MAINTENANCE PROCEDURES

DAILY MAINTENANCE

CHECK HYDRAULIC OIL LEVEL

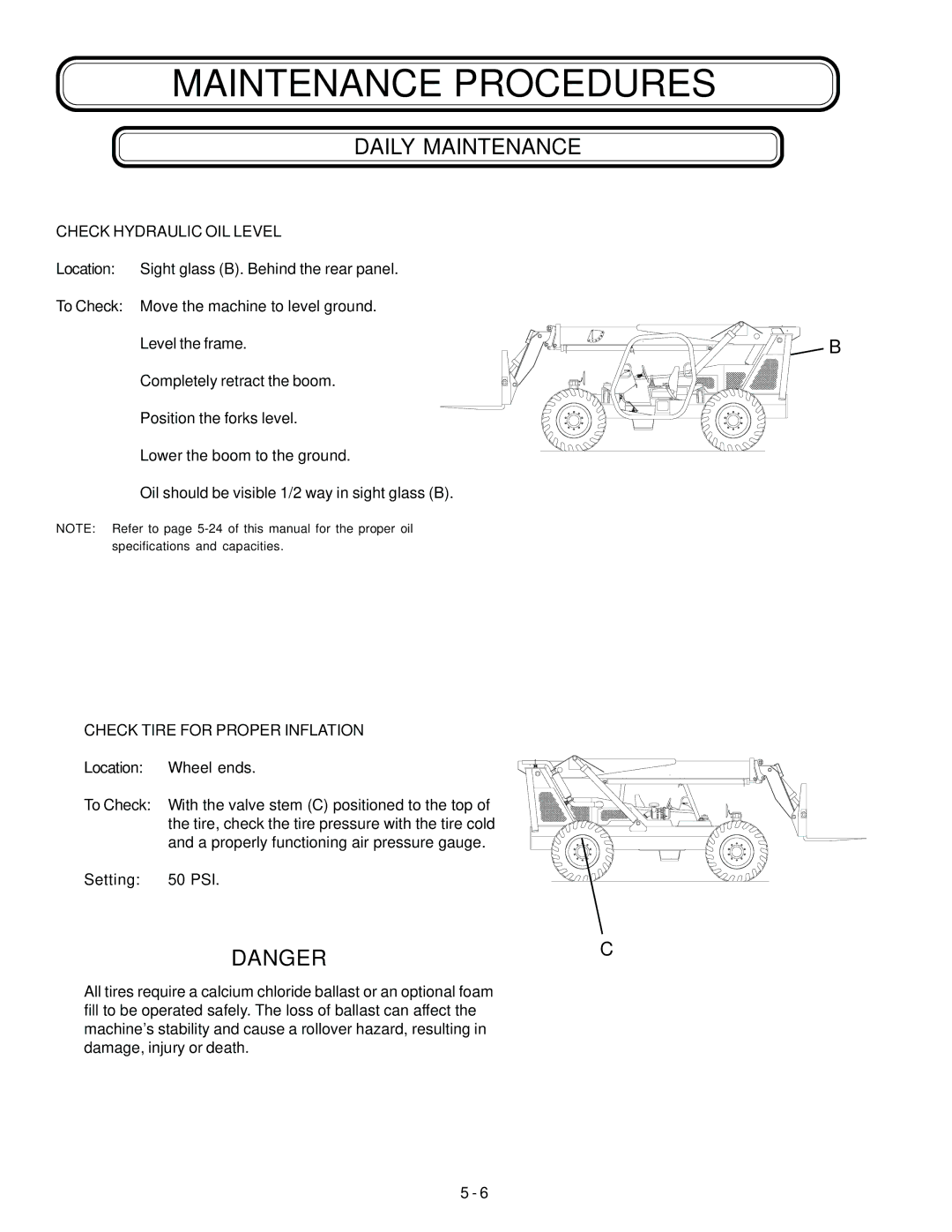

Location: Sight glass (B). Behind the rear panel.

To Check: Move the machine to level ground.

Level the frame.

Completely retract the boom.

Position the forks level.

Lower the boom to the ground.

Oil should be visible 1/2 way in sight glass (B).

NOTE: Refer to page

specifications and capacities.

CHECK TIRE FOR PROPER INFLATION

Location: Wheel ends.

To Check: With the valve stem (C) positioned to the top of the tire, check the tire pressure with the tire cold and a properly functioning air pressure gauge.

Setting: 50 PSI.

![]() DANGER

DANGER

All tires require a calcium chloride ballast or an optional foam fill to be operated safely. The loss of ballast can affect the machine's stability and cause a rollover hazard, resulting in damage, injury or death.

![]()

![]() B

B

C

5 - 6