4. Repeat for the two remaining blades.

CAUTION. When installing blades, first clean out all chips |

|

|

|

| |||||||

or foreign matter adhering to the blade barrel (10) and the |

|

|

|

| |||||||

blades themselves. Use blades of the same dimensions |

|

|

|

| |||||||

and weight, or the barrel will oscillate and vibrate causing | • Nicks in surface – as caused by the edge of one or all | ||||||||||

poor planing action and possibly a machine breakdown. | blades not being parallel to the surface of the rear base. | ||||||||||

Tighten the clamping screws (11) carefully when attaching |

|

|

|

| |||||||

the blades to the planer. A loose clamping screw could |

|

|

|

| |||||||

|

|

|

| ||||||||

be extremely dangerous. Regularly check to see they are |

|

|

|

| |||||||

tightened securely. |

|

|

|

|

|

| (a) | (b) | |||

CAUTION. The planer is designed so that the blades are |

|

|

| ||||||||

|

|

|

| ||||||||

correctly aligned if placed flush into the barrel slots and |

|

|

|

| |||||||

tightened correctly. |

|

|

|

|

| • Gouging at start – as caused by the edge of one or all | |||||

When inserting new blades it |

|

|

|

|

| ||||||

|

|

|

|

| blades not protruding enough in relation to the surface of | ||||||

| Blade must be | ||||||||||

is essential that they sit square |

| the rear base. |

| ||||||||

| positioned centrally |

| |||||||||

in their slot, that they are fully |

|

|

|

|

| ||||||

| on the drum |

|

|

|

| ||||||

inserted and that the cutting |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| |||

edges are absolutely level, |

|

|

|

|

|

| (a) |

| |||

i.e. parallel to the surface of |

|

|

|

|

|

| (b) | ||||

|

|

|

|

|

|

|

| ||||

the rear base. Only when all |

|

|

|

|

|

|

|

|

| ||

these conditions are satisfied |

|

|

|

|

|

|

|

|

| ||

should the clamping screws be |

|

|

|

|

| • Gouging at end – as caused by the edge of one or all | |||||

tightened. If the blades protrude |

|

|

|

|

| ||||||

|

|

|

|

| blades protruding too far in relation to the surface of the | ||||||

or are not square, they could hit the casing with serious risk | |||||||||||

rear base. |

| ||||||||||

to the operator and others in the vicinity. |

| ||||||||||

(A) front base (moveable shoe) |

| ||||||||||

Note. Your planing surface will end up rough and uneven |

| ||||||||||

(B) rear base (stationary shoe) |

| ||||||||||

unless the blades are set and secured properly. |

| ||||||||||

|

|

|

| ||||||||

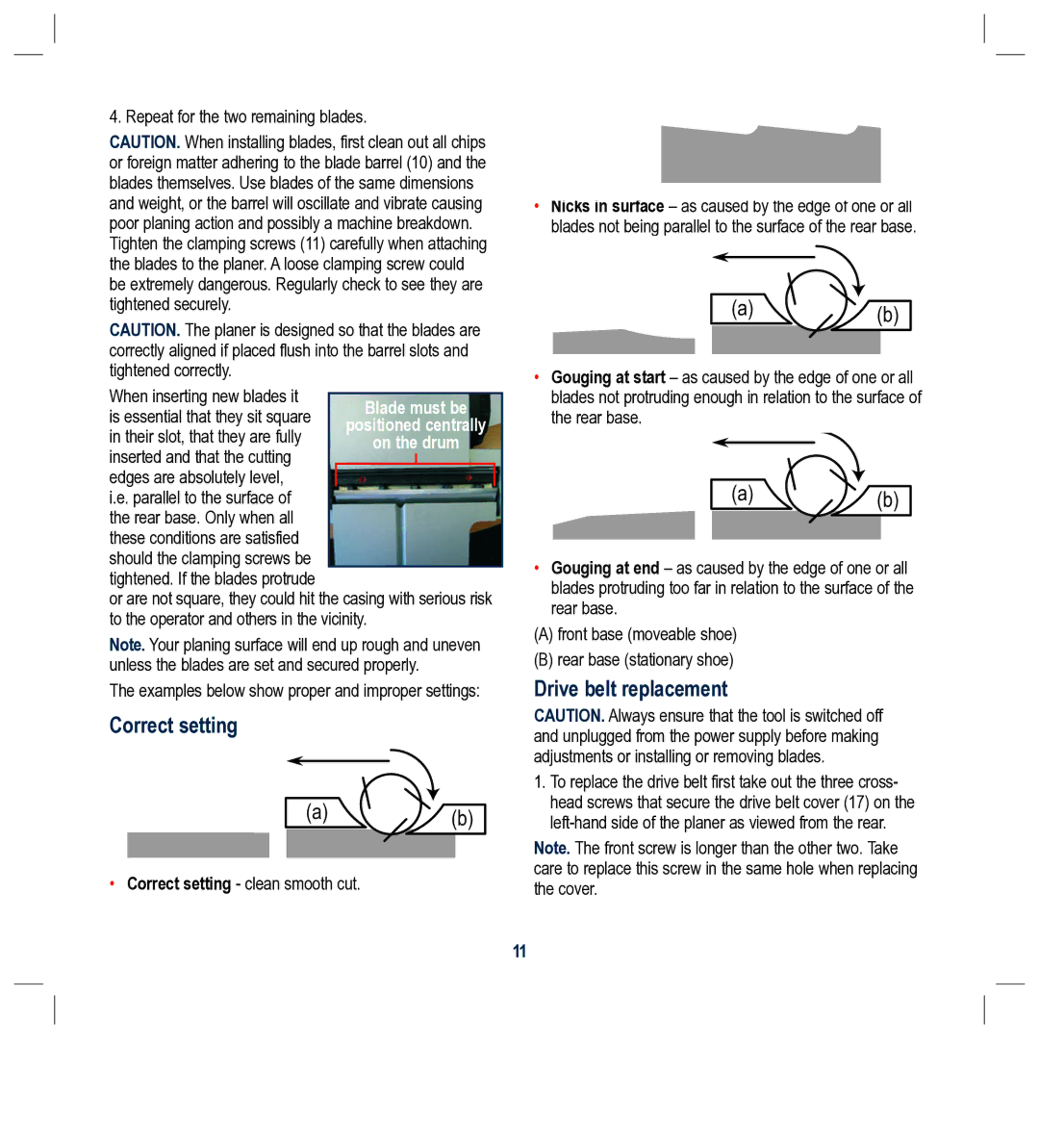

The examples below show proper and improper settings: | Drive belt replacement |

| |||||||||

Correct setting |

|

|

|

|

| CAUTION. Always ensure that the tool is switched off | |||||

|

|

|

|

| and unplugged from the power supply before making | ||||||

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| adjustments or installing or removing blades. |

| |||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

| 1. To replace the drive belt first take out the three cross- | ||||

| (a) |

|

|

| (b) | head screws that secure the drive belt cover (17) on the | |||||

|

|

|

| ||||||||

|

|

|

|

| |||||||

|

|

|

|

|

|

| Note. The front screw is longer than the other two. Take | ||||

• Correct setting - clean smooth cut. | care to replace this screw in the same hole when replacing | ||||||||||

the cover. |

| ||||||||||

11