WARNING. Do not tighten the collet nut without a bit in place or you may break the collet.

Adjusting the cutting depth

CAUTION. Always ensure that the router is switched off and unplugged from the mains supply before adjusting the depth of cut.

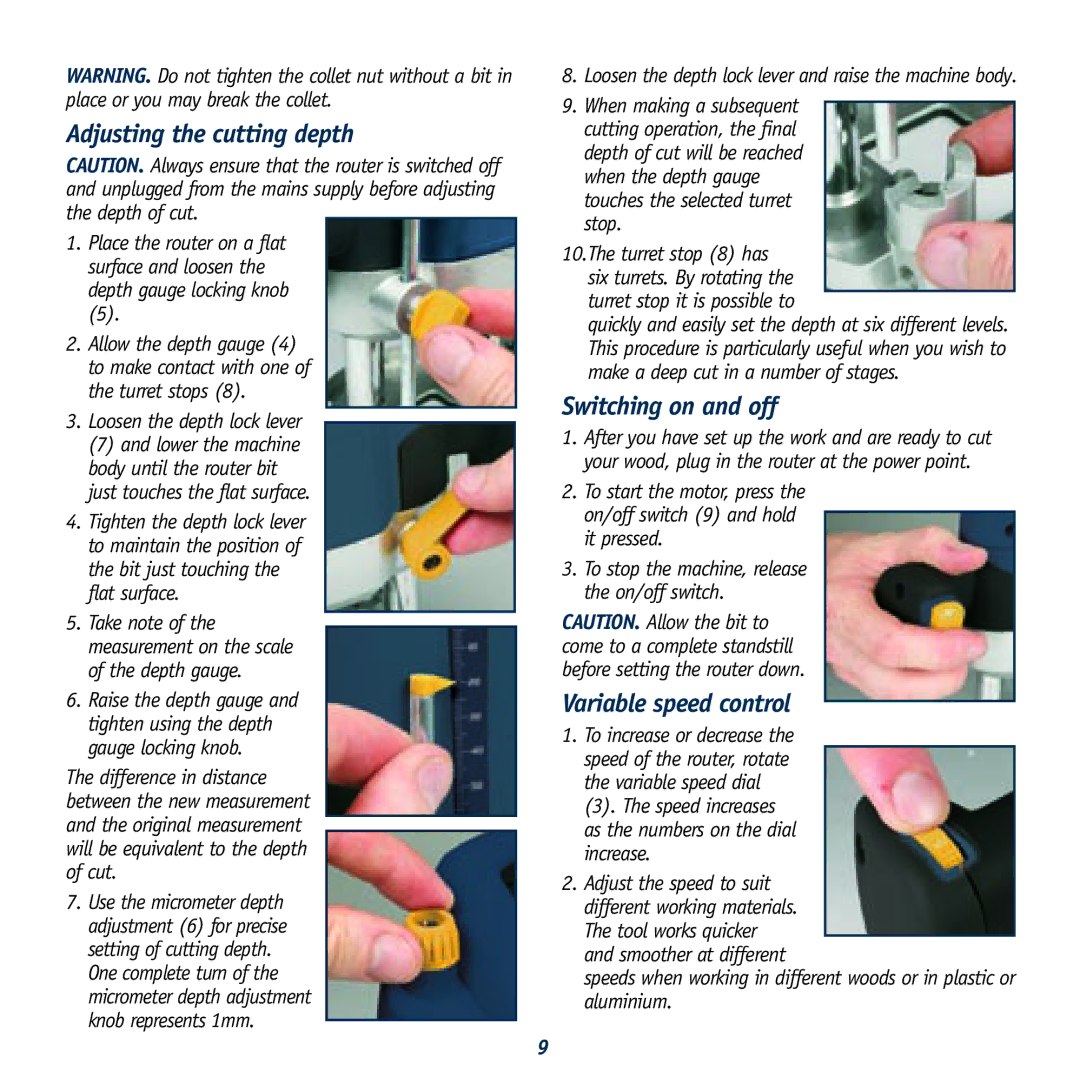

1.Place the router on a flat surface and loosen the depth gauge locking knob

(5).

2. Allow the depth gauge (4) to make contact with one of the turret stops (8).

3.Loosen the depth lock lever

(7) and lower the machine body until the router bit just touches the flat surface.

4.Tighten the depth lock lever to maintain the position of the bit just touching the flat surface.

5. Take note of the measurement on the scale of the depth gauge.

6.Raise the depth gauge and tighten using the depth gauge locking knob.

The difference in distance between the new measurement and the original measurement will be equivalent to the depth of cut.

7.Use the micrometer depth adjustment (6) for precise setting of cutting depth.

One complete turn of the micrometer depth adjustment knob represents 1mm.

8.Loosen the depth lock lever and raise the machine body.

9.When making a subsequent cutting operation, the final depth of cut will be reached when the depth gauge touches the selected turret stop.

10.The turret stop (8) has six turrets. By rotating the turret stop it is possible to

quickly and easily set the depth at six different levels. This procedure is particularly useful when you wish to make a deep cut in a number of stages.

Switching on and off

1.After you have set up the work and are ready to cut your wood, plug in the router at the power point.

2.To start the motor, press the on/off switch (9) and hold it pressed.

3.To stop the machine, release the on/off switch.

CAUTION. Allow the bit to come to a complete standstill before setting the router down.

Variable speed control

1.To increase or decrease the speed of the router, rotate the variable speed dial

(3). The speed increases as the numbers on the dial increase.

2.Adjust the speed to suit different working materials. The tool works quicker and smoother at different

speeds when working in different woods or in plastic or aluminium.

9