Air Motor and Throat Service

L 2

37 20 38

1

M![]()

26

31*

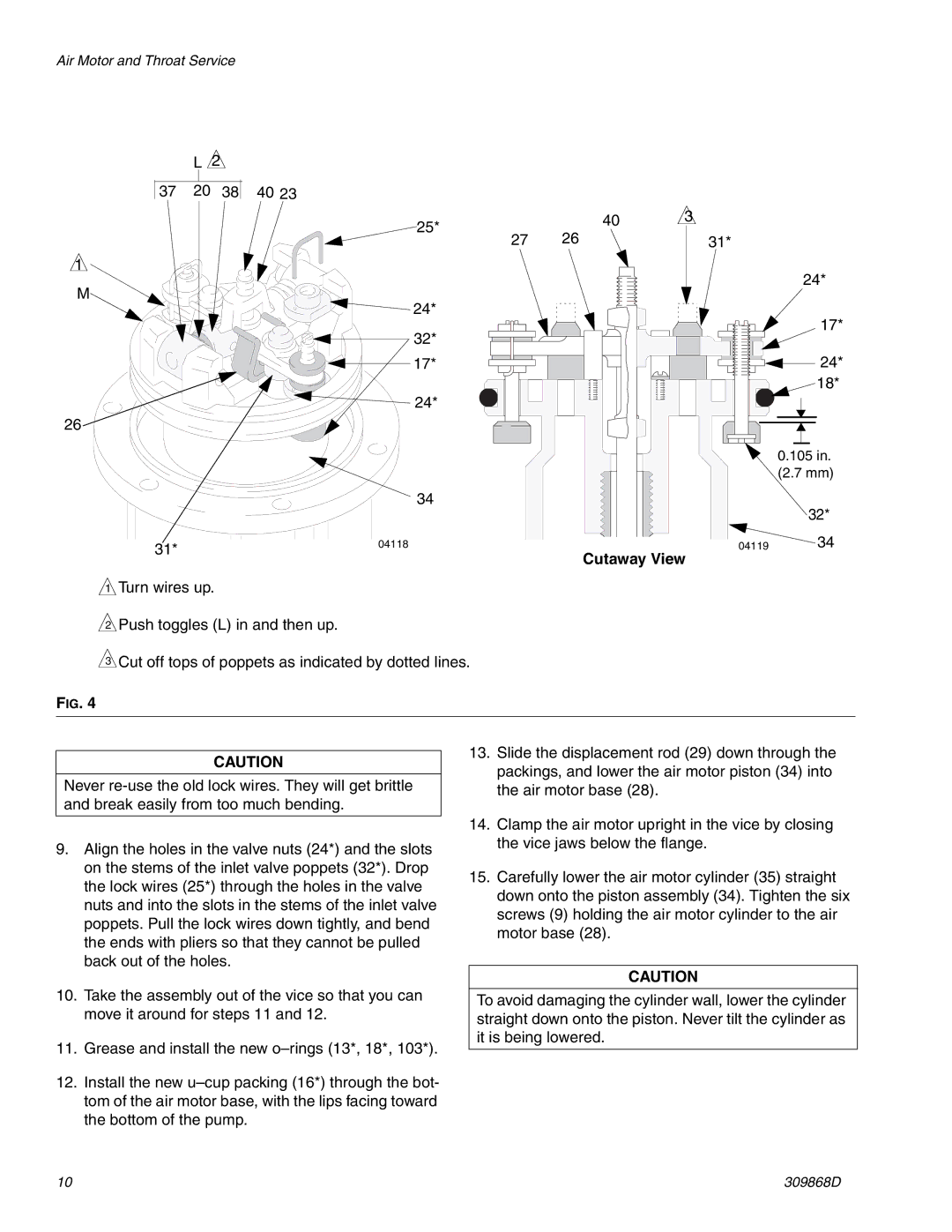

1Turn wires up.

40 23

![]() 25*

25*

![]() 24*

24*

32*

17*

![]() 24*

24*

34

04118

40 3

27 | 26 | 31* |

24*

17*

24*

![]() 18*

18*

0.105 in.

(2.7 mm)

32*

04119 34

Cutaway View

2Push toggles (L) in and then up.

3Cut off tops of poppets as indicated by dotted lines.

FIG. 4

CAUTION

Never

9.Align the holes in the valve nuts (24*) and the slots on the stems of the inlet valve poppets (32*). Drop the lock wires (25*) through the holes in the valve nuts and into the slots in the stems of the inlet valve poppets. Pull the lock wires down tightly, and bend the ends with pliers so that they cannot be pulled back out of the holes.

10.Take the assembly out of the vice so that you can move it around for steps 11 and 12.

11.Grease and install the new

12.Install the new

13.Slide the displacement rod (29) down through the packings, and lower the air motor piston (34) into the air motor base (28).

14.Clamp the air motor upright in the vice by closing the vice jaws below the flange.

15.Carefully lower the air motor cylinder (35) straight down onto the piston assembly (34). Tighten the six screws (9) holding the air motor cylinder to the air motor base (28).

CAUTION

To avoid damaging the cylinder wall, lower the cylinder straight down onto the piston. Never tilt the cylinder as it is being lowered.

10 | 309868D |