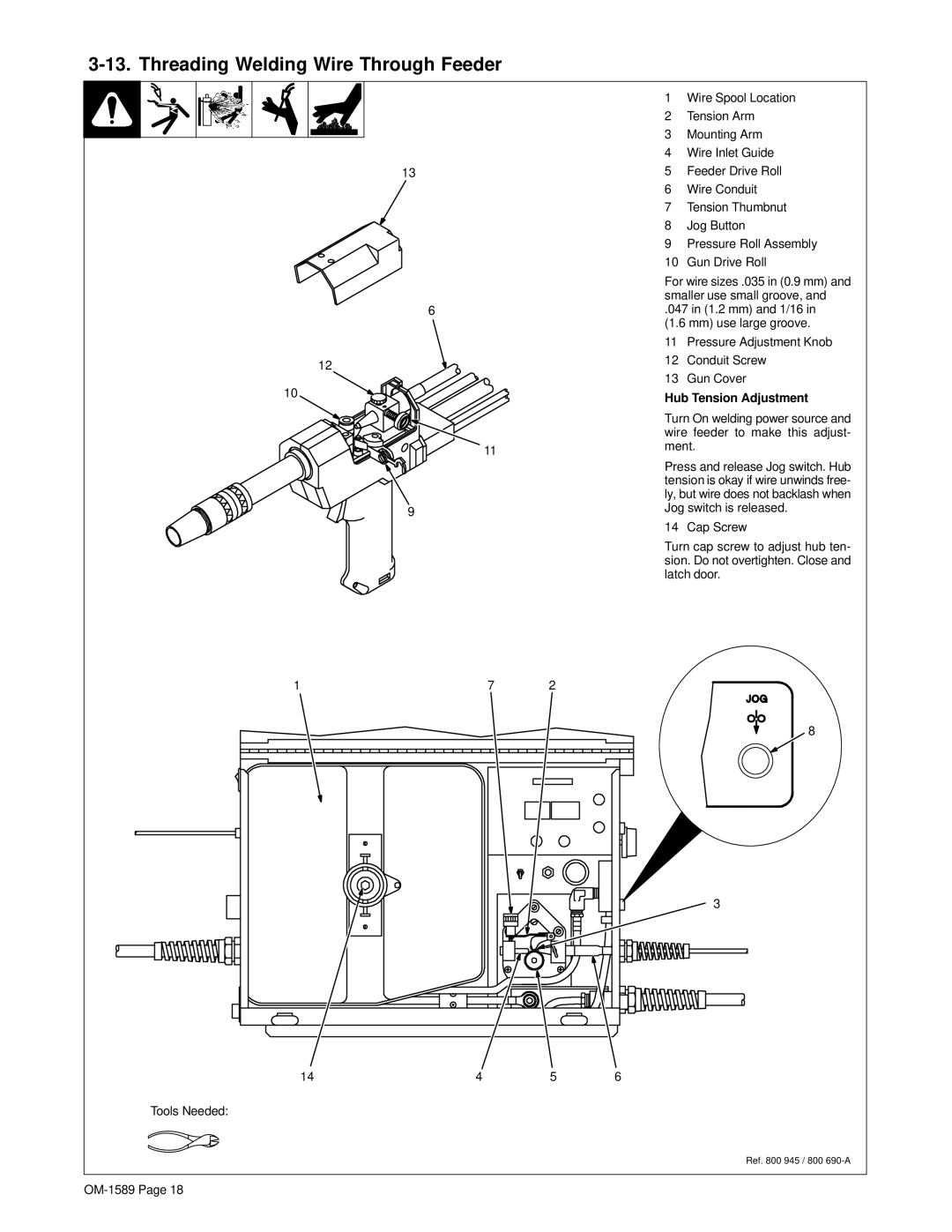

3-13. Threading Welding Wire Through Feeder

13

6

12

10

11

9

1 | 7 | 2 |

1Wire Spool Location

2Tension Arm

3Mounting Arm

4Wire Inlet Guide

5Feeder Drive Roll

6Wire Conduit

7Tension Thumbnut

8Jog Button

9Pressure Roll Assembly

10Gun Drive Roll

For wire sizes .035 in (0.9 mm) and smaller use small groove, and

.047 in (1.2 mm) and 1/16 in

(1.6 mm) use large groove.

11Pressure Adjustment Knob

12Conduit Screw

13Gun Cover

Hub Tension Adjustment

Turn On welding power source and wire feeder to make this adjust- ment.

Press and release Jog switch. Hub tension is okay if wire unwinds free- ly, but wire does not backlash when Jog switch is released.

14 Cap Screw

Turn cap screw to adjust hub ten- sion. Do not overtighten. Close and latch door.

8

3

14 | 4 | 5 | 6 |

Tools Needed:

Ref. 800 945 / 800