Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever you see this symbol.

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

1.Verify pump feeding valve is stopped and discon- nected from, or locked out of it’s driver.

2.Using a wrench, slowly loosen inlet nut.

3.Then, using a wrench, slowly loosen each port nut.

Setup

The divider valve is shipped ready to install in your sys- tem. It has been

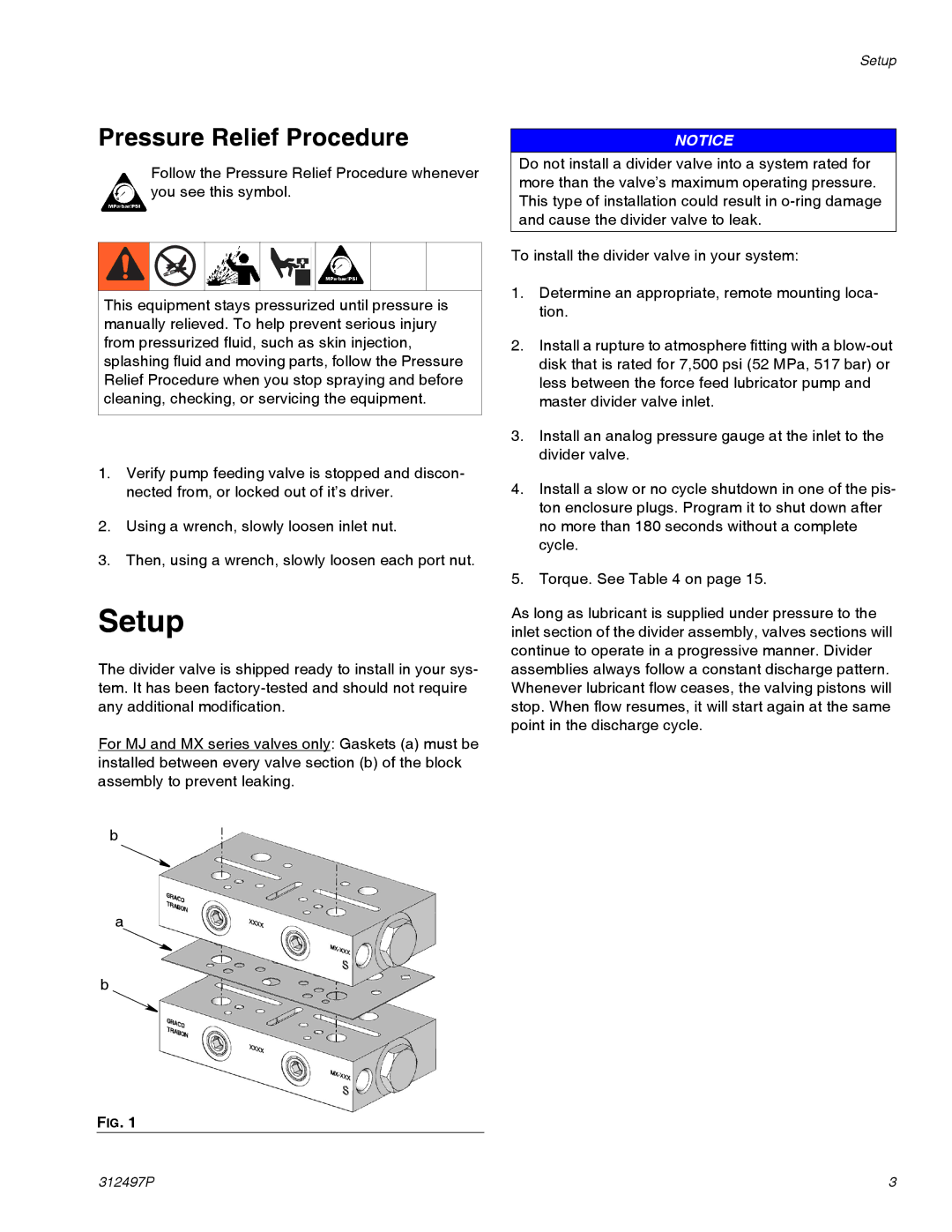

For MJ and MX series valves only: Gaskets (a) must be installed between every valve section (b) of the block assembly to prevent leaking.

b

a

b

FIG. 1

Setup

NOTICE

Do not install a divider valve into a system rated for more than the valve’s maximum operating pressure. This type of installation could result in

To install the divider valve in your system:

1.Determine an appropriate, remote mounting loca- tion.

2.Install a rupture to atmosphere fitting with a

3.Install an analog pressure gauge at the inlet to the divider valve.

4.Install a slow or no cycle shutdown in one of the pis- ton enclosure plugs. Program it to shut down after no more than 180 seconds without a complete cycle.

5.Torque. See Table 4 on page 15.

As long as lubricant is supplied under pressure to the inlet section of the divider assembly, valves sections will continue to operate in a progressive manner. Divider assemblies always follow a constant discharge pattern. Whenever lubricant flow ceases, the valving pistons will stop. When flow resumes, it will start again at the same point in the discharge cycle.

312497P | 3 |