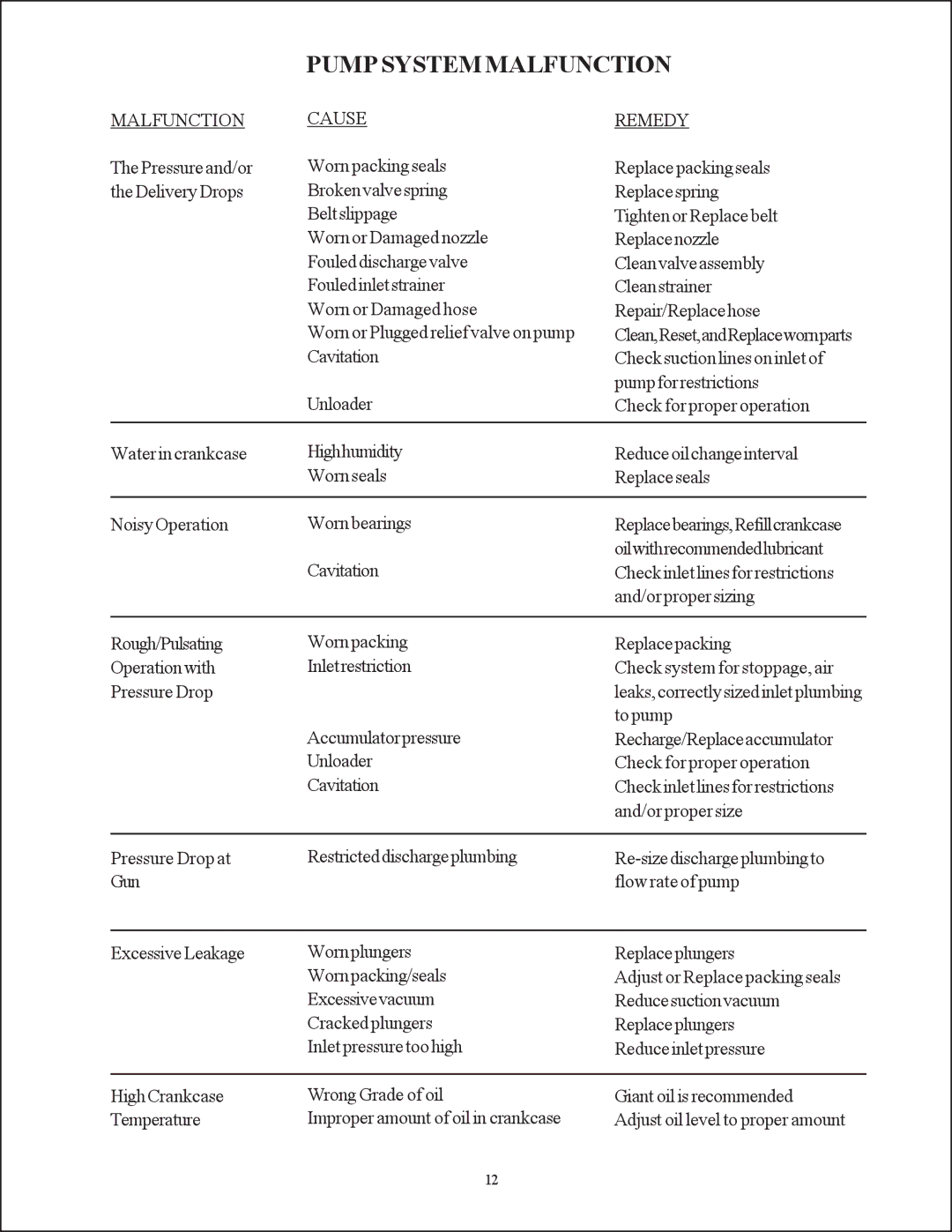

PUMPSYSTEMMALFUNCTION

MALFUNCTION | CAUSE | REMEDY |

The Pressure and/or | Worn packing seals | Replace packing seals |

theDeliveryDrops | Brokenvalvespring | Replacespring |

| Beltslippage | Tighten or Replace belt |

| Worn or Damaged nozzle | Replacenozzle |

| Fouleddischargevalve | Cleanvalveassembly |

| Fouledinletstrainer | Cleanstrainer |

| Worn or Damaged hose | Repair/Replacehose |

| Worn or Plugged relief valve on pump | Clean,Reset,andReplacewornparts |

| Cavitation | Check suction lines on inlet of |

|

| pumpforrestrictions |

| Unloader | Check for proper operation |

|

|

|

Water in crankcase | Highhumidity | Reduceoilchangeinterval |

| Worn seals | Replaceseals |

|

|

|

Noisy Operation Wornbearings

Cavitation

Replacebearings,Refillcrankcase oilwithrecommendedlubricant Checkinletlinesforrestrictions and/orproper sizing

Rough/Pulsating Wornpacking

Operationwith Inletrestriction

Pressure Drop

Accumulatorpressure

Unloader

Cavitation

Replacepacking

Check system for stoppage, air leaks,correctlysizedinletplumbing to pump

Recharge/Replaceaccumulator Check for proper operation Checkinletlinesforrestrictions and/or proper size

Pressure Drop at | Restricteddischargeplumbing | |

Gun |

| flow rate of pump |

|

|

|

ExcessiveLeakage | Wornplungers | Replaceplungers |

| Wornpacking/seals | Adjust or Replace packing seals |

| Excessivevacuum | Reducesuctionvacuum |

| Crackedplungers | Replaceplungers |

| Inlet pressure too high | Reduceinletpressure |

|

|

|

HighCrankcase | Wrong Grade of oil | Giant oil is recommended |

Temperature | Improper amount of oil in crankcase | Adjust oil level to proper amount |

12