SECTION 4 − OPERATION

4-1. Operational Terms

NOTE

See Menu Guide for detailed programming steps.

The following is a list of terms and their definitions as they apply to this wire feeder:

General Terms: |

|

Adaptive Pulse Welding | The wire feeder automatically regulates pulse frequency to maintain a constant arc length, regardless |

| of change in welding wire stickout. |

Cold Wire Jog | When weld amperage is not present, wire feeds for about three seconds at set wire feed speed. Then |

| the welding power source contactor deenergizes and wire continues to feed at the wire jog speed. |

Inductance | As inductance increases, arc on time increases, and the weld puddle becomes more fluid. |

Trim | Arc length adjustment in pulse welding. Increasing trim increases the actual arc length. Trim is re- |

| placed by volts in MIG programs. |

Synergic | The operator programs pulse parameters for a specific wire feed speed. The wire feeder determines |

| the pulse parameters between these wire feed speed increments. |

Side Panel Terms: |

|

Card Mode | Is used to select use of the optional data card storage and retrieval capabilities. |

Dual Schedule Mode | Is used to select a pair of programs that can be used together. |

Process Mode | Is used to select the type of process to be used, including Pulse, Adaptive Pulse, or Mig. |

Sequence Mode | Is used to select and program the weld sequences which include weld, crater, burnback, postflow, |

| preflow, and |

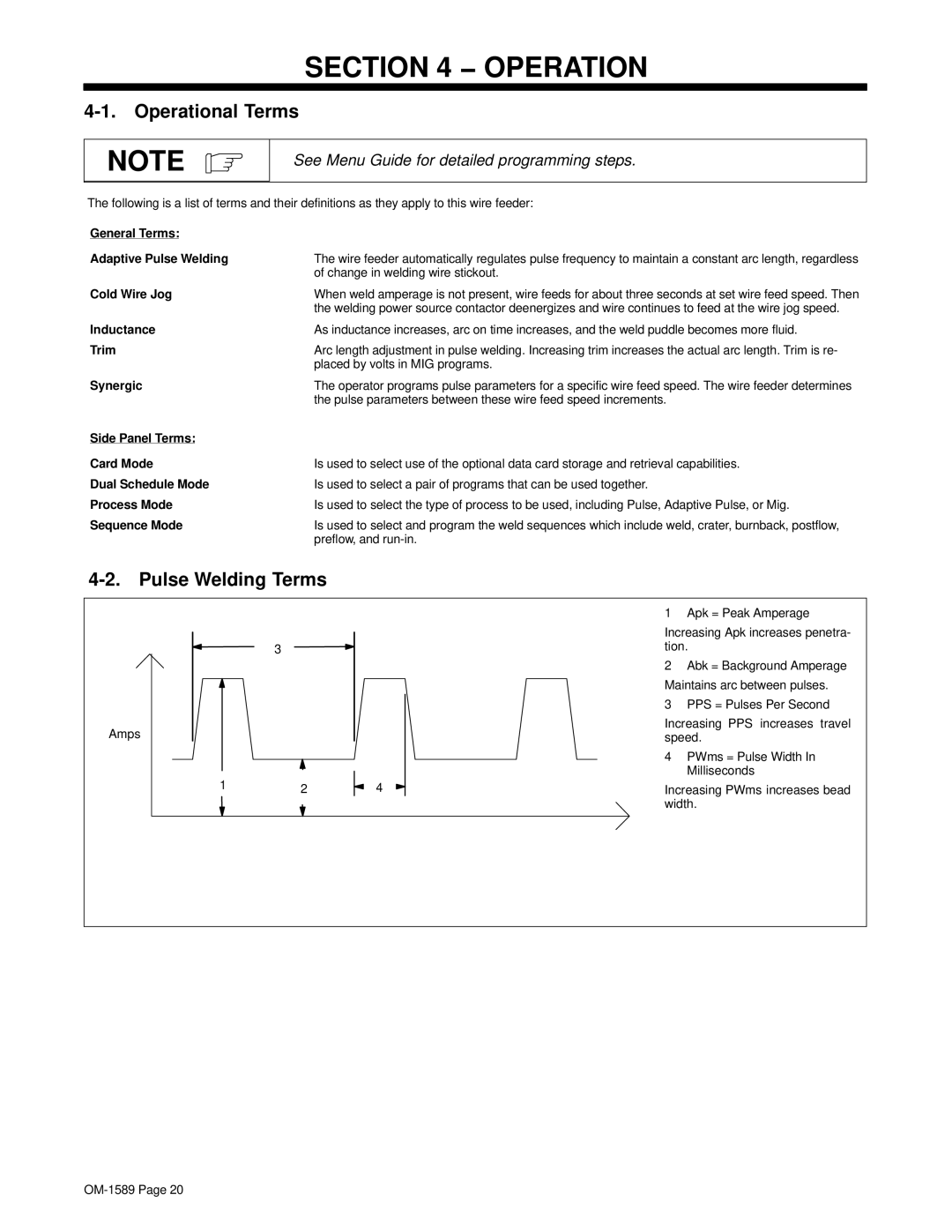

4-2. Pulse Welding Terms

Amps

3

12

4

1 Apk = Peak Amperage

Increasing Apk increases penetra- tion.

2Abk = Background Amperage Maintains arc between pulses.

3PPS = Pulses Per Second

Increasing PPS increases travel speed.

4PWms = Pulse Width In Milliseconds

Increasing PWms increases bead width.