Inserting and removing bits

The drill is fitted with auto spindle lock which means if you try and rotate the chuck by hand the spindle of the drill will automatically lock. This means you only need to grasp the chuck and rotate the chuck housing to remove or fit accessories.

This drill has a keyless chuck, hence a chuck key is not needed to secure a bit in the drill. Always set the forward/ reverse switch (4) to the locked ‘OFF’ position when installing and removing bits. It is also recommended to remove the battery pack to avoid unintentional starting.

1.Open the chuck jaws by firmly holding the chuck housing and rotating the

housing in an

2.Ensure the accessory is fully inserted, so that the jaws of the chuck grip onto the flat section of the accessory.

3.To firmly clamp the accessory in the chuck, grasp the chuck housing and rotate the chuck housing in a clockwise direction. Ensure the bit is retained firmly or damage to the chuck jaws can result.

4.To remove the accessory, open the chuck jaws by firmly holding the chuck housing and rotating the housing in an anti clockwise direction. Open the jaws sufficiently so as to remove the specific accessory.

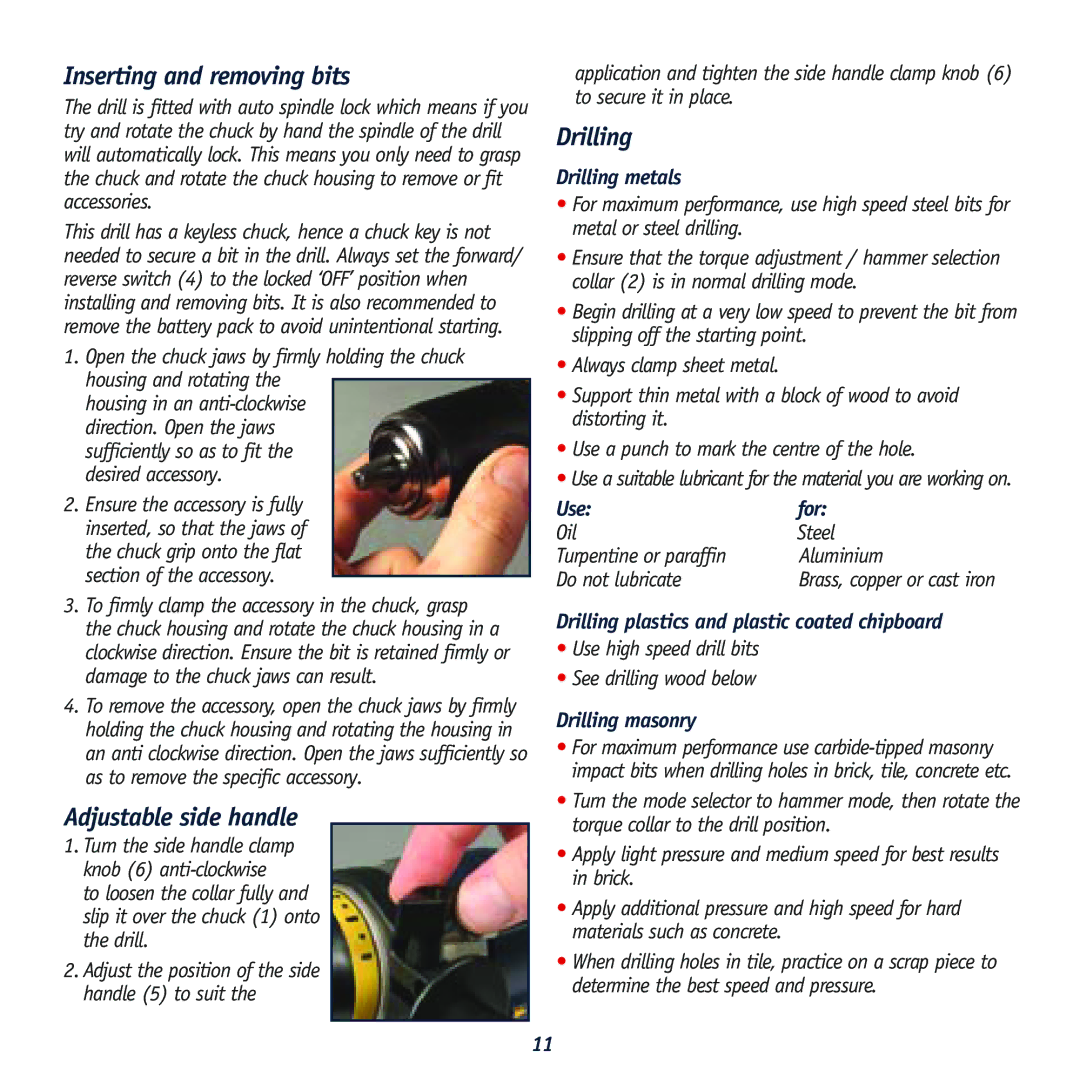

Adjustable side handle

1.Turn the side handle clamp knob (6)

to loosen the collar fully and slip it over the chuck (1) onto the drill.

2.Adjust the position of the side handle (5) to suit the

application and tighten the side handle clamp knob (6) to secure it in place.

Drilling

Drilling metals

•For maximum performance, use high speed steel bits for metal or steel drilling.

•Ensure that the torque adjustment / hammer selection collar (2) is in normal drilling mode.

•Begin drilling at a very low speed to prevent the bit from slipping off the starting point.

•Always clamp sheet metal.

•Support thin metal with a block of wood to avoid distorting it.

•Use a punch to mark the centre of the hole.

•Use a suitable lubricant for the material you are working on.

Use: | for: |

Oil | Steel |

Turpentine or paraffin | Aluminium |

Do not lubricate | Brass, copper or cast iron |

Drilling plastics and plastic coated chipboard

•Use high speed drill bits

•See drilling wood below

Drilling masonry

•For maximum performance use

•Turn the mode selector to hammer mode, then rotate the torque collar to the drill position.

•Apply light pressure and medium speed for best results in brick.

•Apply additional pressure and high speed for hard materials such as concrete.

•When drilling holes in tile, practice on a scrap piece to determine the best speed and pressure.

11