Repair

12.Torque cartridge (3) to specified torque listed in the following table.

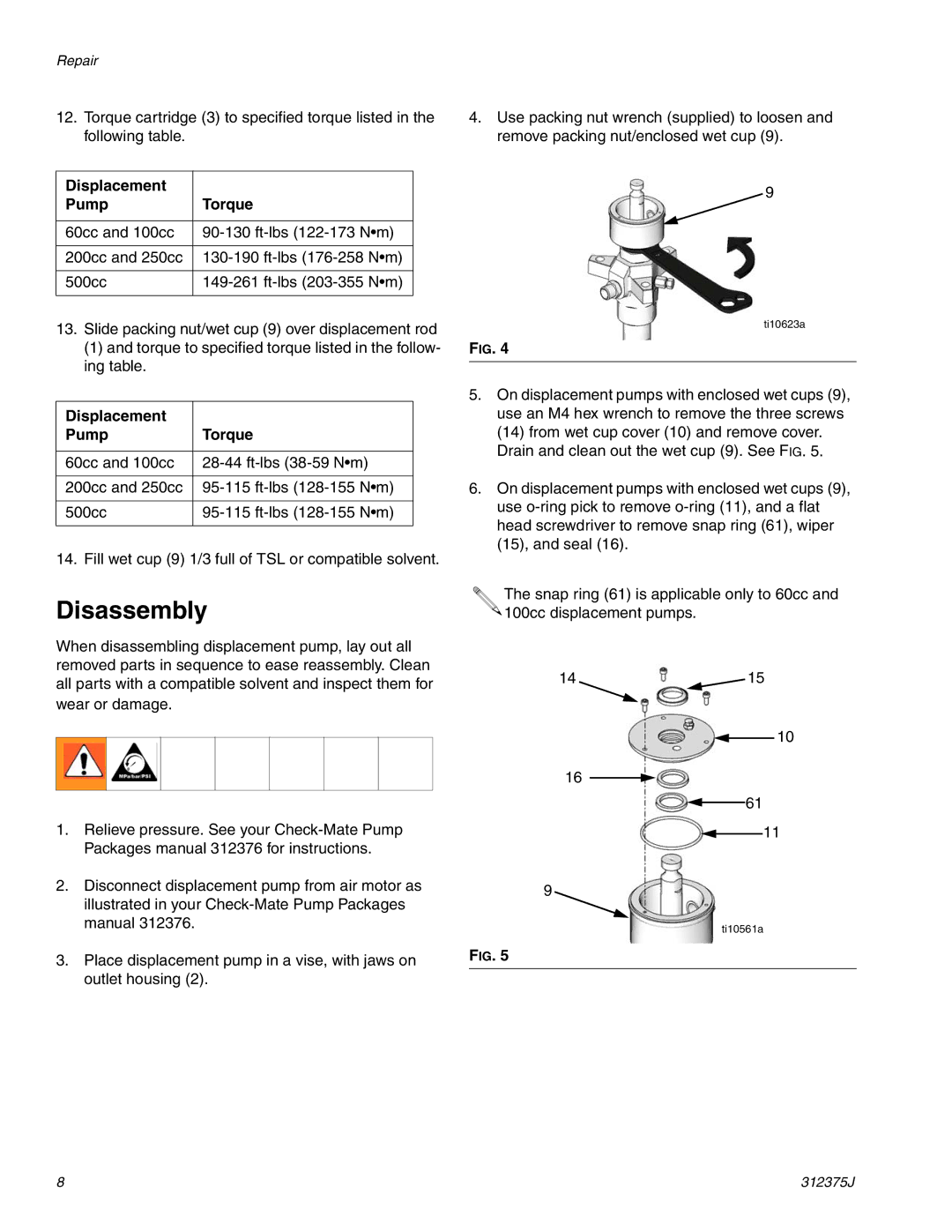

4.Use packing nut wrench (supplied) to loosen and remove packing nut/enclosed wet cup (9).

Displacement |

|

Pump | Torque |

|

|

60cc and 100cc | |

|

|

200cc and 250cc | |

|

|

500cc | |

|

|

13.Slide packing nut/wet cup (9) over displacement rod

(1) and torque to specified torque listed in the follow- ing table.

Displacement |

|

Pump | Torque |

|

|

60cc and 100cc | |

|

|

200cc and 250cc | |

|

|

500cc | |

|

|

14. Fill wet cup (9) 1/3 full of TSL or compatible solvent.

Disassembly

When disassembling displacement pump, lay out all removed parts in sequence to ease reassembly. Clean all parts with a compatible solvent and inspect them for wear or damage.

1.Relieve pressure. See your

2.Disconnect displacement pump from air motor as illustrated in your

3.Place displacement pump in a vise, with jaws on outlet housing (2).

9

ti10623a

FIG. 4

5.On displacement pumps with enclosed wet cups (9), use an M4 hex wrench to remove the three screws (14) from wet cup cover (10) and remove cover.

Drain and clean out the wet cup (9). See FIG. 5.

6.On displacement pumps with enclosed wet cups (9), use

The snap ring (61) is applicable only to 60cc and ![]()

![]() 100cc displacement pumps.

100cc displacement pumps.

1415

10

16

61

11

9

ti10561a

FIG. 5

8 | 312375J |