Setting up

| ||

1. Screw the |

| |

A | ||

auxiliary handle (8) into the | ||

most suitable mounting point |

| |

(5) (top, left side or right side) |

| |

to suit the planned operation. |

| |

(Fig. A) |

| |

2. Press the rotating handle |

| |

release button (10) and turn |

| |

the rotating handle (9) to suit |

| |

the planned operation. (Fig. B) | B | |

NOTE. The rear handle (9) can | ||

| ||

be rotated to the left or right. It |

| |

must be “locked” into one of the |

| |

three preset positions: central, |

| |

90° to the left or 90° to the |

| |

right. It must not be used at any |

| |

position in between these three |

| |

preset positions as it might rotate |

| |

during use and create a hazard. |

|

NOTE. Grinding operations normally require the angle grinder to be held with the grinding disc at an angle of 20° to 30° between the tool and the plane of the workpiece whilst cutting operations normally require the angle grinder to held with the cutting disc at right angles to the workpiece. Take the time to find the best combination of auxiliary handle and rotating handle positions to suit the task on hand. It can make a considerable difference to the levels of convenience and safety of operation.

Disc guard |

| |

C | ||

WARNING. Switch off the | ||

| ||

grinder and disconnect it from |

| |

the power point. |

| |

NOTE. Grinding operations |

| |

normally require the angle |

| |

grinder to be held with the |

| |

grinding disc parallel to the plane |

|

of the workpiece whilst cutting |

| |

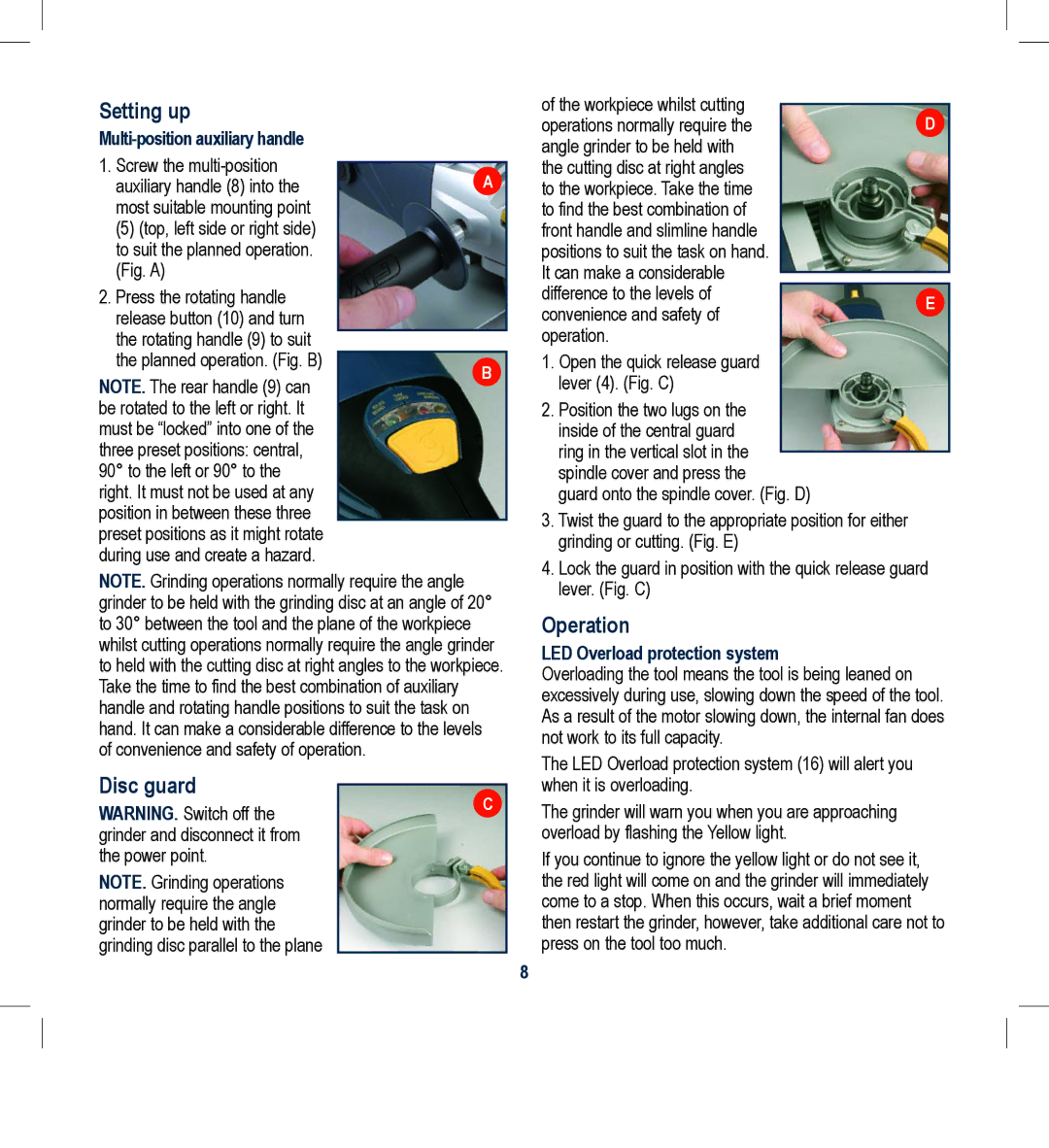

D | ||

operations normally require the | ||

angle grinder to be held with |

| |

the cutting disc at right angles |

| |

to the workpiece. Take the time |

| |

to find the best combination of |

| |

front handle and slimline handle |

| |

positions to suit the task on hand. |

| |

It can make a considerable |

| |

| ||

difference to the levels of | E | |

convenience and safety of | ||

| ||

operation. |

|

1.Open the quick release guard lever (4). (Fig. C)

2.Position the two lugs on the inside of the central guard ring in the vertical slot in the spindle cover and press the

guard onto the spindle cover. (Fig. D)

3.Twist the guard to the appropriate position for either grinding or cutting. (Fig. E)

4.Lock the guard in position with the quick release guard lever. (Fig. C)

Operation

LED Overload protection system

Overloading the tool means the tool is being leaned on excessively during use, slowing down the speed of the tool. As a result of the motor slowing down, the internal fan does not work to its full capacity.

The LED Overload protection system (16) will alert you when it is overloading.

The grinder will warn you when you are approaching overload by flashing the Yellow light.

If you continue to ignore the yellow light or do not see it, the red light will come on and the grinder will immediately come to a stop. When this occurs, wait a brief moment then restart the grinder, however, take additional care not to press on the tool too much.

8