7.For LP122A &

8.The

9.The front oil seal (31A) can now be removed by inserting a screwdriver through the rear of the retainer and tapping the seal out through the front of the retainer. Remove any ex- cess old

TO REASSEMBLE PROCEED AS FOLLOWS:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

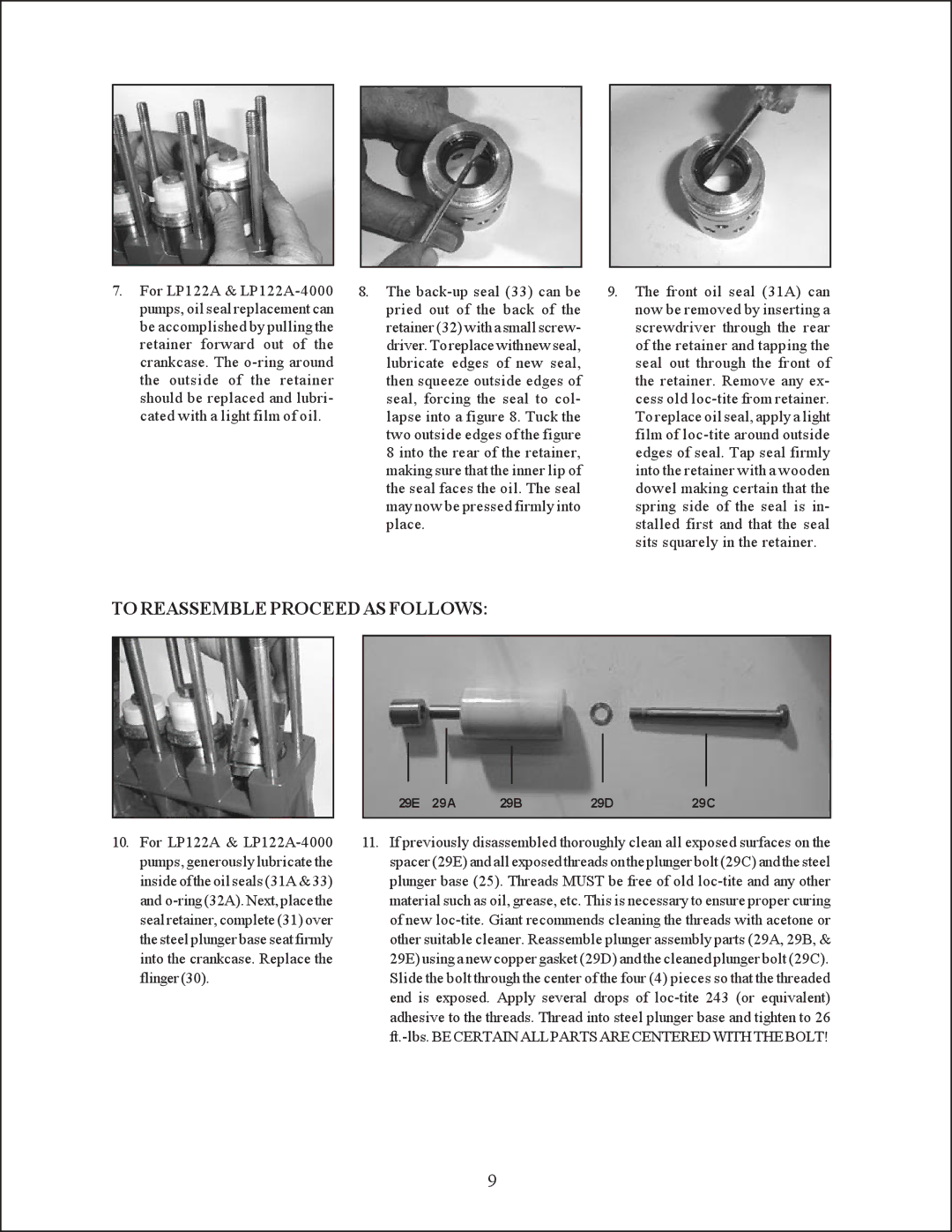

| 29E | 29A | 29B | 29D | 29C | |||||

|

|

|

|

|

|

|

| ||||

10. For LP122A & | 11. If previously disassembled thoroughly clean all exposed surfaces on the | ||||||||||

pumps, generously lubricate the |

| spacer (29E) and all exposed threads on the plunger bolt (29C) and the steel | |||||||||

inside of the oil seals (31A & 33) |

| plunger base (25). Threads MUST be free of old | |||||||||

and |

| material such as oil, grease, etc. This is necessary to ensure proper curing | |||||||||

seal retainer, complete (31) over |

| of new | |||||||||

the steel plunger base seat firmly |

| other suitable cleaner. Reassemble plunger assembly parts (29A, 29B, & | |||||||||

into the crankcase. Replace the |

| 29E) using a new copper gasket (29D) and the cleaned plunger bolt (29C). | |||||||||

flinger(30). |

| Slide the bolt through the center of the four (4) pieces so that the threaded | |||||||||

|

| end is exposed. Apply several drops of | |||||||||

|

| adhesive to the threads. Thread into steel plunger base and tighten to 26 | |||||||||

|

|

| |||||||||

9