3.Determine the optimum speed by making a trial cut in a scrap piece of material.

NOTE. Using the correct speed for the job increases the life of the bit.

Making a cut

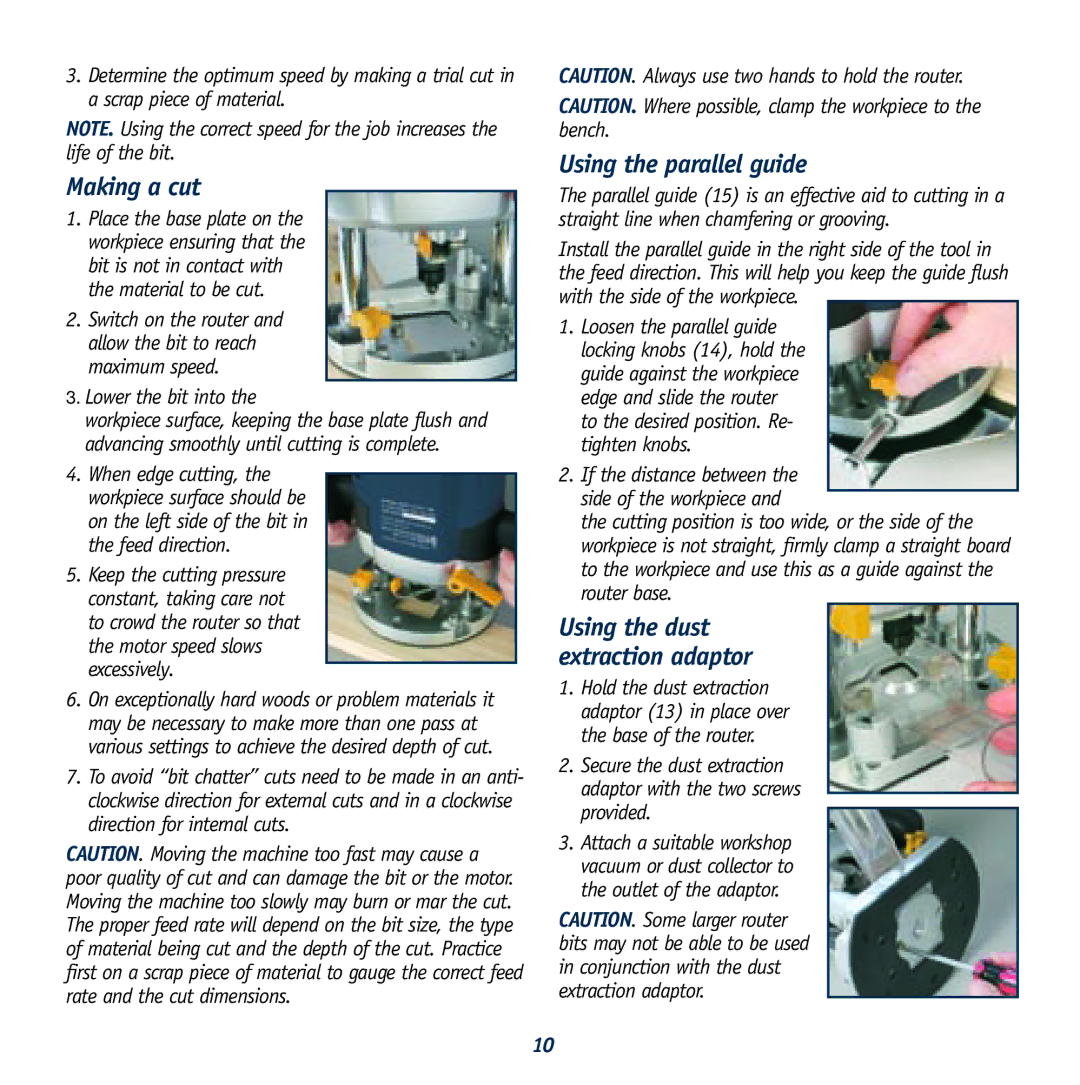

1.Place the base plate on the workpiece ensuring that the bit is not in contact with the material to be cut.

2.Switch on the router and allow the bit to reach maximum speed.

3.Lower the bit into the

workpiece surface, keeping the base plate flush and advancing smoothly until cutting is complete.

4.When edge cutting, the workpiece surface should be on the left side of the bit in the feed direction.

5.Keep the cutting pressure constant, taking care not to crowd the router so that the motor speed slows excessively.

6.On exceptionally hard woods or problem materials it may be necessary to make more than one pass at various settings to achieve the desired depth of cut.

7.To avoid “bit chatter” cuts need to be made in an anti- clockwise direction for external cuts and in a clockwise direction for internal cuts.

CAUTION. Moving the machine too fast may cause a poor quality of cut and can damage the bit or the motor. Moving the machine too slowly may burn or mar the cut. The proper feed rate will depend on the bit size, the type of material being cut and the depth of the cut. Practice first on a scrap piece of material to gauge the correct feed rate and the cut dimensions.

CAUTION. Always use two hands to hold the router.

CAUTION. Where possible, clamp the workpiece to the bench.

Using the parallel guide

The parallel guide (15) is an effective aid to cutting in a straight line when chamfering or grooving.

Install the parallel guide in the right side of the tool in the feed direction. This will help you keep the guide flush with the side of the workpiece.

1.Loosen the parallel guide locking knobs (14), hold the guide against the workpiece edge and slide the router to the desired position. Re- tighten knobs.

2.If the distance between the side of the workpiece and

the cutting position is too wide, or the side of the workpiece is not straight, firmly clamp a straight board to the workpiece and use this as a guide against the router base.

Using the dust extraction adaptor

1.Hold the dust extraction adaptor (13) in place over the base of the router.

2.Secure the dust extraction adaptor with the two screws provided.

3.Attach a suitable workshop vacuum or dust collector to the outlet of the adaptor.

CAUTION. Some larger router bits may not be able to be used in conjunction with the dust extraction adaptor.

10