5435, 5430, 310584D, T1-Titanium specifications

Graco Inc is a leading manufacturer in the field of fluid handling systems, known for its innovative and reliable products. One of its standout offerings is the T1-Titanium paint sprayers, specifically the models 310584D, 5430, and 5435. These sprayers cater to professionals and DIY enthusiasts alike, providing exceptional performance for various painting applications, including residential, commercial, and industrial projects.The T1-Titanium series is characterized by its lightweight and durable design, highlighting the use of titanium in its construction. This material not only ensures longevity but also makes the sprayers easier to handle, reducing fatigue during extended use. The models are engineered for high efficiency, allowing users to complete projects faster while maintaining a quality finish.

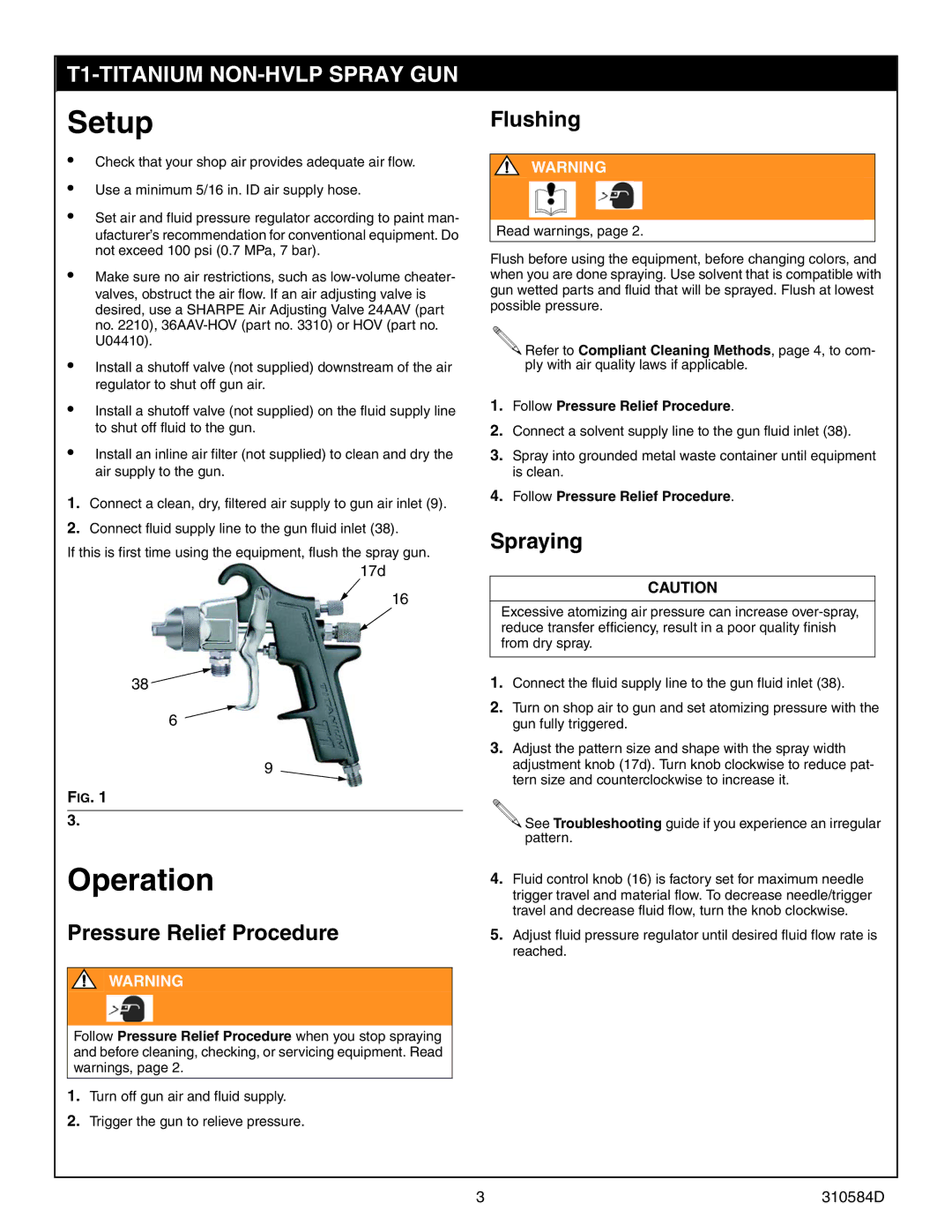

One of the main features of the T1-Titanium sprayers is their adjustable pressure control. This technology gives users the flexibility to adjust the spray pattern and flow rate according to the specific requirements of their projects. Whether applying broad strokes on large surfaces or dealing with intricate detailing, the models effectively accommodate various needs, ensuring optimal coverage and reduced overspray.

The 310584D, 5430, and 5435 also integrate Graco's ProConnect system, which allows for quick and easy replacement of the pump without the need for additional tools. This feature significantly reduces downtime, enabling painters to keep projects on schedule. Additionally, the models are equipped with a robust filtration system that ensures the sprayers operate cleanly, minimizing clogs and extending the overall life of the equipment.

Another important characteristic of these sprayers is their versatility; they are compatible with a wide range of coatings, including stains, sealers, and latex paints. This adaptability makes them ideal for various applications, from residential repaints to large-scale commercial projects.

In summary, Graco Inc's T1-Titanium paint sprayers, particularly the 310584D, 5430, and 5435 models, are exemplary products in the painting equipment market. With their lightweight titanium construction, adjustable pressure control, ProConnect system, and versatility with coatings, these sprayers are designed to meet the demands of both professionals and DIYers, delivering exceptional results with ease and efficiency.