SECTION 11 − MAINTENANCE AND TROUBLESHOOTING

11-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months

Replace

Unreadable

Labels

Clean

And

Tighten

Weld

Terminals

Repair Or

Replace

Cracked

Weld

Cable

Replace | Gas | Gun | |

Cracked |

| Hose And | |

| Cable | ||

Parts |

| Fittings | |

|

|

6 Months

Blow Out Or Vacuum

Inside. During HeavyOR

Service, Clean

Monthly

Clean

Drive

Rolls

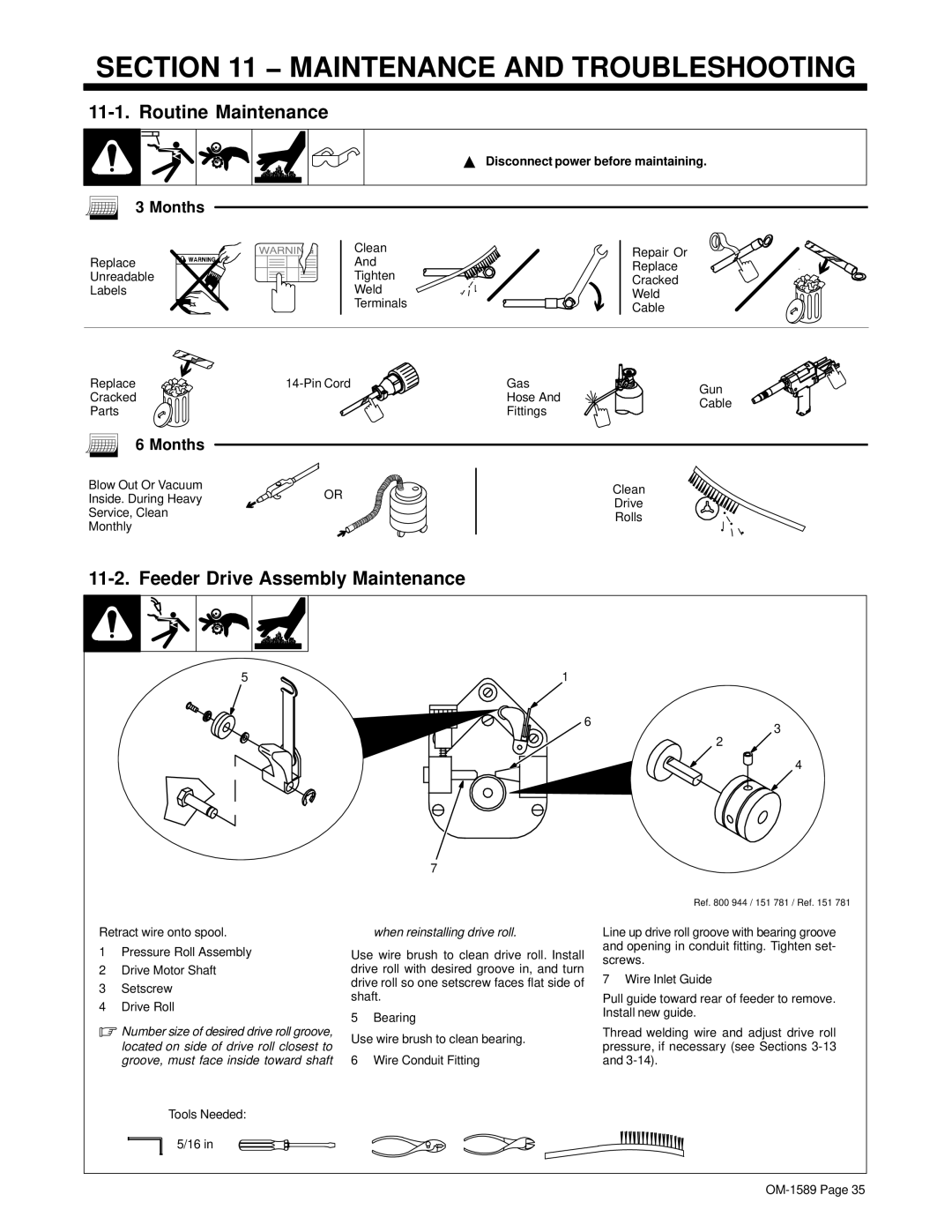

11-2. Feeder Drive Assembly Maintenance

5 | 1 |

6

3

2 ![]()

![]() 4

4

7

Retract wire onto spool.

1Pressure Roll Assembly

2Drive Motor Shaft

3Setscrew

4Drive Roll

.Number size of desired drive roll groove, located on side of drive roll closest to groove, must face inside toward shaft

when reinstalling drive roll.

Use wire brush to clean drive roll. Install drive roll with desired groove in, and turn drive roll so one setscrew faces flat side of shaft.

5 Bearing

Use wire brush to clean bearing.

6 Wire Conduit Fitting

Ref. 800 944 / 151 781 / Ref. 151 781

Line up drive roll groove with bearing groove and opening in conduit fitting. Tighten set- screws.

7 Wire Inlet Guide

Pull guide toward rear of feeder to remove. Install new guide.

Thread welding wire and adjust drive roll pressure, if necessary (see Sections

Tools Needed:

5/16 in