Section 2 — Post Installation

Guardian

5.Turn the speed adjust nut to obtain a frequency reading of 63 Hz.

6.When frequency is correct at no load, check the AC voltage reading. If voltage is incorrect, the volt- age regulator may require adjustment.

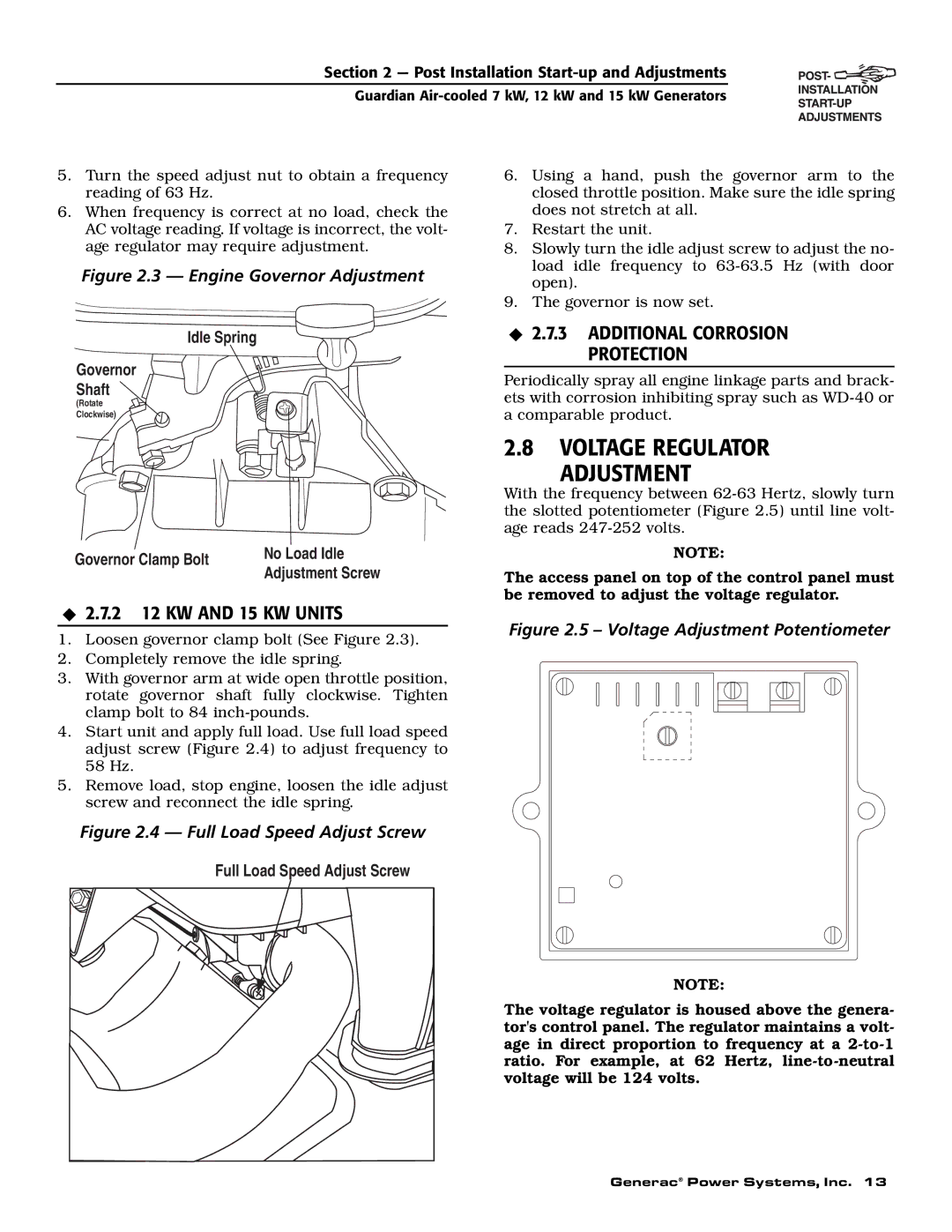

Figure 2.3 — Engine Governor Adjustment

Idle Spring

Governor

Shaft

(Rotate

Clockwise)

Governor Clamp Bolt | No Load Idle | |

Adjustment Screw | ||

|

6.Using a hand, push the governor arm to the closed throttle position. Make sure the idle spring does not stretch at all.

7.Restart the unit.

8.Slowly turn the idle adjust screw to adjust the no- load idle frequency to

9.The governor is now set.

◆2.7.3 ADDITIONAL CORROSION PROTECTION

Periodically spray all engine linkage parts and brack- ets with corrosion inhibiting spray such as

2.8VOLTAGE REGULATOR

ADJUSTMENT

With the frequency between

NOTE:

The access panel on top of the control panel must be removed to adjust the voltage regulator.

◆2.7.2 12 KW AND 15 KW UNITS

1.Loosen governor clamp bolt (See Figure 2.3).

2.Completely remove the idle spring.

3.With governor arm at wide open throttle position, rotate governor shaft fully clockwise. Tighten clamp bolt to 84

4.Start unit and apply full load. Use full load speed adjust screw (Figure 2.4) to adjust frequency to 58 Hz.

5.Remove load, stop engine, loosen the idle adjust screw and reconnect the idle spring.

Figure 2.4 — Full Load Speed Adjust Screw

Full Load Speed Adjust Screw

Figure 2.5 – Voltage Adjustment Potentiometer

NOTE:

The voltage regulator is housed above the genera- tor's control panel. The regulator maintains a volt- age in direct proportion to frequency at a

Generac® Power Systems, Inc. 13