drying temperature using timer for the type of fabric being dried.

3.To start the dryer, turn the start knob to the right and hold for 2 seconds.

DRUM SPEED

RESISTORS

The resistor, located in the thermostat heater circuit, causes the thermostat heater to generate varying amounts of heat. Resistors are connected to the timer or selector switches. Refer to the applicable wiring diagram.

Resistors are checked with an ohm meter and resistor values are marked on the schematic wiring diagram. A bad resistor will give improper drying temperatures.

CONTROL THERMOSTAT

The thermostat and bias heater are located on the blower housing.

CHECKING THE CONTROL

THERMOSTAT

Remove harness wires from the thermostat. Determine the interior wiring by referring to the wiring diagram. Use an ohm meter to check the thermostats.

1.Remove the exhaust venting from the rear of dryer. Place a thermometer (pocket type reading at least 300° F.) in rear of exhaust pipe.

If dryer is installed between cabinets, making rear access difficult, the temperature can be checked by placing a thermocouple in the lint trap opening. Thermocouple shall be located one inch to the right of lint screen opening center line and extend three inches below the top of opening.

2.Set timer for 30 minutes, or long enough to permit cycling of thermostat.

3.Allow thermostat to cycle 3 or 4 times.

4.Check temperature immediately after the third or fourth cycle of thermostat. The temperatures (depending on the temperature setting) should conform to those listed in the Temperature Chart.

- AT EXHAUST DUCT | - NO LOAD |

OR LINT TRAP |

|

SETTING | TRIP TEMP |

| |

HIGH | |

MEDIUM | |

LOW |

NOTE: LONGEXTENDEDVENTSAFFECTDRUM TEMPERATURES.

HI-LIMIT THERMOSTAT

The

To check the thermostat, remove drum. To check for stuck contacts in the thermostat, start the dryer and run on HIGH heat with the exhaust duct completely blocked. The

To check for an open thermostat, remove the harness wires from the thermostat terminals. Test for continuity. You should have continuity through a good thermostat at room temperature.

SAFETY THERMOSTAT

The safety thermostat is wired in series with the motor for ELECTRIC MODELS and the burner for GAS MODELS. The purpose of the safety thermostat is to shut down the dryer if the control thermostat and hi- limit thermostat fail to open. Once the safety thermostat has opened, it must be replaced. The condition that caused it to open must be corrected.

HEATER ASSEMBLY (ELECTRIC ONLY)

The heater assembly (208/240 volts) is located behind the drum. Perforations in the drum back allow heated air to be drawn into the drum.

The heater is an open coil type heater made from a continuous coil of resistance wire attached to a metal support plate with ceramic stand offs.

Heater Assembly Testing:

1.Disconnect Laundry Center from electrical supply.

2.Remove drum.

3.Remove leads to the heater element.

4.Connect ohmmeter across heater element terminals.

5.Check each terminal to ground.

6.If open or grounded, replace heater element.

To Remove or Replace Heating Element:

1.Disconnect Laundry Center from electrical supply.

2.Remove drum.

3.Disconnect wires from safety thermostat,

4.Remove four screws securing heating element assembly to rear panel and remove assembly.

5.Install new heating element.

6.Reverse procedure to reassemble.

IGNITOR

The ignitor is a silicon thermistor. When it attains approximately 1800 F, the sensor (mounted on the side of the burner tube) detectes this high radiant heat and opens its contacts. This energizes the secondary solenoid valve coil, allowing gas to flow through the gas valve orifice and impinge upon the hot glowing ignitor. The total sequence occurs within 15 to 90 seconds. The igniter is mounted to the burner at an angle with the silicon carbide stem extended into the flame area. The stem is very fragile and susceptible to contamination from skin oils. HANDLE WITH CARE by using the ignitor's insulated support.

To test the ignitor:

1.Disconnect Laundry Center from electrical supply.

2.Remove the dryer access panel and safety cover.

3.Disconnect plug connector from

4.Check resistance value of ignitor. It should be approximately 50 to 800 Ohms depending on the room temperature.

To replace ignitor:

1.Disconnect Laundry Center from electrical supply.

2.Remove burner assembly.

3.Remove burner tube from burner assembly.

4.Remove the 1/4" hex head screw and washer securing ignitor to its mounting bracket.

5.Reverse procedure to reinstall.

DOOR SWITCH

Whenever the door is opened, the door switch will open the circuit to the motor and the external switch in the motor will open the circuit to the heat source.

CHECKING THE MOTOR

The drive motor is 1/4 H.P., 1725 RPM with automatic reset overload protector.

1.Disconnect electrical current and remove ventilation panel. Remove harness wires from motor.

2.Operate motor by connecting a properly fused service cord to terminals 4 and 5. The motor should start and run.

3.If motor runs, problem is open circuits in the dryer electrical or control system. If motor does not run, check the centrifugal switch.

4.When motor runs and the problem is NO HEAT,

check continuity between terminals 1 and 2 with the switch button out (run position).

No continuity shows the switch is inoperative. Replace motor.

DRYER DRIVE BELT

To Remove or Replace Dryer Drive Belt:

1.Disconnect Laundry Center from electrical supply.

2.Remove front panel and air duct assembly.

3.Disconnect belt from idler pulley and motor pulley.

4.Remove belt from dryer drum.

5.Install new belt.

6.Reverse procedure to reassemble.

PART NO. 134969400A