DANGER

POWER SYSTEMS, INC

DEADLY EXHAUST FUMES. OUTDOOR INSTALLATION ONLY

POWER SYSTEMS

‹CONTENTS

INTRODUCTION

AUTHORIZED DEALER LOCATION

DANGER

Introduction

GENERAL HAZARDS

Despite the safe design of this generator

Parts of the generator are rotating and/or hot

‹STANDARDS INDEX

ELECTRICAL HAZARDS

FIRE HAZARDS

EXPLOSION HAZARDS

1.1UNPACKING/INSPECTION

1.2PROTECTION SYSTEMS

1.3SYSTEM SET LED

1.4YOUR GENERATOR

Figure 1.1 - 7 kW, Single Cylinder GH-410Engine

Figure 1.2 - 12 kW and 15 kW, V-twin GT-990Engine

1.5 SPECIFICATIONS

‹ 1.5.1 GENERATOR

‹1.5.2 ENGINE

DANGER

1.8RECONFIGURING THE FUEL SYSTEM

1.6FUEL REQUIREMENTS AND RECOMMENDATIONS

1.7FUEL CONSUMPTION

1.9.1 GENERATOR

1.10 BATTERY INSTALLATION

1.9LOCATION

1.9.2 TRANSFER SWITCH

Do not open or mutilate the battery. Released

1.11 THE BATTERY

Figure 1.5 - Battery Cable Connections

Wear rubber gloves and boots

Never operate the engine with the oil level

2.2CHECK TRANSFER SWITCH OPERATION

2.1BEFORE INITIAL START-UP

2.3ELECTRICAL CHECKS

2.6ADJUSTING THE REGULATOR NATURAL GAS ONLY

2.4GENERATOR TESTS UNDER LOAD

2.5CHECKING AUTOMATIC OPERATION

Do not make any unnecessary adjustments

2.7ENGINE GOVERNOR ADJUSTMENT

Figure 2.2 - Placement of Regulator

Figure 2.3 - Engine Governor Adjustment

Figure 2.5 - Voltage Adjustment Potentiometer

2.8VOLTAGE REGULATOR ADJUSTMENT

3.1BREAK-INPROCEDURE

Figure 2.4 - Full Load Speed Adjust Screw

3.4SEQUENCE OF AUTOMATIC OPERATION

3.3AUTOMATIC TRANSFER OPERATION

3.2USING THE AUTO/OFF/MANUAL SWITCH FIGURE

With the switch set to AUTO, the engine may

Figure 3.2 - Manual Transfer Switch Operation

3.6SETTING THE EXERCISE TIMER

3.5MANUAL TRANSFER OPERATION

‹3.5.2 TRANSFER BACK TO UTILITY POWER SOURCE

‹3.7.2 HIGH TEMPERATURE SWITCH

3.7PROTECTION SYSTEMS

4.1FUSE

‹3.7.1 LOW OIL PRESSURE SWITCH

‹4.3.1 ENGINE OIL RECOMMENDATIONS

4.2CHECKING THE ENGINE OIL LEVEL

4.3CHANGING THE ENGINE OIL

