Tip Installation

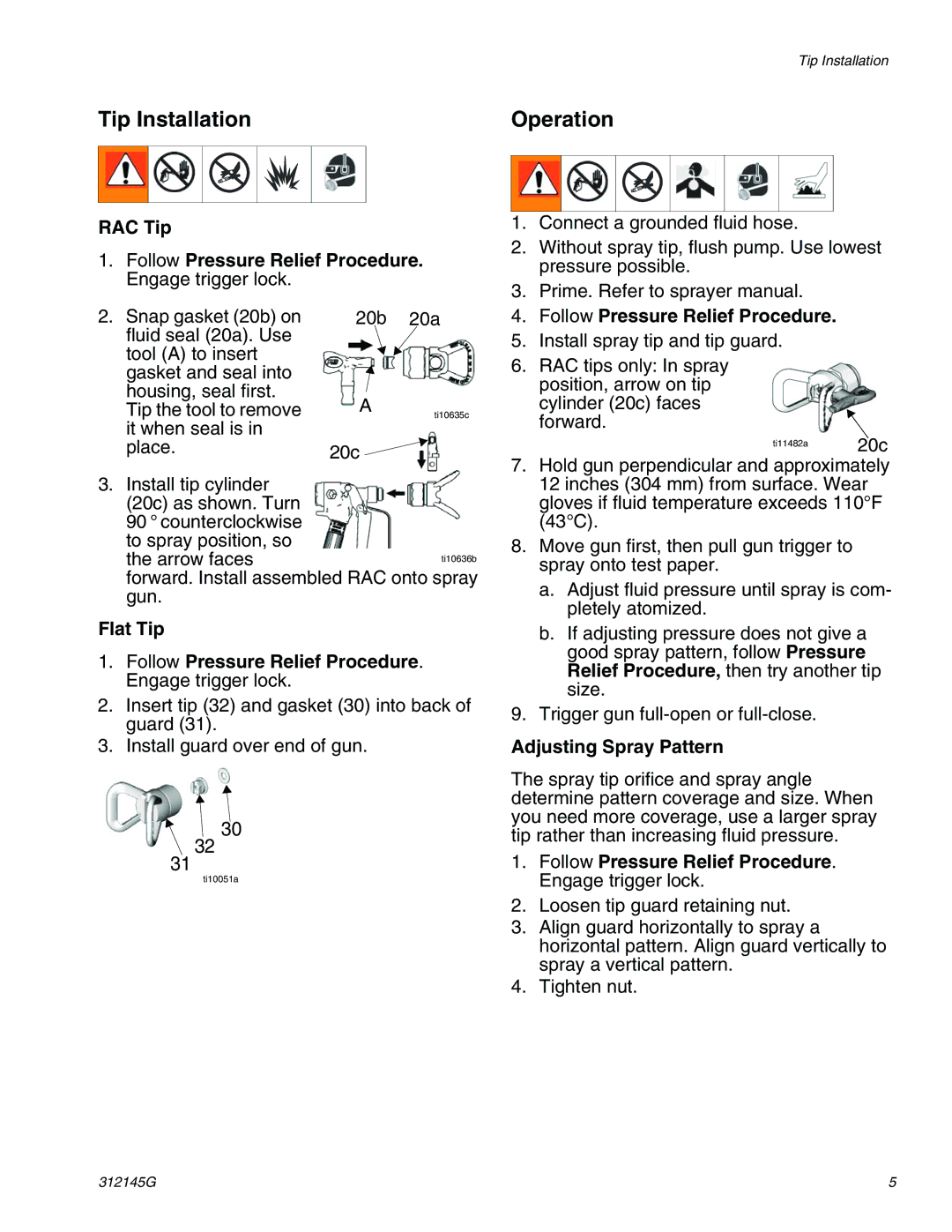

RAC Tip

1.Follow Pressure Relief Procedure. Engage trigger lock.

Tip Installation

Operation

1. | Connect a grounded fluid hose. |

2. | Without spray tip, flush pump. Use lowest |

| pressure possible. |

3. | Prime. Refer to sprayer manual. |

2.Snap gasket (20b) on fluid seal (20a). Use tool (A) to insert gasket and seal into housing, seal first. Tip the tool to remove it when seal is in place.

20b 20a

A

ti10635c

20c ![]()

4. | Follow Pressure Relief Procedure. |

5. | Install spray tip and tip guard. |

6. | RAC tips only: In spray |

| position, arrow on tip |

| cylinder (20c) faces |

forward.

ti11482a20c

7. Hold gun perpendicular and approximately |

3.Install tip cylinder (20c) as shown. Turn 90 ° counterclockwise to spray position, so

the arrow faces | ti10636b |

forward. Install assembled RAC onto spray gun.

Flat Tip

1.Follow Pressure Relief Procedure. Engage trigger lock.

2.Insert tip (32) and gasket (30) into back of guard (31).

3.Install guard over end of gun.

![]() 30 32

30 32

31

ti10051a

12 inches (304 mm) from surface. Wear |

gloves if fluid temperature exceeds 110°F |

(43°C). |

8. Move gun first, then pull gun trigger to |

spray onto test paper. |

a. Adjust fluid pressure until spray is com- |

pletely atomized. |

b. If adjusting pressure does not give a |

good spray pattern, follow Pressure |

Relief Procedure, then try another tip |

size. |

9. Trigger gun |

Adjusting Spray Pattern

The spray tip orifice and spray angle determine pattern coverage and size. When you need more coverage, use a larger spray tip rather than increasing fluid pressure.

1.Follow Pressure Relief Procedure. Engage trigger lock.

2.Loosen tip guard retaining nut.

3.Align guard horizontally to spray a horizontal pattern. Align guard vertically to spray a vertical pattern.

4.Tighten nut.

312145G | 5 |