Repair

Clean Injection Slots

1.Perform Pressure Relief Procedure (page 13) and Clean Spray Gun Procedure, page 18.

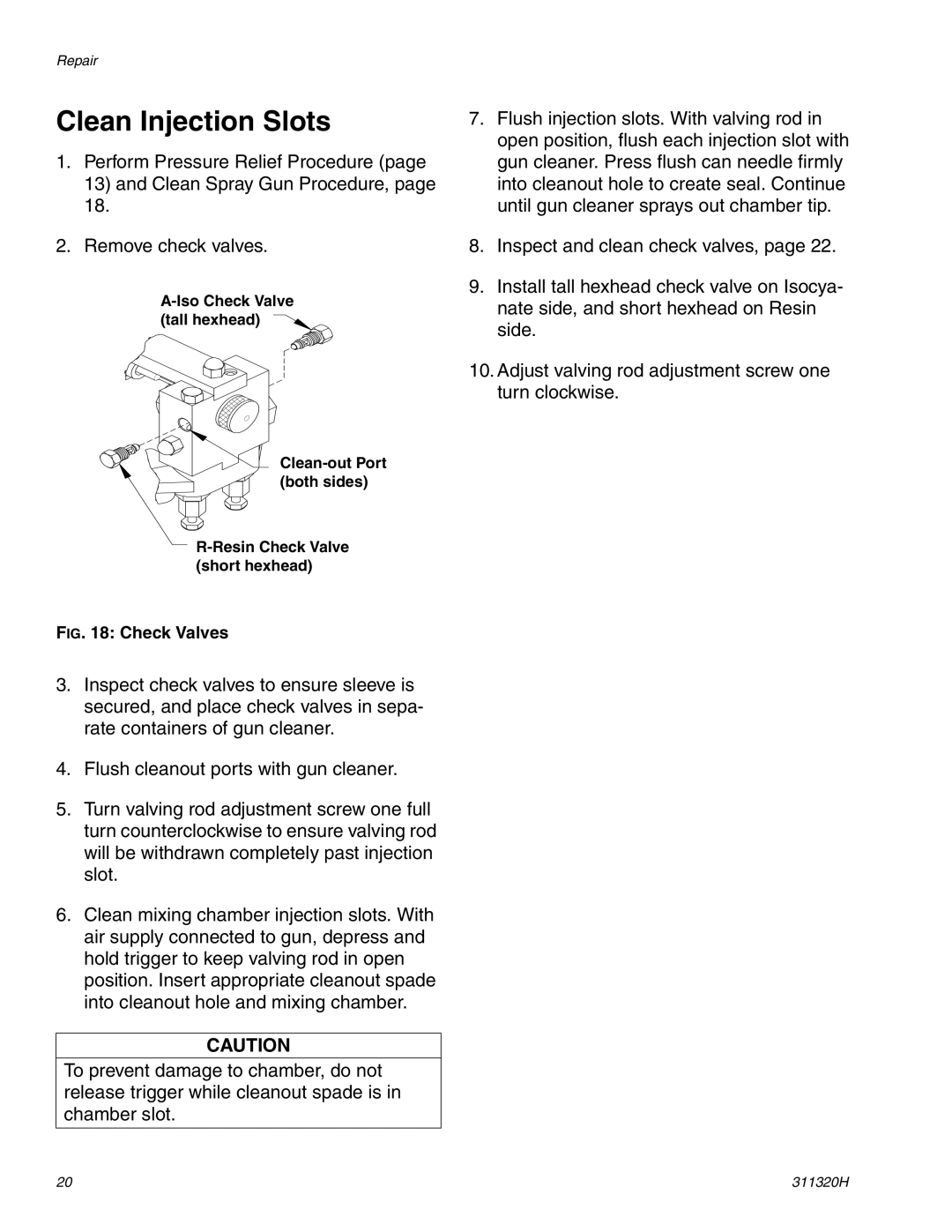

2.Remove check valves.

![]()

FIG. 18: Check Valves

3.Inspect check valves to ensure sleeve is secured, and place check valves in sepa- rate containers of gun cleaner.

4.Flush cleanout ports with gun cleaner.

5.Turn valving rod adjustment screw one full turn counterclockwise to ensure valving rod will be withdrawn completely past injection slot.

6.Clean mixing chamber injection slots. With air supply connected to gun, depress and hold trigger to keep valving rod in open position. Insert appropriate cleanout spade into cleanout hole and mixing chamber.

CAUTION

To prevent damage to chamber, do not release trigger while cleanout spade is in chamber slot.

7.Flush injection slots. With valving rod in open position, flush each injection slot with gun cleaner. Press flush can needle firmly into cleanout hole to create seal. Continue until gun cleaner sprays out chamber tip.

8.Inspect and clean check valves, page 22.

9.Install tall hexhead check valve on Isocya- nate side, and short hexhead on Resin side.

10.Adjust valving rod adjustment screw one turn clockwise.

20 | 311320H |