WARNINGS.

1.Never attempt to remove any part of the compressor whilst the tank is under pressure.

2.Never attempt to remove any electrical component whilst the compressor is connected to the power supply. Switch off the power and remove the electrical plug.

3.Do not adjust the safety valve.

4.Do not use an electrical extension cable.

5.If the release valve under the pressure switch cover (2) fails to operate when the On/Off lever (3) is set in the off position, switch the power supply off and determine the nature of the fault.

6.Ensure that the lubricating oil is clean and that the oil level is maintained at the mid point of the red circle in the oil level glass (16).

7.Take care when discharging air from the tank, i.e. from the safety valve (8), the drain cock (10) or the air outlet (6). Compressed air can be extremely dangerous.

Take care; make sure that the discharge air does not cause dust, stones or any other foreign particles to be blown through the air and that the air is discharged in a safe manner.

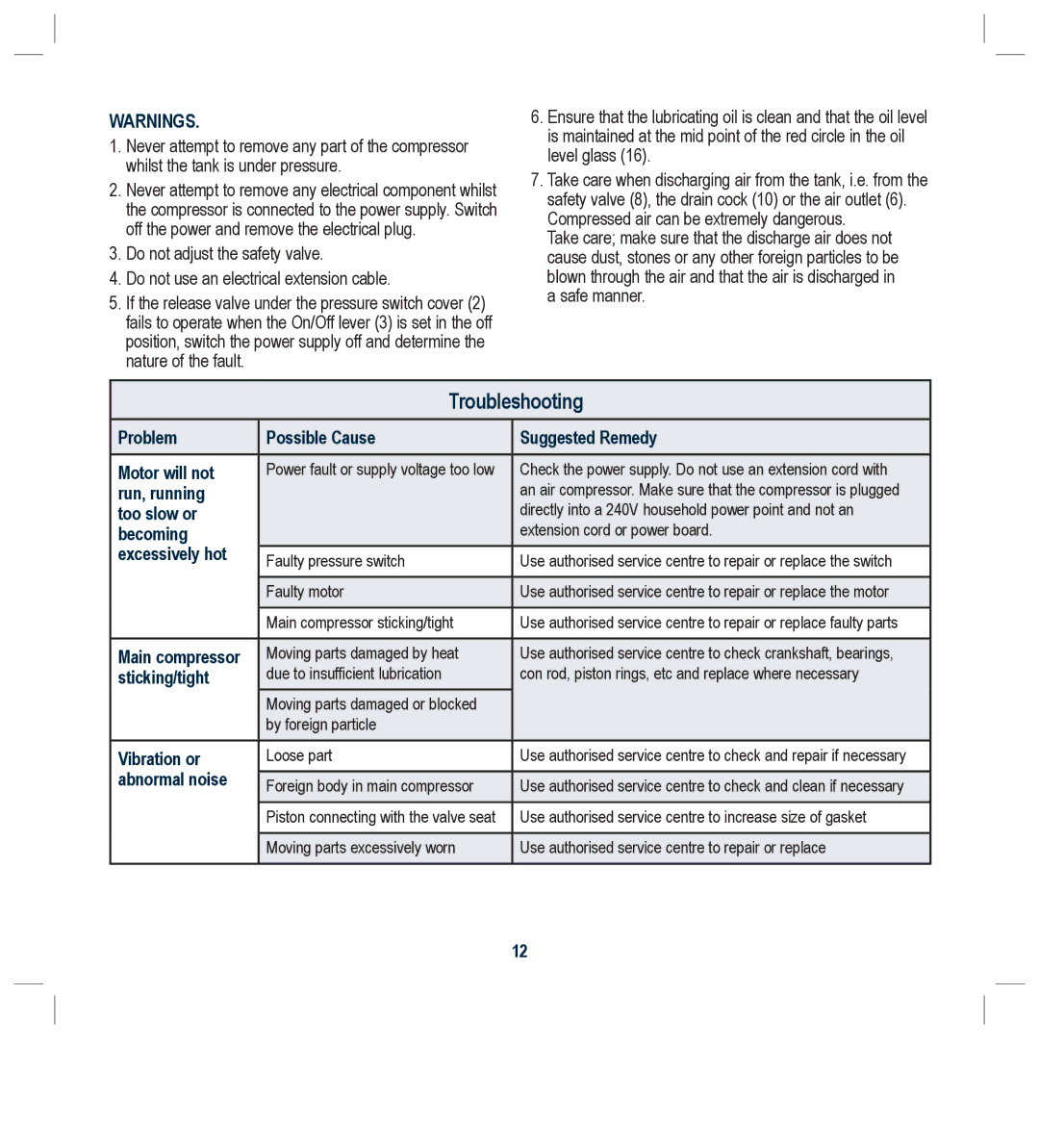

Troubleshooting

Problem | Possible Cause | Suggested Remedy |

|

|

|

Motor will not | Power fault or supply voltage too low | Check the power supply. Do not use an extension cord with |

run, running |

| an air compressor. Make sure that the compressor is plugged |

too slow or |

| directly into a 240V household power point and not an |

becoming |

| extension cord or power board. |

excessively hot | Faulty pressure switch | Use authorised service centre to repair or replace the switch |

| ||

|

|

|

| Faulty motor | Use authorised service centre to repair or replace the motor |

|

|

|

| Main compressor sticking/tight | Use authorised service centre to repair or replace faulty parts |

|

|

|

Main compressor | Moving parts damaged by heat | Use authorised service centre to check crankshaft, bearings, |

sticking/tight | due to insufficient lubrication | con rod, piston rings, etc and replace where necessary |

| Moving parts damaged or blocked |

|

| by foreign particle |

|

|

|

|

Vibration or | Loose part | Use authorised service centre to check and repair if necessary |

abnormal noise | Foreign body in main compressor | Use authorised service centre to check and clean if necessary |

| ||

|

|

|

| Piston connecting with the valve seat | Use authorised service centre to increase size of gasket |

|

|

|

| Moving parts excessively worn | Use authorised service centre to repair or replace |

|

|

|

12