Installation

Grounding

The equipment must be grounded to reduce the risk of static sparking and electric shock. Electric or static sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock. Grounding provides an escape wire for the electric current.

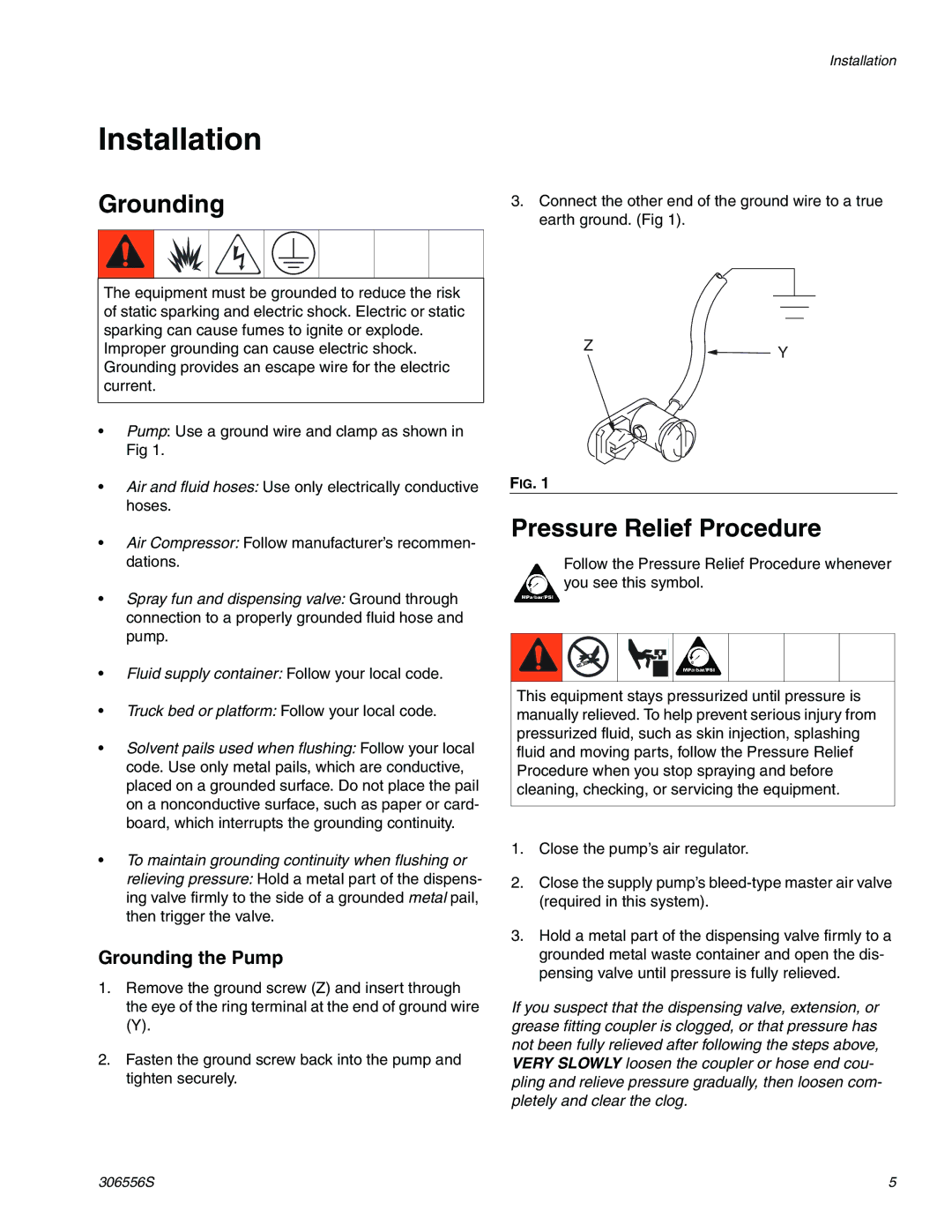

•Pump: Use a ground wire and clamp as shown in Fig 1.

•Air and fluid hoses: Use only electrically conductive hoses.

•Air Compressor: Follow manufacturer’s recommen- dations.

•Spray fun and dispensing valve: Ground through connection to a properly grounded fluid hose and pump.

•Fluid supply container: Follow your local code.

•Truck bed or platform: Follow your local code.

•Solvent pails used when flushing: Follow your local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not place the pail on a nonconductive surface, such as paper or card- board, which interrupts the grounding continuity.

•To maintain grounding continuity when flushing or relieving pressure: Hold a metal part of the dispens- ing valve firmly to the side of a grounded metal pail, then trigger the valve.

Grounding the Pump

1.Remove the ground screw (Z) and insert through the eye of the ring terminal at the end of ground wire

(Y).

2.Fasten the ground screw back into the pump and tighten securely.

Installation

3.Connect the other end of the ground wire to a true earth ground. (Fig 1).

Z![]() Y

Y

FIG. 1

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever you see this symbol.

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

1.Close the pump’s air regulator.

2.Close the supply pump’s

3.Hold a metal part of the dispensing valve firmly to a grounded metal waste container and open the dis- pensing valve until pressure is fully relieved.

If you suspect that the dispensing valve, extension, or grease fitting coupler is clogged, or that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen the coupler or hose end cou- pling and relieve pressure gradually, then loosen com- pletely and clear the clog.

306556S | 5 |