‹ 4.3.2 OIL CHANGE PROCEDURE

Figure 4.6 - 7 kW, Engine Air Cleaner Location

4.5CHANGING THE ENGINE AIR CLEANER

4.4CHANGING THE OIL FILTER

4.6SPARK PLUGS

4.7BATTERY MAINTENANCE

4.8ADJUSTING GH-410/GT-990VALVE CLEARANCE

Figure 4.8 - Setting the Spark Plug Gap

Figure 4.10 - Valve Clearance Adjustment

4.9COOLING SYSTEM

4.10 ATTENTION AFTER SUBMERSION

4.11 CORROSION PROTECTION

4.12 OUT OF SERVICE PROCEDURE

‹4.12.1 REMOVAL FROM SERVICE

‹4.12.2 RETURN TO SERVICE

4.13 SERVICE SCHEDULE

CORRECTION

5.1TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

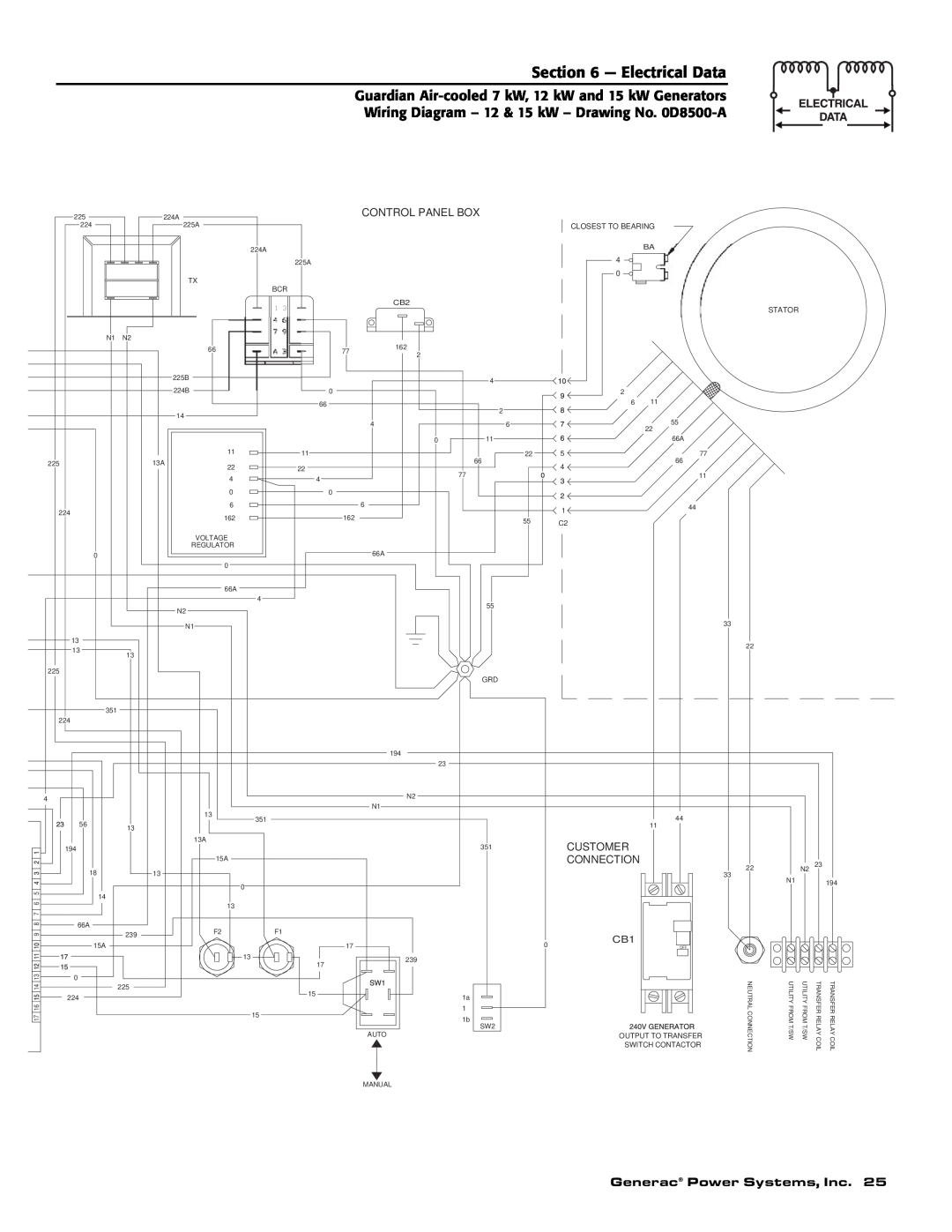

Section 6 - Electrical Data

24 Generac Power Systems, Inc

CONTROL PANEL BOX

CUSTOMER

CONNECTION

26 Generac Power Systems, Inc

C2-6

28 Generac Power Systems, Inc

Wiring Diagram - 7 kW - Drawing No. 0D9013-A

CLOSEST TO BEA 4 0 STATOR

CUSTOMER CONNECTION

30 Generac Power Systems, Inc

Generac Power Systems, Inc

32 Generac Power Systems, Inc

Section 7 - Exploded Views and Parts Lists

PART NO.QTY. DESCRIPTION

Control Panel - Drawing No. 0D8503-E

DESCRIPTION

Section 7 - Exploded Views and Parts Lists

0D4801

37 17 24

0D3086

Kit Contains

Section 7 - Exploded Views and Parts Lists

42 Generac Power Systems, Inc

Section 7 - Exploded Views and Parts Lists

44 Generac Power Systems, Inc

7 kW Generator - Drawing No. 0D3504-B

46 Generac Power Systems, Inc

12 kW and 15 kW Generator - Drawing No. 0D3417-B

48 Generac Power Systems, Inc

GN410 Engine - Drawing No. 0D3539-BPart

50 Generac Power Systems, Inc

0C1069

PART NO. QTY

NTAKE

Section 8 - Mounting Dimensions

TRANSFER SWITCH

Guardian Air

54 Generac Power Systems, Inc

Generac Power Systems, Inc

Section 10 - Warranty

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

PURCHASER’S/OWNER’S WARRANTY RESPONSIBILITIES

EMISSION RELATED PARTS INCLUDE THE FOLLOWING

EMISSION CONTROL SYSTEM WARRANTY

WARRANTY SCHEDULE

GENERAC POWER SYSTEMS, INC

P.O. BOX WHITEWATER, WI