Caution. During use it is important not to overload the grinder. The grinder should run at close to full speed. If you are applying too much pressure the grinder will start to slow down. Under these conditions, remove the part being ground and allow the grinder to return to full speed.

All of the grinding wheels are supplied with grinding wheels designed for metal use only. The grinding of Copper, Brass, Aluminium, Wood or other similar materials will “clog” the grinding wheel.

Warning. Never attempt to grind Magnesium.

Fitting and adjusting the eye shields and brackets.

Important. Prior to fitting the eye shield brackets, ensure the grinder is turned off and the power plug is removed from the socket.

Note. Always check to ensure the eye shields (1) are correctly fitted and the eye shield brackets (9) are correctly adjusted each time the grinder is used. Eye shields and brackets must be fitted over each grinding wheel on all the bench grinders in the range, except the sharpening wheel (11) on Model NTS2000A.

1.Remove the top screw of the wheel guard (8).

2.Fit the eye shield bracket (9).

3.Fit a flat steel washer on to the wheel guard screw and then pass the screw through the eye shield bracket, guard and then the eye shield bracket again. Fit another flat washer,

followed by the spring washer and then the nut. Tighten the nut so the bracket can slide.

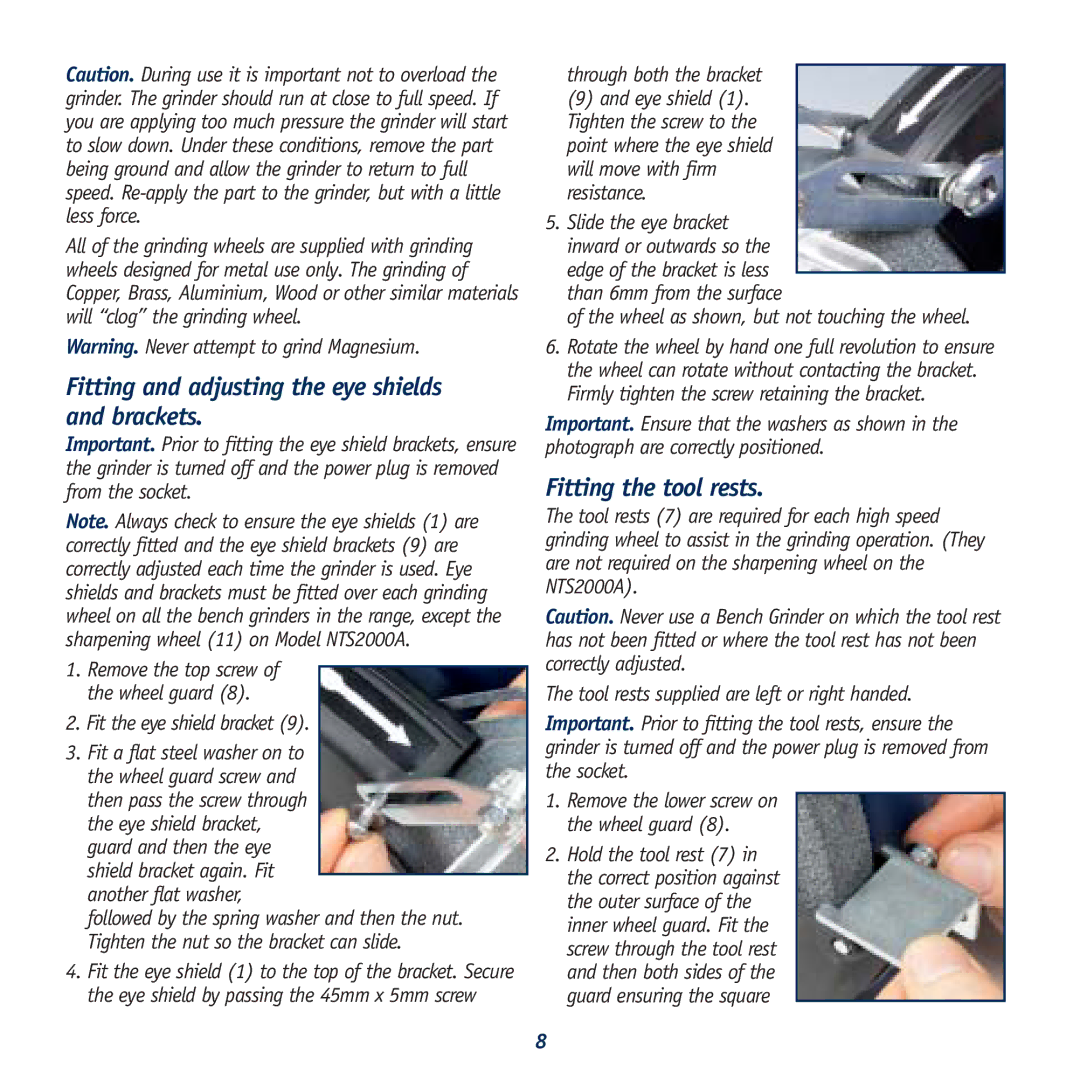

4.Fit the eye shield (1) to the top of the bracket. Secure the eye shield by passing the 45mm x 5mm screw

through both the bracket

(9) and eye shield (1). Tighten the screw to the point where the eye shield will move with firm resistance.

5.Slide the eye bracket inward or outwards so the edge of the bracket is less than 6mm from the surface

of the wheel as shown, but not touching the wheel.

6.Rotate the wheel by hand one full revolution to ensure the wheel can rotate without contacting the bracket. Firmly tighten the screw retaining the bracket.

Important. Ensure that the washers as shown in the photograph are correctly positioned.

Fitting the tool rests.

The tool rests (7) are required for each high speed grinding wheel to assist in the grinding operation. (They are not required on the sharpening wheel on the NTS2000A).

Caution. Never use a Bench Grinder on which the tool rest has not been fitted or where the tool rest has not been correctly adjusted.

The tool rests supplied are left or right handed.

Important. Prior to fitting the tool rests, ensure the grinder is turned off and the power plug is removed from the socket.

1.Remove the lower screw on the wheel guard (8).

2.Hold the tool rest (7) in the correct position against the outer surface of the inner wheel guard. Fit the screw through the tool rest and then both sides of the guard ensuring the square

8