6.Clean any grinding dust from the inner flange and, after checking that it is in good condition, mount a new disc between two paper blotters. The rear blotter should be mounted onto the inner flange and the front blotter is the printed surface on the front of the disc.

7.Replace the outer flange, washer and lock bolt. Tighten the bolt in a clockwise direction.

8.Turn the new disc by hand, ensuring that it rotates fully and does not wobble unduly.

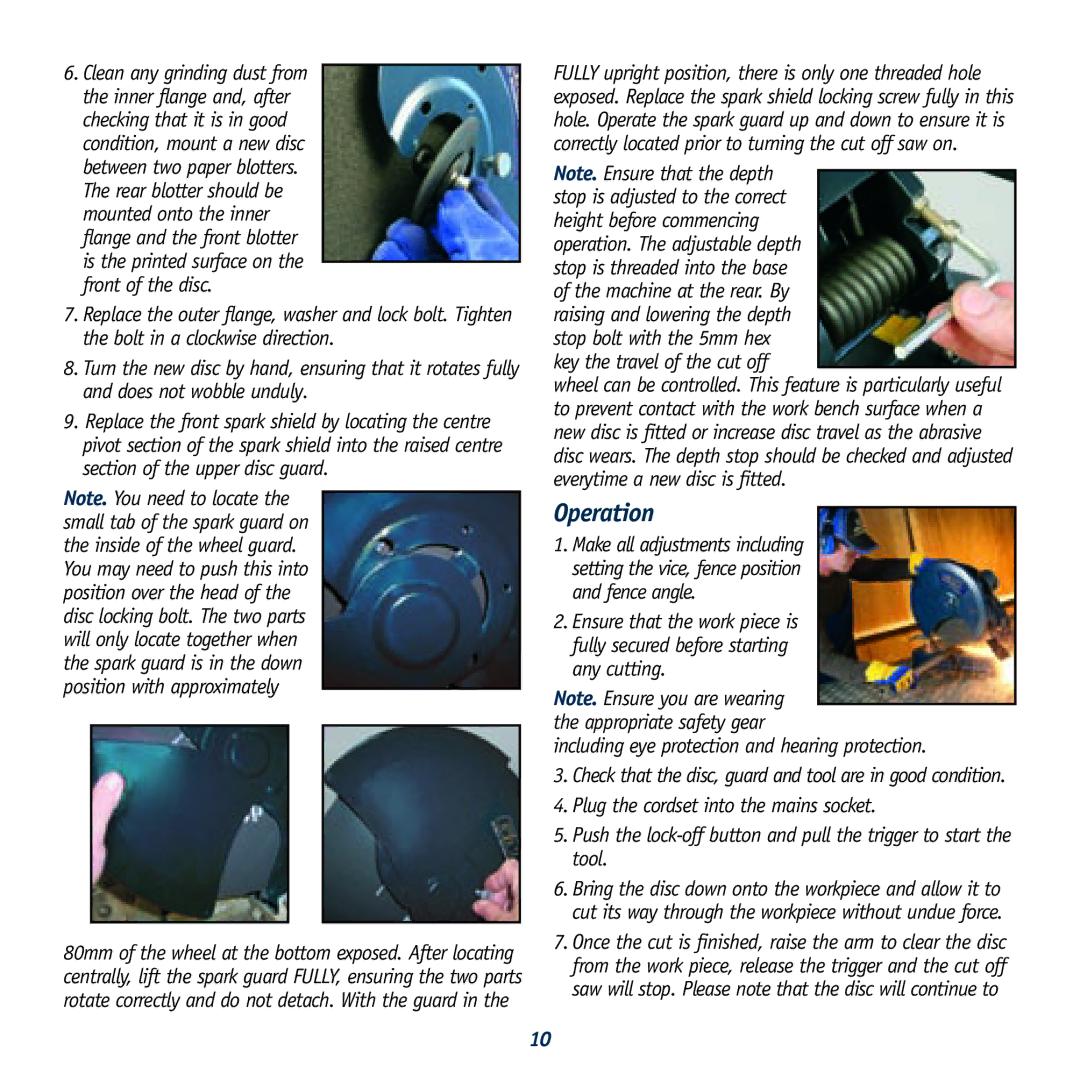

9.Replace the front spark shield by locating the centre pivot section of the spark shield into the raised centre section of the upper disc guard.

Note. You need to locate the small tab of the spark guard on the inside of the wheel guard. You may need to push this into position over the head of the disc locking bolt. The two parts will only locate together when the spark guard is in the down position with approximately

80mm of the wheel at the bottom exposed. After locating centrally, lift the spark guard FULLY, ensuring the two parts rotate correctly and do not detach. With the guard in the

FULLY upright position, there is only one threaded hole exposed. Replace the spark shield locking screw fully in this hole. Operate the spark guard up and down to ensure it is correctly located prior to turning the cut off saw on.

Note. Ensure that the depth stop is adjusted to the correct height before commencing operation. The adjustable depth stop is threaded into the base of the machine at the rear. By raising and lowering the depth stop bolt with the 5mm hex key the travel of the cut off

wheel can be controlled. This feature is particularly useful to prevent contact with the work bench surface when a new disc is fitted or increase disc travel as the abrasive disc wears. The depth stop should be checked and adjusted everytime a new disc is fitted.

Operation

1.Make all adjustments including setting the vice, fence position and fence angle.

2.Ensure that the work piece is fully secured before starting any cutting.

Note. Ensure you are wearing the appropriate safety gear

including eye protection and hearing protection.

3.Check that the disc, guard and tool are in good condition.

4.Plug the cordset into the mains socket.

5.Push the

6.Bring the disc down onto the workpiece and allow it to cut its way through the workpiece without undue force.

7.Once the cut is finished, raise the arm to clear the disc from the work piece, release the trigger and the cut off saw will stop. Please note that the disc will continue to

10