8196203 specifications

The Frymaster 8196203 is a highly regarded commercial fryer that has carved a niche in the fast-paced environment of restaurants and food service operations. This unit combines advanced technology with robust design, making it an ideal choice for those who demand efficiency and consistency in their frying processes.One of the standout features of the Frymaster 8196203 is its high-capacity frying system. With the ability to handle large batches, this fryer is perfect for busy kitchens that require quick service without sacrificing food quality. The unit is engineered to provide optimal heating, ensuring that oil is quickly brought to the desired frying temperature, reducing wait times and improving overall productivity.

The Frymaster 8196203 is equipped with a powerful heating system that utilizes innovative technologies for enhanced performance. It often includes options for both gas and electric heating, catering to the specific needs of various kitchen environments. The unit's design promotes even heat distribution, reducing the risk of uneven cooking and guaranteeing that every piece of food is crisped to perfection.

Furthermore, the fryer features a sophisticated filtration system that helps maintain oil quality. This system automatically filters out food particles and other impurities, extending the life of the cooking oil and ensuring that the flavor of the food remains untainted. As a result, operators can save on oil costs while also ensuring food quality stays high.

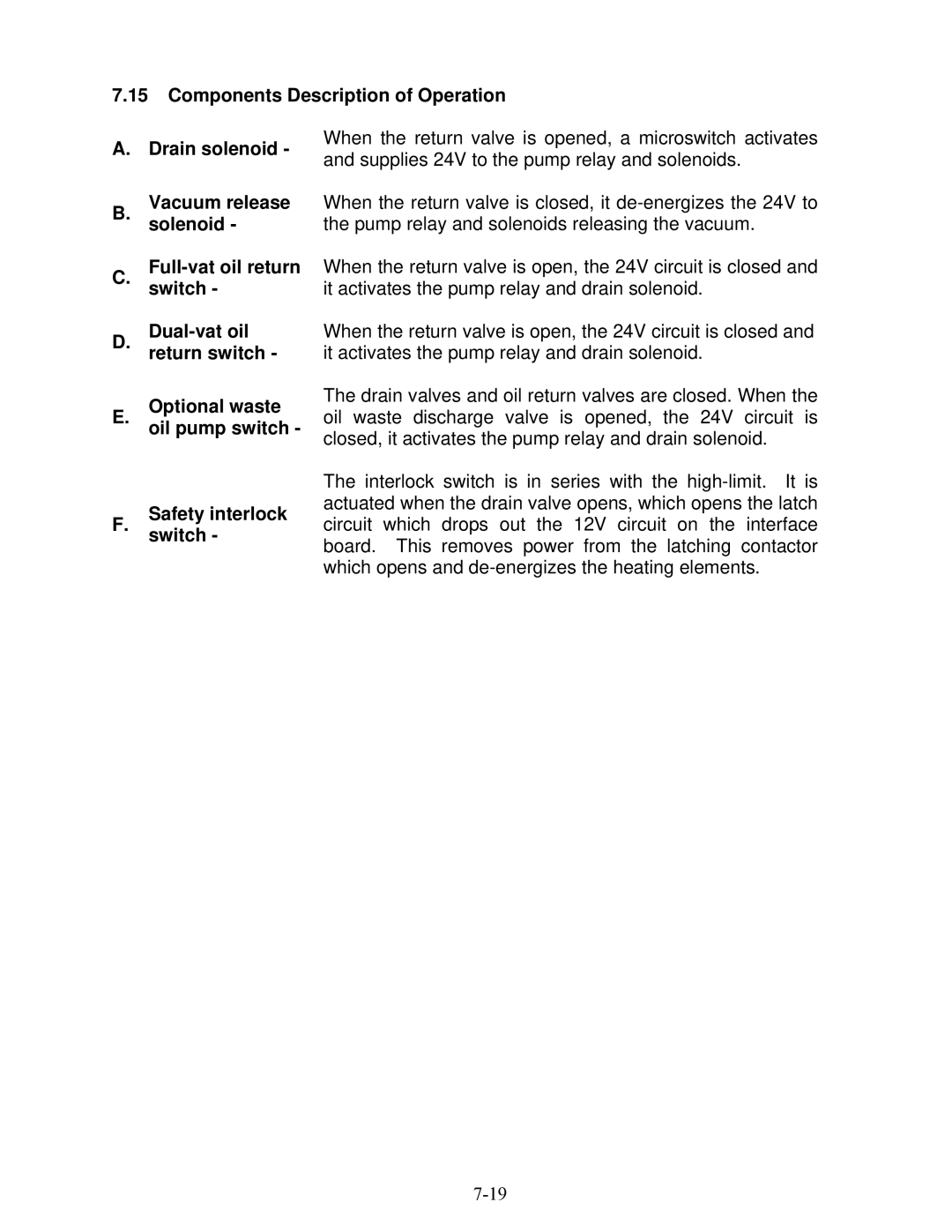

Safety is another important aspect of the Frymaster 8196203, which includes built-in features such as temperature controls and safety shut-off mechanisms. These features help prevent overheating and accidents, allowing kitchen staff to focus on cooking rather than constantly monitoring the fryer.

The Frymaster 8196203 is designed with user-friendliness in mind. Its intuitive control panel allows for easy adjustments and monitoring, ensuring that cooks can operate it with minimal training. Additionally, the fryer is constructed with durable materials that are easy to clean, which is essential for maintaining hygiene in any food service environment.

In conclusion, the Frymaster 8196203 is a reliable commercial fryer that stands out for its high capacity, advanced heating technology, and efficiency-enhancing features. With a focus on safety, ease of use, and maintenance, it’s a valuable addition to any kitchen, helping chefs produce mouth-watering fried dishes with speed and consistency.