19211, 19210 specifications

The GE 19210 and GE 19211 are advanced gas turbine engines developed by General Electric for various aviation and industrial applications. These engines exemplify the innovative spirit of GE's engineering, designed to provide reliable performance, efficiency, and versatility across a wide range of operational environments.One of the defining features of the GE 19210 and 19211 is their high-efficiency design. These turbines utilize advanced materials and manufacturing techniques, which contribute to their lightweight construction and improved fuel efficiency. The engines are capable of maintaining high power output while consuming less fuel compared to earlier models. This efficiency not only reduces operational costs but also minimizes the environmental impact, making them an attractive choice for operators focused on sustainability.

Both the GE 19210 and 19211 incorporate state-of-the-art aerodynamics in their compressor and turbine sections. The optimized blade design increases airflow, enhancing overall performance and thrust capability. The engines are equipped with multiple stages of compression that significantly boost the pressure before combustion, ensuring that the power produced during operation is maximized.

Another significant characteristic of these gas turbines is their advanced control systems. GE has integrated sophisticated electronic control units that allow for real-time monitoring and adjustment of engine parameters. This results in improved responsiveness, optimized performance across various flight profiles, and enhanced safety. Operators can easily manage engine operations, making the GE 19210 and 19211 adaptable for differing mission requirements.

Additionally, the maintenance and serviceability of these engines have been a priority in their design. GE has engineered the 19210 and 19211 with modular components that facilitate quick inspections and repairs, reducing downtime and operational disruptions. The availability of parts and support services ensures that operators can maintain their fleet efficiently.

In summary, the GE 19210 and 19211 gas turbine engines are benchmarks in aviation technology, characterized by high efficiency, advanced aerodynamics, sophisticated control systems, and ease of maintenance. Their design and features position them as reliable solutions for both commercial and industrial stakeholders looking to achieve superior performance with an emphasis on sustainability and operational effectiveness. As GE continues to innovate, these engines represent a commitment to excellence in the field of gas turbine technology.

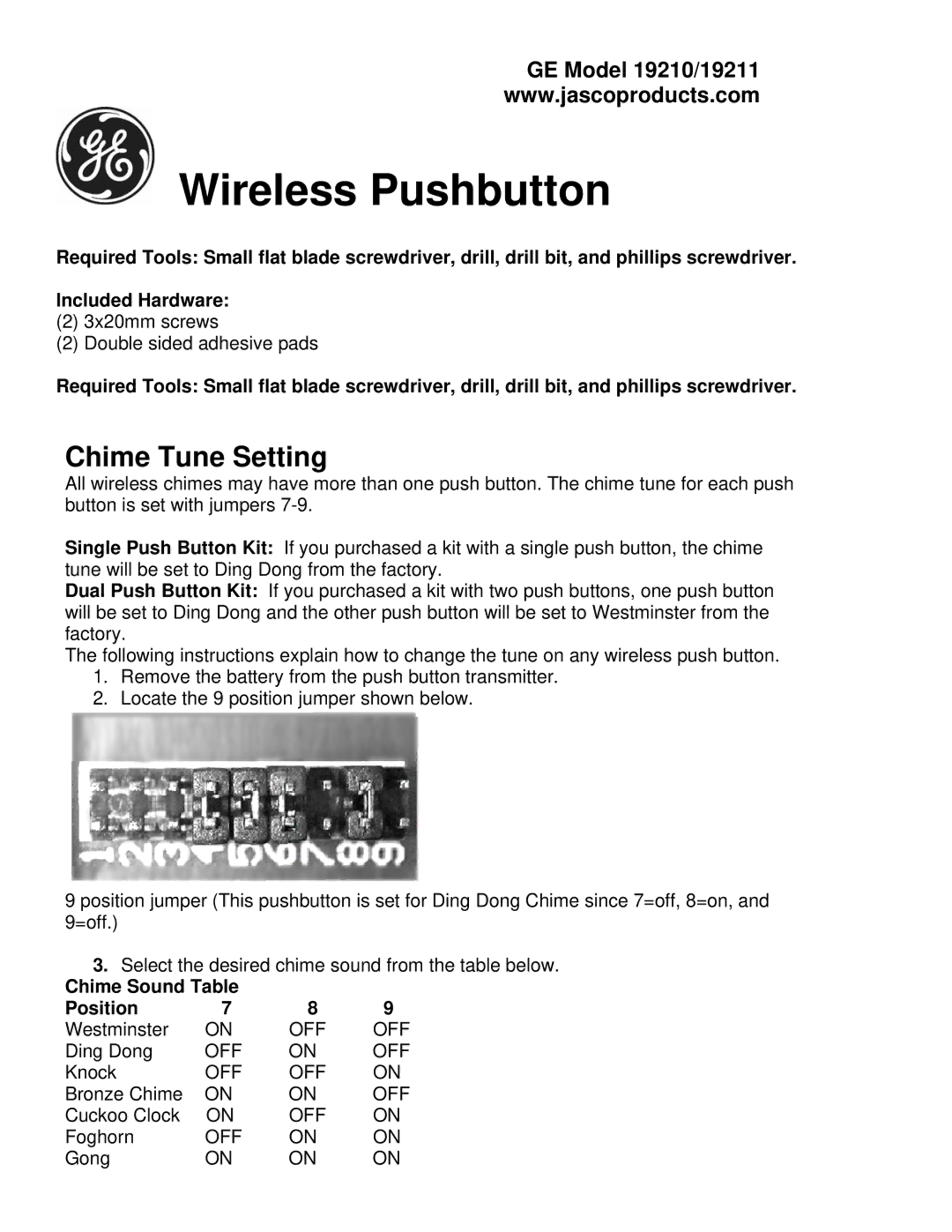

Wireless Pushbutton

Wireless Pushbutton