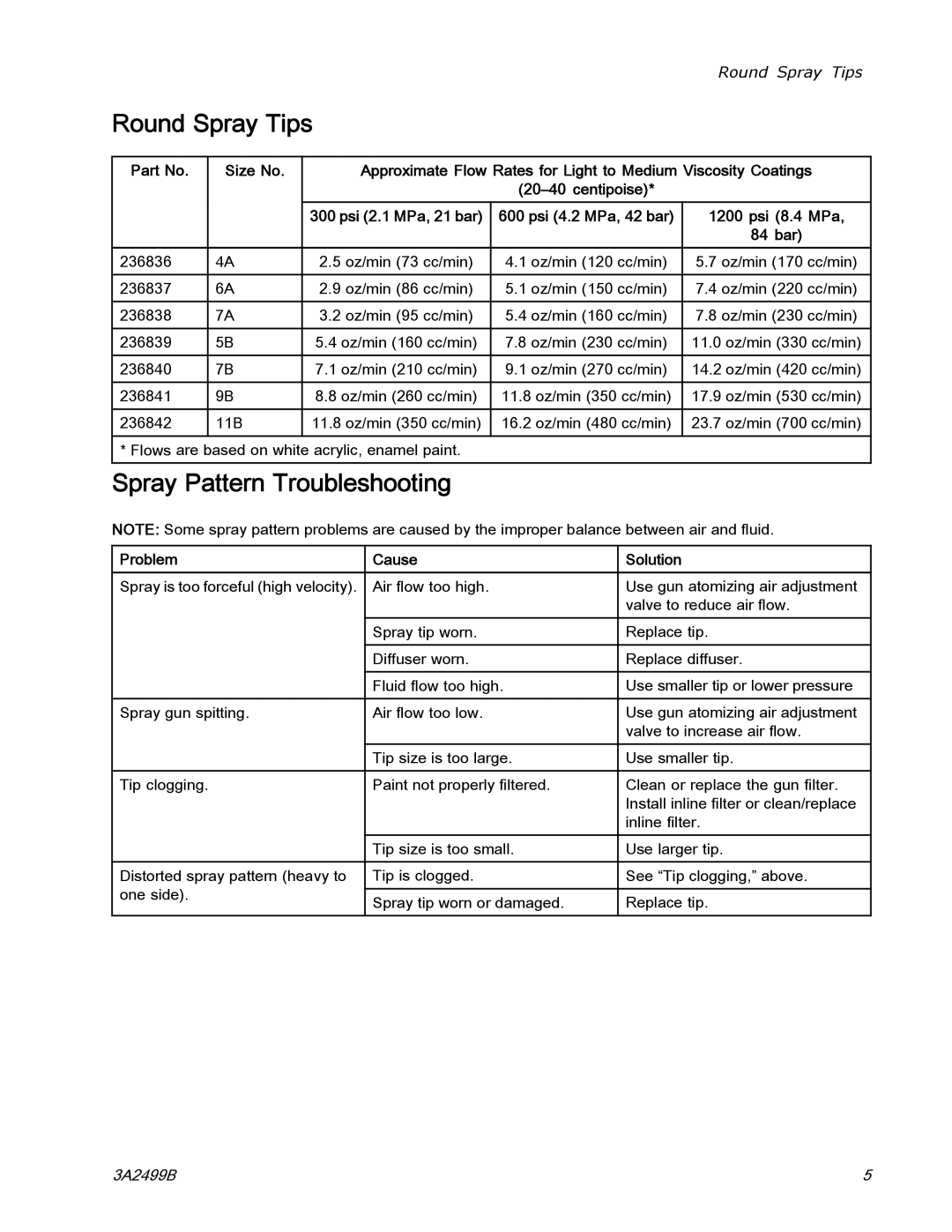

Round Spray Tips

Round Spray Tips

Part No. | Size No. | Approximate Flow Rates for Light to Medium Viscosity Coatings | ||||

|

|

|

|

|

| |

|

| 300 psi (2.1 MPa, 21 bar) |

| 600 psi (4.2 MPa, 42 bar) |

| 1200 psi (8.4 MPa, |

|

|

|

| |||

|

|

|

|

|

| 84 bar) |

|

|

|

|

|

|

|

236836 | 4A | 2.5 oz/min (73 cc/min) |

| 4.1 oz/min (120 cc/min) |

| 5.7 oz/min (170 cc/min) |

|

|

|

|

|

|

|

236837 | 6A | 2.9 oz/min (86 cc/min) |

| 5.1 oz/min (150 cc/min) |

| 7.4 oz/min (220 cc/min) |

|

|

|

|

|

|

|

236838 | 7A | 3.2 oz/min (95 cc/min) |

| 5.4 oz/min (160 cc/min) |

| 7.8 oz/min (230 cc/min) |

|

|

|

|

|

|

|

236839 | 5B | 5.4 oz/min (160 cc/min) |

| 7.8 oz/min (230 cc/min) |

| 11.0 oz/min (330 cc/min) |

|

|

|

|

|

|

|

236840 | 7B | 7.1 oz/min (210 cc/min) |

| 9.1 oz/min (270 cc/min) |

| 14.2 oz/min (420 cc/min) |

|

|

|

|

|

|

|

236841 | 9B | 8.8 oz/min (260 cc/min) |

| 11.8 oz/min (350 cc/min) |

| 17.9 oz/min (530 cc/min) |

|

|

|

|

|

|

|

236842 | 11B | 11.8 oz/min (350 cc/min) |

| 16.2 oz/min (480 cc/min) |

| 23.7 oz/min (700 cc/min) |

|

|

|

|

|

|

|

* Flows are based on white acrylic, enamel paint.

Spray Pattern Troubleshooting

NOTE: Some spray pattern problems are caused by the improper balance between air and fluid.

Problem | Cause | Solution |

|

|

|

Spray is too forceful (high velocity). | Air flow too high. | Use gun atomizing air adjustment |

|

| valve to reduce air flow. |

| Spray tip worn. | Replace tip. |

| Diffuser worn. | Replace diffuser. |

| Fluid flow too high. | Use smaller tip or lower pressure |

Spray gun spitting. | Air flow too low. | Use gun atomizing air adjustment |

|

| valve to increase air flow. |

| Tip size is too large. | Use smaller tip. |

|

|

|

Tip clogging. | Paint not properly filtered. | Clean or replace the gun filter. |

|

| Install inline filter or clean/replace |

|

| inline filter. |

| Tip size is too small. | Use larger tip. |

|

|

|

Distorted spray pattern (heavy to | Tip is clogged. | See “Tip clogging,” above. |

one side). | Spray tip worn or damaged. | Replace tip. |

| ||

|

|

|

3A2499B | 5 |