REPAIR INSTRUCTIONS - P200A SERIES

NOTE: Always take time to lubricate all metal and nonmetal parts with a light film of oil before reassembly.

This step will ensure proper fit, at the same time protecting the pump nonmetal parts (i.e., the elastomers) from cutting and scoring.

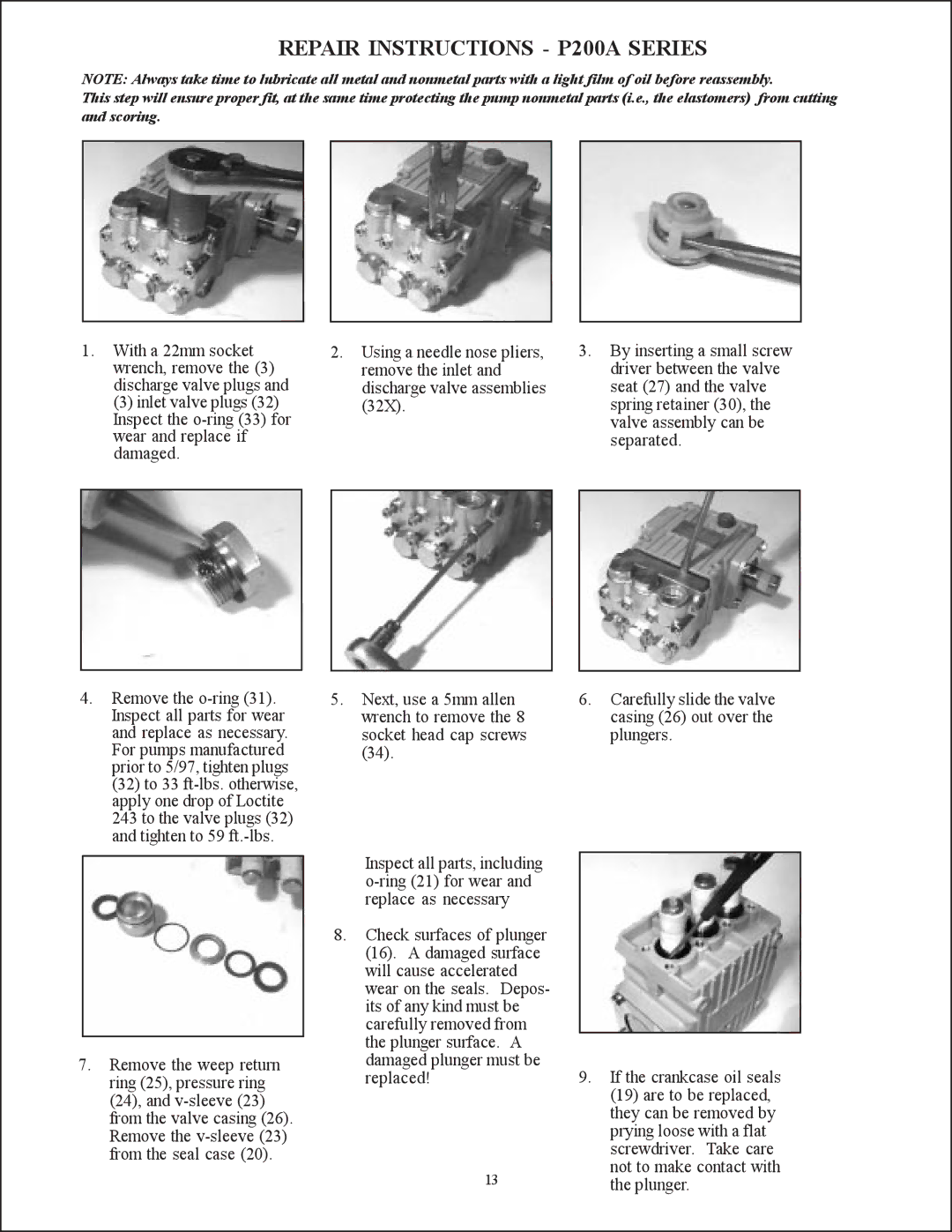

1.With a 22mm socket wrench, remove the (3) discharge valve plugs and

(3) inlet valve plugs (32) Inspect the

4.Remove the

7.Remove the weep return ring (25), pressure ring (24), and

2.Using a needle nose pliers, remove the inlet and discharge valve assemblies (32X).

5.Next, use a 5mm allen wrench to remove the 8 socket head cap screws (34).

Inspect all parts, including

8.Check surfaces of plunger (16). A damaged surface will cause accelerated wear on the seals. Depos- its of any kind must be carefully removed from the plunger surface. A damaged plunger must be replaced!

13

3.By inserting a small screw driver between the valve seat (27) and the valve spring retainer (30), the valve assembly can be separated.

6.Carefully slide the valve casing (26) out over the plungers.

9.If the crankcase oil seals (19) are to be replaced, they can be removed by prying loose with a flat screwdriver. Take care not to make contact with the plunger.