Setup

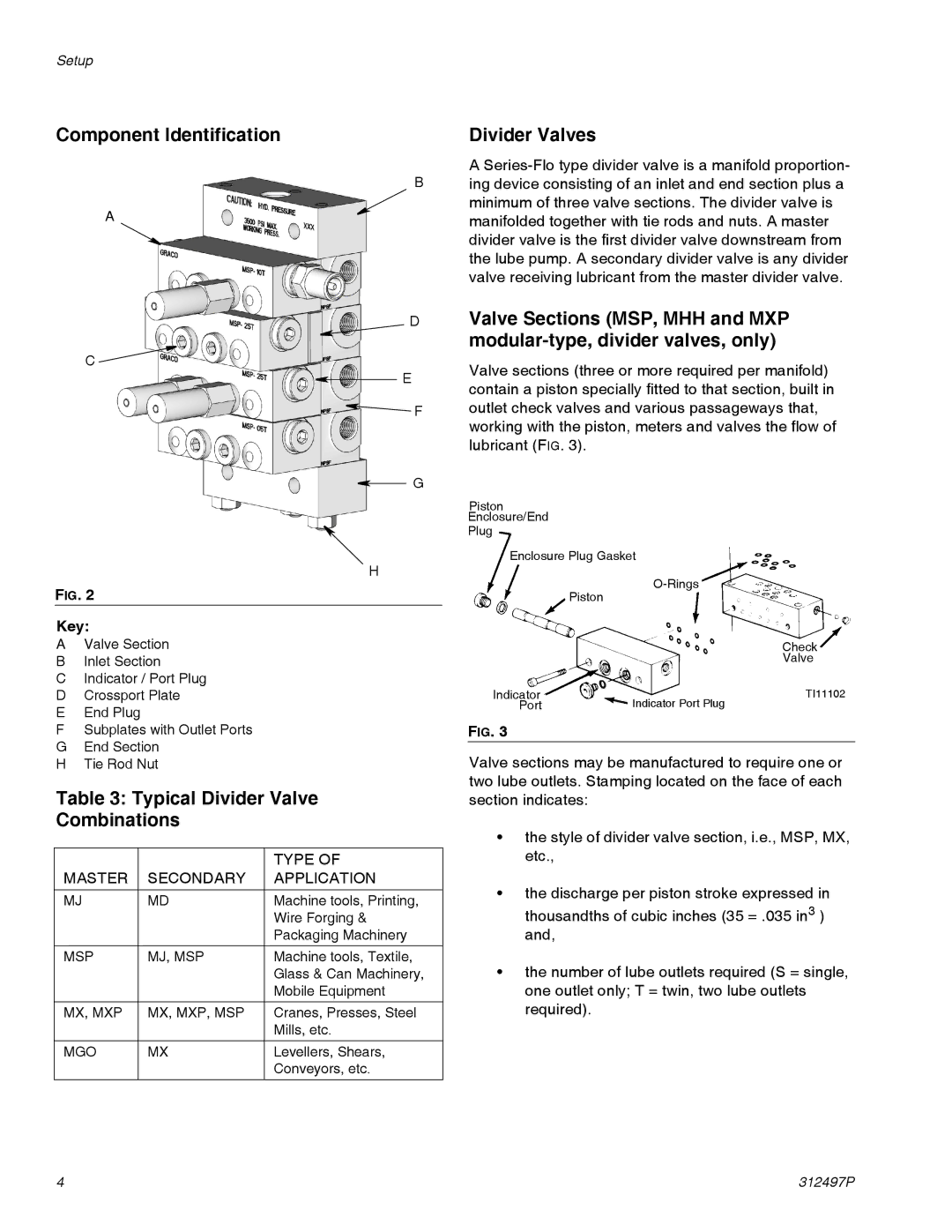

Component Identification

B

A

D

C ![]()

E

![]() F

F

G

H

FIG. 2

Key:

AValve Section

BInlet Section

CIndicator / Port Plug

DCrossport Plate

EEnd Plug

FSubplates with Outlet Ports

GEnd Section

HTie Rod Nut

Table 3: Typical Divider Valve

Combinations

|

| TYPE OF |

MASTER | SECONDARY | APPLICATION |

MJ | MD | Machine tools, Printing, |

|

| Wire Forging & |

|

| Packaging Machinery |

MSP | MJ, MSP | Machine tools, Textile, |

|

| Glass & Can Machinery, |

|

| Mobile Equipment |

MX, MXP | MX, MXP, MSP | Cranes, Presses, Steel |

|

| Mills, etc. |

|

|

|

MGO | MX | Levellers, Shears, |

|

| Conveyors, etc. |

Divider Valves

A

Valve Sections (MSP, MHH and MXP

Valve sections (three or more required per manifold) contain a piston specially fitted to that section, built in outlet check valves and various passageways that, working with the piston, meters and valves the flow of lubricant (FIG. 3).

Piston

Enclosure/End

Plug

Enclosure Plug Gasket

Piston

Check

Valve

Indicator | TI11102 |

Port | Indicator Port Plug |

FIG. 3

Valve sections may be manufactured to require one or two lube outlets. Stamping located on the face of each section indicates:

•the style of divider valve section, i.e., MSP, MX, etc.,

•the discharge per piston stroke expressed in thousandths of cubic inches (35 = .035 in3 ) and,

•the number of lube outlets required (S = single, one outlet only; T = twin, two lube outlets required).

4 | 312497P |