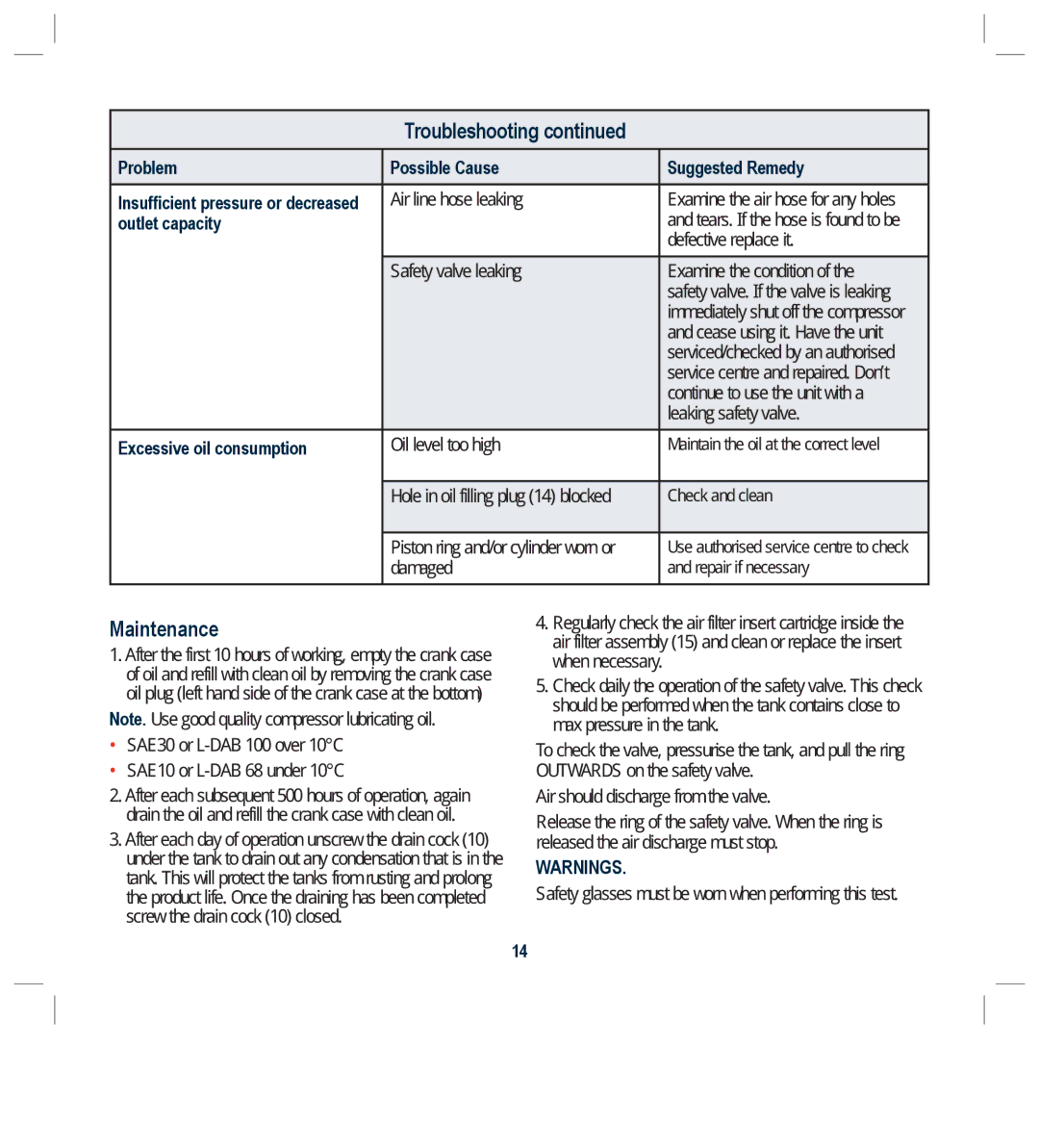

Troubleshooting continued

Problem | Possible Cause | Suggested Remedy |

|

|

|

Insufficient pressure or decreased | Air line hose leaking | Examine the air hose for any holes |

outlet capacity |

| and tears. If the hose is found to be |

|

| defective replace it. |

|

|

|

| Safety valve leaking | Examine the condition of the |

|

| safety valve. If the valve is leaking |

|

| immediately shut off the compressor |

|

| and cease using it. Have the unit |

|

| serviced/checked by an authorised |

|

| service centre and repaired. Don’t |

|

| continue to use the unit with a |

|

| leaking safety valve. |

|

|

|

Excessive oil consumption | Oil level too high | Maintain the oil at the correct level |

|

|

|

| Hole in oil filling plug (14) blocked | Check and clean |

|

|

|

| Piston ring and/or cylinder worn or | Use authorised service centre to check |

| damaged | and repair if necessary |

|

|

|

Maintenance

1.After the first 10 hours of working, empty the crank case of oil and refill with clean oil by removing the crank case oil plug (left hand side of the crank case at the bottom)

Note. Use good quality compressor lubricating oil.

•SAE30 or L-DAB 100 over 10°C

•SAE10 or L-DAB 68 under 10°C

2.After each subsequent 500 hours of operation, again drain the oil and refill the crank case with clean oil.

3.After each day of operation unscrew the drain cock (10) under the tank to drain out any condensation that is in the tank. This will protect the tanks from rusting and prolong the product life. Once the draining has been completed screw the drain cock (10) closed.

4.Regularly check the air filter insert cartridge inside the air filter assembly (15) and clean or replace the insert when necessary.

5.Check daily the operation of the safety valve. This check should be performed when the tank contains close to max pressure in the tank.

To check the valve, pressurise the tank, and pull the ring OUTWARDS on the safety valve.

Air should discharge from the valve.

Release the ring of the safety valve. When the ring is released the air discharge must stop.

WARNINGS.

Safety glasses must be worn when performing this test.

14